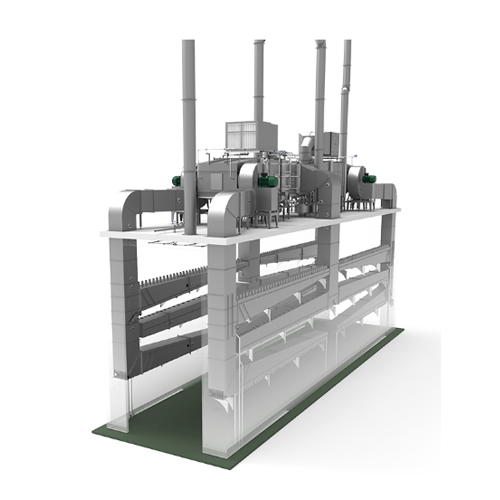

High-capacity industrial smoking and drying system

Maximize your production volume without expanding your facility footprint. Integrate high-capacity smoking, drying, and fermentation processes seamlessly within your existing setup, enhancing throughput for meats, fish, and dairy with advanced air and climate control.

Processes Meat, Fish, and Dairy for Optimal Yield

The Climamat Highcube by VETEC Anlagenbau is a versatile chamber designed for smoking, drying, and fermenting applications in meat, fish, and dairy production. This ETO equipment enhances production efficiency by employing a patented alternating treatment system that evenly processes both the top and bottom sections, ensuring uniform product quality. It supports a wide range of end-products, including frankfurters, salami, and cheddar cheese, with a scalable design that accommodates production volumes up to threefold. Its fully automatic operation, integrated with automated guided vehicles (AGVs), reduces labor costs while enabling seamless batch processing. Climate control is achieved using adaptable cooling and heating systems, compatible with glycol, freon, or ammonia for cooling, and hot water, steam, or electric options for heating. The machine’s design includes a CIP system for streamlined, high-standard hygiene maintenance. Every unit can be customized with advanced options such as smoke generators and a central management system for detailed process oversight, fulfilling the needs of food industry leaders.

Benefits

- Increases production volume efficiently with high-capacity, space-saving design.

- Ensures consistent product quality through uniform air distribution and precise climate control.

- Minimizes labor requirements with fully automatic operation and AGV integration.

- Enhances hygiene and safety with a fully automatic CIP system.

- Offers flexible operation, supporting multiple processes—smoking, drying, and fermentation—in one unit.

- Applications

- Cooked sausage, Pet food, Cheese, Thawed products, Boiled sausage, Raw sausage, Cured meat products, Fish

- End products

- Bologna, Thawed chicken fillets, Kibble, Frankfurters, Prosciutto, Smoked salmon, Salami, Cheddar cheese

- Steps before

- Curing, Fermentation, Preparation, Salting

- Steps after

- Cooling, Pasteurising, Packing, Storage

- Input ingredients

- raw sausage, cured meat products, boiled sausage, cooked sausage, fish, pet food, cheese, thawed products

- Output ingredients

- air-dried meat, salami products, smoked products, cured products, dried products

- Market info

- Vetec is known for its expertise in manufacturing customized industrial valves and actuators, catering to diverse industries with a reputation for reliability, precision engineering, and innovative solutions tailored to specific customer requirements.

- Rack height

- Up to 7m / 23 ft.

- Automation

- Full automation loading and unloading system

- Air flow

- Very efficient air flow

- Production time

- Short batch times

- Capacity

- Higher product capacity

- Cooling medium

- Glycol, Freon, Ammonia

- Heating type

- Hot water, Steam, Electric

- PH value control

- Automatic pH value changeover

- Cleaning system

- Fully automatic CIP-System

- Cleaning method

- CIP with rotating nozzles

- Automation level

- Fully Automatic

- Batch vs. continuous operation

- Batch

- CIP System

- Fully Automatic

- Flexibility

- High Flexibility

- Product Quality

- Outstanding

- Process Uniformity

- Absolute Uniformity

- Corrosive resistance (e.g. acids)

- High resistance required

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- System height

- Up to 7m / 23 ft.

- Loading/Unloading System

- Full automation available

- Rack type

- Extra high racks

- Automation of loading and unloading

- Fully automatic

- Rack Height

- Up to 7m / 23 ft.

- Transportation system

- Full automation

- Smoke generator type

- Glowing smoke / Liquid smoke / Friction smoke systems

- CIP system

- Fully automatic with rotating nozzles

- Cooling media options

- Glycol / Freon / Ammonia

- Heating options

- Hot water / Steam / Electric

- Control and documentation system

- MICROMAT ANALYZER