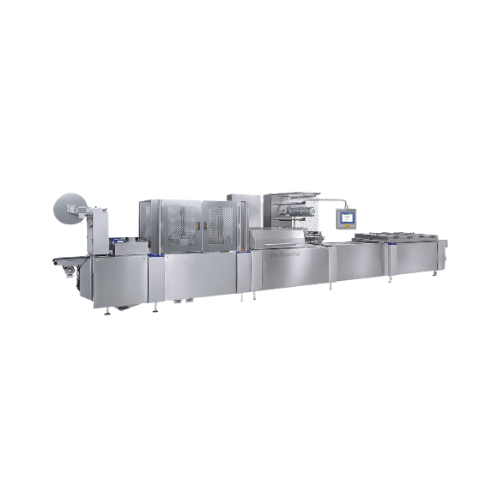

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system designed for high-speed, adaptable processing of diverse food products, ensuring flexible operations and superior sealing integrity for reliable preservation.

Thermoforms, Seals, and Packages Diverse Food Products

The GEA PowerPak series from GEA offers modular thermoforming packaging machines tailored for the food industry, excelling in precision, speed, and adaptability. Utilizing cutting-edge thermoforming techniques, these machines seamlessly process a variety of products, including meats, cheeses, seafood, and plant-based items, ensuring reliable packaging in MAP, vacuum, or skin packs. With processing capacities handling continuous high-speed outputs, these machines integrate PLC control systems for comprehensive automation and remote monitoring. The robust design, featuring stainless steel options, supports corrosion resistance and meets EU and US safety standards, including GMP and CE certifications. Available in customizable configurations—like the PowerPak 460, 560, 700, 420S, and 420X—these machines offer effortless integration into existing lines with minimal downtime and maintenance thanks to CIP systems.

Benefits

- Ensures versatile production capabilities, adapting quickly to diverse food product lines.

- Reduces material waste through precise sealing and cutting techniques.

- Minimizes energy usage with efficient servo motor technology.

- Facilitates seamless production integration with customizable modular design.

- Enhances operational uptime with robust construction and low-maintenance components.

- Applications

- Meat products, Fruits and vegetables, Cheese, Vegan products, Vegetarian products, Fish and seafood, Bakery products, Dairy products

- End products

- Cheddar cheese slices, Salmon fillets, Cherry tomatoes packs, Vegan cheese slices, Mixed salad trays, Spinach pies, Plant-based burger patties, Cold cuts, Yogurt cups, Croissants, Shrimp packs, Sandwich bread, Sausages, Sliced ham, Tofu blocks

- Steps before

- Slicing, Cutting, Portioning, Food Preparation

- Steps after

- Labeling, Quality Control, Lane Converging, Sorting, Rejection, Inspection

- Input ingredients

- meat, processed meat products, sausages, cold cuts, cheese, dairy products, fish, seafood, vegetarian products, vegan products, fruits, vegetables, pastries, baked goods

- Output ingredients

- vacuum packs, Modified Atmosphere Packs (MAP), skin packs, shrink packs, re-closable packs, zipper packs, top forming packs, environmentally-friendly packs, GEA FoodTray, mono-plastic material packs

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Machine Width

- 420 mm, 460 mm, 560 mm, 700 mm

- Film Width

- 240-700 mm

- Max. Index Length

- 400-800 mm

- Max. Draw Depth

- 130-190 mm

- Max. Frame Length

- 6000-20000 mm

- Max. Thickness Flexible Films

- 280 µm

- Max. Thickness Rigid Films

- 500-850 µm

- Machine Speed

- Speed up to 250 packages per minute (with PowerGuide and EasyGuide systems)

- Heating System

- PowerHeat Z and PowerHeat M

- Package Type

- Vacuum, MAP, Skin, Shrink, Re-closable

- Integration Capability

- Works with GEA and non-GEA systems

- Sealing Technique

- Tight seals for MAP, skin, and vacuum packs

- Servo Drives Option

- Available for lifting, cutting, punching systems

- Automation level

- Manual / PLC / SCADA

- Changeover time

- Fast changeover

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- High efficiency

- Compact footprint

- Designed for space-saving

- Packaging type

- MAP / Skin / Vacuum / Shrink / Re-closable / Environmentally-friendly

- Product type

- Meat / Cheese / Fish / Seafood / Vegetarian / Vegan / Fruits / Vegetables / Dairy / Bakery

- Product size and shape

- Sliced / Whole pieces

- Substrate compatibility

- Film / Fiber-based / Mono-plastic materials

- Machine Width

- 420 mm, 460 mm, 560 mm, 700 mm

- Film Width

- 240 - 460 mm, 240 - 560 mm, 240 - 700 mm

- Max. Index Length

- 800 mm

- Max. Draw Depth

- 190 mm

- Max. Frame Length

- 20, 000 mm, 12, 000 mm, 6, 000 mm

- Max. Thickness Flexible Films

- 280 µm

- Max. Thickness Rigid Films

- 500 µm, 850 µm

- Machine Footprint

- Compact

- Control Panel Type

- PLC-controlled

- Package size adaptability

- Customizable to various sizes

- Sealing technique

- Modular

- Adjustable sealing techniques

- Heating system

- Variable

- Different bottom web types

- Cutting and punching system

- Adjustable length and crosswise

- Labeling integration

- Compatible with GEA labeling solutions

- Loading system

- Flexible

- Single,multiple lane,robot loading

- Transport system

- Powerful transport chain

- Servo drives

- Optional

- For lifting,cutting,or second web infeed

- System integration

- Seamless with GEA and non-GEA systems

- Machine configuration

- Modular

- Individually assembled

- Robot loading solutions

- Available options

- Quality control integration

- GEA OxyCheck, LeakCheck integration

- Optional add-ons

- Wide range available for system enhancement