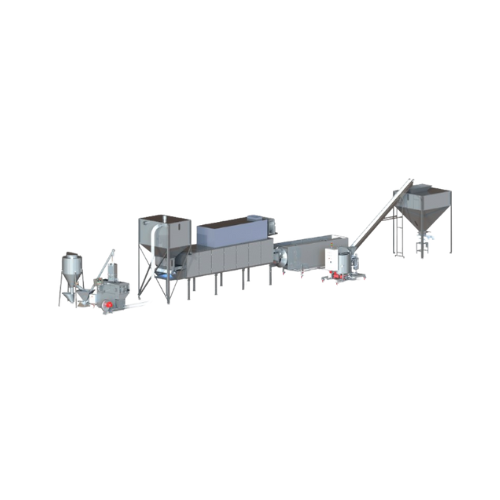

Single-screw high shear extruder

Optimize your snack production with precise control over raw material transformation, from mixing to extrusion, ensuring consistent product quality and efficient throughput.

Extrudes Snacks with Precision and High Throughput

The single screw extruder from Lalesse Extrusion offers a high shear approach to snack manufacturing, ideal for producing diverse snacks like cereal puffs, crispy rice snacks, and flavored popcorn. Specializing in precision control of texture and density, this equipment supports capacities ranging from 80 to 300 kg per hour, with the actual throughput depending on the raw materials and snack shapes. The extruder integrates seamlessly into continuous, automated processing lines with variable speed control and full water-cooled processes. Its advanced direct drive system eliminates the need for V-belts, providing robust performance ideal for high-speed operations. Additionally, the split sleeve system enhances cost-efficiency, and the use of die inserts instead of plates offers a cost-effective customization option for various snack shapes. The machine is engineered for easy maintenance, with features like a hollow main shaft for quick screw removal, ensuring minimal downtime in your production line.

Benefits

- Enhances production efficiency by maintaining continuous, high-speed operations.

- Offers precise control of snack texture and density for consistent product quality.

- Minimizes operational costs with energy-efficient direct drive and split sleeve system.

- Facilitates quick changeovers and maintenance, reducing downtime.

- Provides flexible shaping and cost savings through interchangeable die inserts.

- Applications

- Coating materials, Snacks

- End products

- Flavored popcorn, Nut coatings, Crispy rice snacks, Spice coatings, Potato snacks, Cereal puffs, Cheese balls

- Steps before

- Raw Material Feeding, Water Addition, Mixing

- Steps after

- Drying, Coating, Packing

- Input ingredients

- raw materials, water, oil, flavour powder

- Output ingredients

- mixed raw materials, extruded snacks, dried snacks, flavoured snacks

- Market info

- Lalesse is known for manufacturing automated storage and retrieval systems (AS/RS) and providing efficient, tailored logistics solutions for warehouses, enhancing operational efficiency and optimizing storage management.

- Capacity (Mixer)

- Dependent on raw material

- Screw Feeder/Transport

- Yes

- Automation

- Auto water feeding

- Capacity (Extruder)

- 80–300 kg/h

- Extrusion Type

- Single screw

- Speed Control

- Variable

- Pressure Settings

- Variable

- Water Cooling

- Full water cooled process

- Direct Drive System

- Yes

- Drum Dryer Capacity

- 200 kg/h

- Belt Dryer Capacity

- 300–2000 kg/h

- Dryer Heating Type

- Infrared / Hot air

- Coating Drum Size

- Various diameters

- Slurry System

- On-demand

- Buffer Type

- Vertical buffer silo

- Buffer Discharge

- Vibration feeder

- Working Mechanism

- Vertical grits mixer uses Archimedes screw

- Ribbon mixer with double action ribbon

- Integrated Steps

- Mixing with water addition, extrusion, drying, flavour coating

- CIP Principles

- Easy cleaning especially for ribbon mixer

- Batch vs Inline Flow

- Continuous operation recommended

- Automation Level

- Variable speed, feed control, auto water feeding

- Energy Efficiency

- Optimized for cost-efficiency

- Temperature Control

- Drum dryer with heat quantity control

- Belt dryer with heat exchanger

- Buffer Capacity

- Use of vertical buffer silo

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade materials

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Various particle sizes

- Machine footprint

- Compact design

- Mixer type

- Vertical grits / Horizontal ribbon

- Mixer capacity

- Variable

- Mixer cleaning

- Easy access

- Extruder screw type

- Single screw, short screw

- Extruder capacity

- 80–300 kg/h

- Infrared drum dryer capacity

- Approx. 200 kg/h

- Belt dryer capacity

- 300–2000 kg/h

- Buffer type

- Vertical buffer silo with vibration feeder

- Buffer silo volume

- Variable

- Coating drum size

- Variable diameter sizes

- Coating drum profile

- Self-cleaning profile

- Control panel type

- Direct drive system

- Integration possibilities

- Variable speed, feed control

- Pressure settings

- Multiple pressure settings available

- Cooling mechanism

- Full water-cooled process

- Die system

- Die inserts with holder

- Sleeve system

- Split sleeve system

- Automation

- Slurry on-demand system

- Mixing types

- Vertical grits mixer, Horizontal ribbon mixer

- Weight measurement

- Weight sensors

- Dryer type

- Infrared drum dryer, Belt dryer