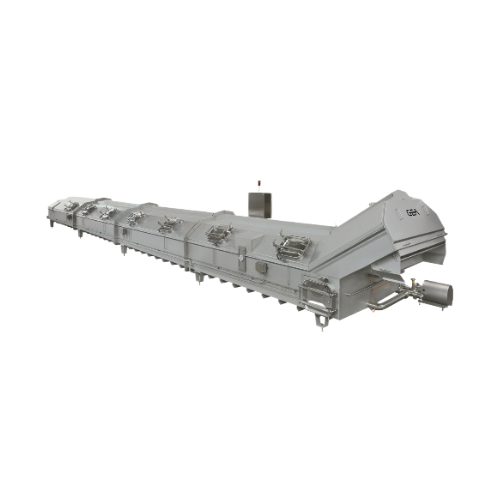

Brining vats for pasta filata cheese

Enhance your cheese production with modular brining vats, designed for precise salt addition and cooling, ensuring optimal flavor and texture for pasta filata cheeses.

Brines and Cools Pasta Filata Cheeses

The modular brining vats from GEA offer an innovative solution designed to enhance your cheese production line. Constructed from AISI 316 stainless steel, these vats are engineered for both durability and hygiene. They feature a conveyor system that transfers cheeses through the brine, supported by adjustable water sprayers for optimal salt distribution and cooling. This setup allows for continuous, high-capacity processing of mozzarella, provolone, and other pasta filata cheeses. The system’s automation is driven by an electrical motor-driven cruising mechanism, ensuring seamless integration into your existing line with options for single or multi-level configurations. Additionally, the vats are equipped with a centrifugal pump that simultaneously recycles cooling brine and recovers cleaning solutions, supported by rotary washing turbines for easy cleaning. Each configuration is customized to match your production rate and cheese type, offering flexibility and efficiency without compromising safety, thanks to comprehensive mechanical and electromechanical protections.

Benefits

- Enhances production efficiency with continuous, high-capacity operation.

- Reduces labor requirements through automated product transport and brine application.

- Ensures product consistency with precise salt distribution and cooling control.

- Facilitates hygienic operations with integrated CIP system for quick cleaning.

- Offers flexible scalability with modular, customizable configurations to match production demands.

- Applications

- Cheese, Pasta filata cheeses

- End products

- Burrata, Mozzarella, Caciocavallo, Provolone, Scamorza, String cheese

- Steps before

- Cheese Making, Cooling

- Steps after

- Packaging, Labeling, Distribution

- Input ingredients

- pasta filata cheeses, water, salt, brine solution

- Output ingredients

- salted cheese, brined cheese

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Material

- AISI 316 stainless steel

- Capacity

- Modular, adjustable for production rate

- Conveyor System

- Electric motor-driven cruising system

- Automation

- Pneumatic lifting system, adjustable water sprayers

- Cooling System

- Plate heat exchanger for brine water recirculation

- Cleaning Method

- CIP, rotary washing turbines, centrifugal pump

- Safety

- Mechanical and electromechanical protection

- Brining Process

- Multiple levels, customizable configuration

- Working mechanism

- Conveyor with adjustable water sprayers and motorized belt

- Integrated steps

- Conveyor transfer, brine solution immersion, product advancement

- CIP/SIP

- Includes rotary washing turbines and pipework for CIP

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Cleaning method

- CIP

- Energy efficiency

- N/A

- Changeover time

- N/A

- Product movement method

- Pneumatic lifting system for multi-level configurations

- Corrosive resistance (e.g. acids)

- AISI 316 Stainless Steel

- Cleanability

- Designed for easy cleaning

- Product type

- Cheese

- Material

- AISI 316 stainless steel

- Shape

- Modular, configurable on one or multiple levels

- Discharge method

- Motorized belt with modular plastic elements

- Footprint

- Configurable based on production rate and plant layout

- Control system

- Electrical motor-driven cruising system