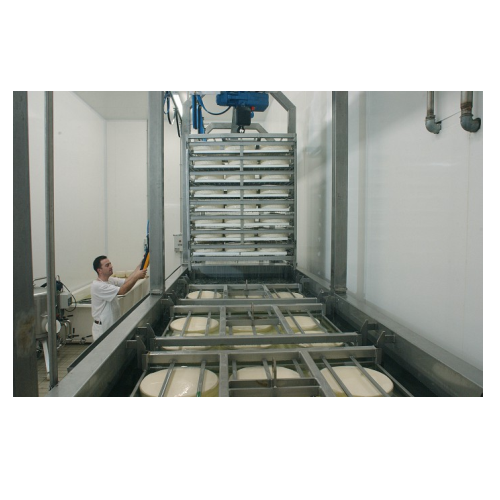

Dynamic salting system for cheese production

Ensure even and efficient salting for soft and semi-hard cheeses with a dynamic system that optimizes the brining process through controlled immersion and circulation.

Immerses and Circulates Cheese in Brine

The Dynamic Cheese Salting System by Priamo Food Technologies is engineered to optimize cheese salting through a fully automated brine immersion process. This system features a centrifugal electric pump that ensures consistent brine circulation and stirring, crucial for uniform salting across diverse cheese types such as Taleggio, Gorgonzola, and Feta. Its automated transporting and lifting system positions cheese forms with precision, enhancing workflow efficiency in dairy processing environments. Designed for continuous operation, it seamlessly integrates into existing production lines, reducing manual labor and improving throughput. Constructed from high-grade stainless steel, the system offers superior corrosion resistance and compatibility with stringent hygiene standards. Tailored to your facility’s unique requirements, Priamo provides engineering support and customizable options to meet specific production demands.

Benefits

- Ensures consistent salinity levels across cheese batches, enhancing product quality.

- Streamlines operations with fully automated immersion and lifting, reducing manual intervention.

- Integrates smoothly into existing lines for continuous, uninterrupted production.

- Constructed for high resistance to corrosion, ensuring longevity and hygiene compliance.

- Customizable configurations adapt to specific production needs, optimizing facility efficiency.

- Applications

- Dairy products, Cheese

- End products

- Feta cheese, Gorgonzola cheese, Taleggio cheese, Crescenza cheese, Ricotta cheese, White cheese

- Steps before

- Coagulation, Curd Draining, Curd Portioning

- Steps after

- Ripening, Aging, Packaging

- Input ingredients

- cheese forms, sodium chloride solution, brine

- Output ingredients

- salted cheese

- Market info

- Priamo (Omnia Technologies) is known for manufacturing custom-engineered, high-quality processing equipment for the dairy, beverage, and food industries, praised for their innovative solutions, reliable performance, and commitment to meeting specific client requirements in industrial equipment.

- Material

- AIS 316L stainless steel

- Brine Circulation

- Centrifugal electric pump

- Automation

- Automated transporting and lifting system

- Customization

- Made to measure

- Working mechanism

- Centrifugal electric pump for stirring and circulation

- Batch vs. continuous operation

- Batch

- Automation level

- Automated transporting and lifting system

- Integration of steps

- Immersion salting process with cage system

- Brine control

- Constant stirring and circulation

- Biological compatibility

- Yes

- Cleanability

- High, due to stainless steel 316L

- Corrosive resistance

- Suitable for contact with sodium chloride solution (brine)

- Cheese type compatibility

- Various forms of cheese

- Cheese form handling

- Cages for cheese placement

- Cheese processing step

- Final salting

- Material of Construction

- AIS 316L stainless steel

- Tank size

- Custom sizes

- Footprint

- Made to measure

- Immersion method

- Automated transporting and lifting system

- Pump type

- Centrifugal electric pump

- Basket type

- Cheese forms cage

- Cage Dimensions

- Customizable

- Automated Transport and Lifting System

- Yes

- Material Construction

- Stainless Steel (AIS 316L)