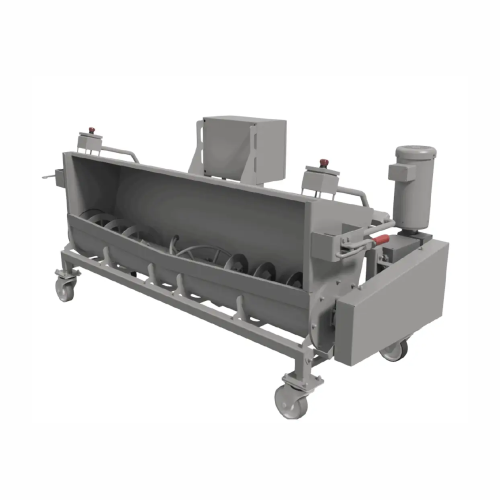

Curd unloader for dairy production

Streamline your cheese production with efficient curd unloading and transfer, ensuring smooth handling from draining tables to downstream processes with minimal product loss.

Transfers and Handles Cheese Curds Efficiently

The RELCO® Curd Pick-Up Unloader is specifically engineered to facilitate the efficient transfer of cheese curds within high-throughput dairy production facilities. It incorporates a high-capacity hopper coupled with a ribbon auger, which gently moves curds without compromising their texture. This equipment can seamlessly transfer curds to blockformers, barrels, or manual hooping processes, supporting a variety of cheese types such as cheddar, gouda, and mozzarella. The unit’s flexibility is evident with its mobility options, allowing movement on casters or integration into an overhead rail system, making it adaptable to various processing layouts. Operational modes include air blowing, vacuum, or mechanical auger systems, catering to different processing needs. Built to comply with 3A standards and USDA guidelines, the unloader ensures hygiene and safety. Optional features like frame swivel casters and multiple diameter star valves further enhance its customization, enabling it to meet specific production requirements while maintaining continuous operation and reducing manual handling.

Benefits

- Enhances production efficiency by minimizing curd handling time.

- Reduces manual labor with easy maneuverability and automated options.

- Supports various cheese production processes with flexible transfer methods.

- Complies with strict hygiene standards, ensuring product safety and quality.

- Customizable features accommodate diverse production layouts and capacities.

- Applications

- Food, Beverage, Dairy, Cheese products

- End products

- Feta cheese, Brie cheese, Gouda cheese wheels, Mozzarella cheese, Ricotta cheese, Swiss cheese, Processed cheese slices, Cheddar cheese blocks, Cottage cheese

- Steps before

- Curd Draining, Salting

- Steps after

- Blockforming, Hoop Filling, Barrel Filling, Manual Hooping

- Input ingredients

- salted curd, cheese draining table, unsalted curd

- Output ingredients

- blockformers, 640 lb hoop filling, 500 lb barrel filling, manual hooping, cheese blocks, cheese barrels

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Hopper Capacity

- High

- Automation

- Manual/PLC-controlled

- Transfer Method

- Air (blowing), Air (vacuum), Mechanical (auger)

- Material Construction

- Stainless steel

- Compliance

- 3A standards, USDA guidelines

- Curd Transfer Capacity

- Multiple widths available

- Switch Type

- Proximity switches

- Casters

- Swivel casters

- Star Valve Diameter

- 10” / 12”

- Movement Option

- Manual/Overhead Rail System

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- Not applicable / Optional

- Cleaning method

- Manual

- Changeover time

- Quick release / Fast

- Corrosive resistance

- Stainless steel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies by model

- Hopper capacity

- High capacity

- Discharge method

- Air (blowing/vacuum), Mechanical (auger)

- Width

- Multiple widths available

- Movability

- Manual, Overhead Rail System

- Auger type

- Ribbon Auger

- Frame with swivel casters

- Yes

- Frame with overhead rail system

- Yes