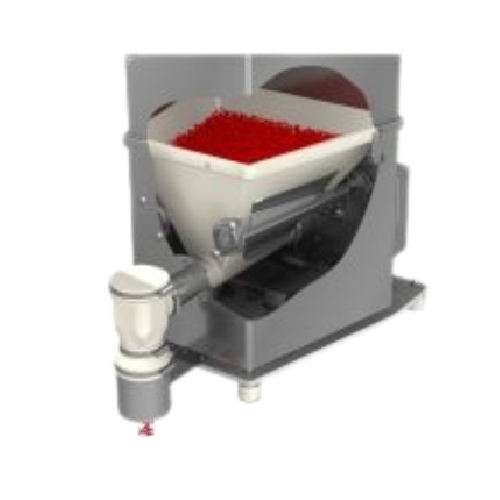

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line with a versatile volumetric feeder designed to handle a variety of materials without degradation, ensuring high-quality end products across diverse applications.

Achieves Consistent Ingredient Feeding and Mixing

The FlexWall®Plus Volumetric Feeder from SPS | Solids Process Solutions offers a dynamic solution for handling flowable ingredients such as powders, pellets, and granules across various industries, including aquafeed, pharmaceuticals, and recycling. Equipped with a flexible polyurethane hopper and amplitude adjustable paddles, it ensures consistent mass flow and screw filling without degrading the ingredients. Its compact trapezoidal shape allows efficient arrangement of up to six feeders around a central feed point. The feeder allows for effortless integration into your existing production line with interchangeable screws and screw tubes that facilitate quick adjustments to varying ingredients and feed rates.

Designed for continuous and automated operations, it offers optional features like a hinged motor for simple screw removal and a separate paddle motor to adjust paddle speed for challenging ingredients. With a focus on hygienic processing, its easy-clean design supports swift maintenance and extended durability. Available with customization support, the FlexWall®Plus caters to industry-specific needs, ensuring reliable feeding solutions tailored for specific production demands.

Benefits

- Enhances production flexibility with quick adjustment to ingredient changes.

- Facilitates optimal ingredient flow, minimizing wastage and ensuring product integrity.

- Compact design maximizes space efficiency in crowded production environments.

- Simplifies maintenance and reduces downtime with easy-clean features.

- Tailors to challenging ingredients with adjustable paddle speed, improving process reliability.

- Applications

- Food, Fine chemical, Feed, Recycling, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Silicone compounds, Laundry detergent powder, Color masterbatches, Aspirin tablets, Calcium carbonate, Fish pellets, Recycled plastic pellets, Snack seasonings, Protein supplements, Pvc compounds, Cheese powder, Vitamin premixes, Polypropylene beads, Dried pet food kibbles

- Steps before

- Mixing, Grinding, Blending, Heating

- Steps after

- Bagging, Bottling, Pelletizing, Packing

- Input ingredients

- powders, pellets, flakes, fibers, flowable ingredients

- Output ingredients

- consistent screw filling, mass flow of ingredient

- Market info

- Feed type

- Powder / Pellets / Flakes / Fibers

- Screw filling

- Consistent mass flow

- Hopper material

- Flexible polyurethane

- Adjustability

- Amplitude adjustable paddles

- Capacity

- Up to 6 feeders around a central feed point

- Screw interchangeability

- Quick adjustment for ingredients and feed rates

- Cleaning ease

- Easy and quickly cleanable

- Motor options

- Optional hinged motor for rear screw removal

- Paddle speed adjustment

- Optional separate paddle motor

- Working mechanism

- Volumetric feeder

- Batch vs. continuous operation

- Continuous

- Adjustable parameters

- Paddle amplitude, motor speed

- Feed material types

- Powders, pellets, flakes, fibers

- Cleaning method

- Easy and quick cleaning

- Paddle agitation

- Amplitude adjustable

- Interchangeable components

- Screws and screw tubes

- Compact design

- Trapezoidal shape for compact arrangement

- Cleanability

- Easy and quickly cleanable

- Abrasion Resistance

- Flexible polyurethane hopper

- Density/particle size

- Compatible with powders, pellets, flakes, fibers

- Corrosive resistance

- Polyurethane material

- Compact footprint

- Trapezoidal shape for compact arrangement

- Hopper material

- Flexible polyurethane

- Feed arrangement

- Up to 6 feeders around a central feed point

- Discharge method

- Screw discharge

- Interchangeable screws and screw tubes

- Yes

- Hinged motor

- Optional

- Separate paddle motor for speed adjustment

- Optional