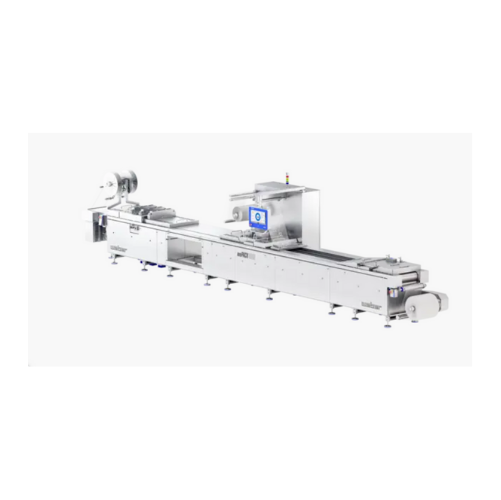

Thermoforming packaging solution for medium production volumes

Optimize your medium-volume packing with a compact thermoforming machine designed for efficiency and sustainability, reducing film waste through advanced gas flushing while seamlessly integrating into existing production lines for continuous, high-speed operations.

Packages and Seals Diverse Food Products

The Weber wePACK 4000 is a modular thermoforming packaging machine designed to accommodate medium production volumes of up to 100 packages per minute. This equipment is specially suited for a wide array of food products, including cheese, deli meats, and ready meals, offering flexibility in Modified Atmosphere Packaging (MAP), vacuum, and skinning applications. What sets the wePACK 4000 apart is its integration of a special gas flushing system that significantly reduces material waste by cutting bottom film trim by approximately 50% and eliminating top film trim. The wePACK 4000 employs servo technology for its main transport chain, promoting sustainability and maintaining precise control. It can be seamlessly integrated into existing Weber line solutions, benefiting from common control and operating technologies across to simplify operations. With a customizable machine length, variable film widths, and a wide range of film material options, it meets diverse packaging needs. This machine not only ensures energy efficiency but also supports sustainability with its compatibility with Weber PaperTech for fiber-based films, ensuring high-quality packaging that preserves product integrity.

Benefits

- Reduces material waste by up to 50% with efficient gas flushing system.

- Enhances product shelf life with reliable Modified Atmosphere Packaging.

- Increases production efficiency with a capacity of up to 100 packages per minute.

- Eases maintenance with accessible design for quick serviceability.

- Offers sustainable packaging solutions through compatibility with fiber-based films.

- Applications

- Snacks, Bakery, Vegetarian, Cheese, Whole muscle, Cooked ham, Vegan, Bacon, Fish, Convenience foods, Sandwich, Raw sausage, Fresh meat, Deli, Pet food, Dried sausage, Raw ham, Ready meal, Raw/smoked ham, Veggie

- End products

- Cheddar cheese slices, Vegan cheese, Club sandwich, Potato chips, Smoked bacon strips, Salmon fillets, Microwaveable mac and cheese, Tofu patties, Dry dog food, Ground beef patties, Croissants, Bratwurst links, Veggie burgers, Frozen lasagna, Honey-glazed ham slices, Smoked salmon, Salami sticks, Plant-based sausages, Beef steaks, Prosciutto, Deli turkey breast

- Steps before

- Slicing, Loading, Gas flushing

- Steps after

- Labeling, Sorting, End-of-Line handling

- Input ingredients

- raw ham, bacon, deli, cooked ham, raw sausage, cheese, snacks, convenience foods, veggie, vegan, fiber-based films, bottom film, top film

- Output ingredients

- MAP packages, vacuum packages, standard skinning packages, medium production volume packages, up to 100 packages per minute

- Market info

- Weber Maschinenbau Germany is renowned for its innovative solutions in the food processing industry, specializing in industrial slicing machines and equipment for high-quality meat and cheese processing, offering precision and efficiency to leading global manufacturers.

- Production Speed

- up to 100 packages per minute

- Cycle Speed

- approx. 5-15 cycles/min

- Bottom Film Width

- 280 - 560 mm, in 10 mm steps

- Top Film Width

- up to 560 mm

- Max Index Length

- up to 650 mm

- Max Pack Depth

- up to 120 mm / 150 mm

- Film Material Thickness

- up to 600 mic

- Top Film Reel Max Diameter

- 1x or 2x 400mm

- 1x 500 mm

- Bottom Film Reel Max Diameter

- 1x or 2x 400 mm

- 1x 500 mm

- 1x 800 mm jumbo

- Reel Core Diameter

- 3" or 6" cores

- Machine Width

- up to 1200mm

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick changeover

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Cycle speed

- 5–15 cycles/min

- Energy efficiency

- High

- Integration capability

- Weber line solutions

- Operating speed

- Up to 100 packages/min

- Sustainability

- Resource-saving, waste reduction

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine length

- Modular

- Customized

- Machine width

- Up to 1200 mm

- Loading area

- Customized

- Loading area knee free

- Upon Request

- Bottom film width

- 280 - 560 mm, in 10 mm steps

- Top film width

- Up to 560 mm

- Max. index length

- Up to 650 mm

- Max. pack depth

- Up to 120 mm / 150 mm

- Tool top lift forming / sealing

- No / No

- Control panel type

- Common control technology for all Weber machines

- Integration possibilities

- Fully integratable with Weber line solutions

- Footprint

- Compact for medium production volumes

- Modular Design

- Customizable machine length