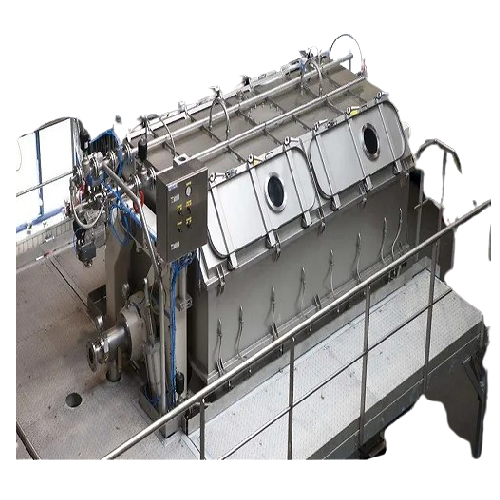

Solidification drum for chemical and pharmaceutical products

Convert molten materials into easily manageable flakes efficiently with this versatile drum flaker, ideally suited for processing heat-sensitive or volatile compounds.

Solidifies and Flakes Molten Products Efficiently

The ANDRITZ Gouda Drum Flaker is engineered to transform molten substances into solid flakes through its efficient cooling drum mechanism. Particularly effective for chemical, pharmaceutical, and food industries, this equipment is indispensable for applications requiring solidification and flaking of products such as soaps, resins, and chocolate.

Its continuous process operation involves a rotating, internally cooled drum where a thin molten layer adheres, solidifies, and is subsequently scraped off by a precision knife, resulting in consistent flake size and quality. The flaker integrates seamlessly into production lines with options for a dip feed or an overhead applicator roll, adapting to various product viscosities and adhesion properties.

With a dust and gas-tight design, it supports safe operation of toxic or odorous materials, while offering significant energy savings through optimized coolant circulation. Constructed with robust materials like stainless steel or Hastelloy, the flaker is durable and corrosion-resistant, accommodating stringent chemical processing needs. Customizations are available for scraper systems and drum materials to suit specific processing requirements.

Benefits

- Enhances efficiency with continuous operation and precise flake size control.

- Reduces energy costs through optimized coolant circulation.

- Ensures safe handling of volatile products with a dust and gas-tight design.

- Adapts to various product types with customizable scraper and drum options.

- Offers corrosion resistance suitable for aggressive chemical processing environments.

- Applications

- Chemicals, Food, Stearates, Dough, Oleochemicals, Cheese, Soap, Fatty acids, Vegetables, Resins, Chocolate, Pharmaceuticals

- End products

- Calcium chloride flakes, Wax pastilles, Emulsifiers, Synthetic resins, Flake soaps, Surfactants, Dough flakes, Chocolate flakes, Vegetable flakes, Catalysts, Cheese flakes

- Steps before

- Melting, Heating, Mixing

- Steps after

- Cooling, Scraping, Comminution, Packing

- Input ingredients

- molten chemicals, pharmaceutical products, toxic materials, offensively smelling products, molten food ingredients, molten fatty acids, oleochemicals, phthalic anhydride, PEG, maleic anhydride, calcium chloride, caprolactam, resins, bisphenol A, sulphur, stearate, soap, molten cheese, molten chocolate, dough, vegetables

- Output ingredients

- solidified chemicals, solidified pharmaceutical products, flakes, easily manageable pastilles, flakes of fatty acids, solidified oleochemicals, flakes of phthalic anhydride, solidified PEG, flakes of maleic anhydride, solidified calcium chloride, flakes of caprolactam, resin flakes, solidified bisphenol A, flakes of sulphur, stearate flakes, soap flakes, solidified cheese, solidified chocolate, dough flakes, vegetable flakes

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Drum Size

- Varies, typically up to several meters in diameter

- Material Compatibility

- Stainless steel, chrome plated, Hastelloy, cast iron

- Coolant circulation

- Internally cooled drum

- Product Type

- Flakes, pastilles

- Process Type

- Continuous

- Heating/Cooling Medium

- Internal cooling

- Scraper Type

- Knife scraper adjustable by pneumatic pressing system

- Flake Thickness Control

- Precisely controlled via system adjustments

- Design Type

- Closed design

- Applicator Roll Type

- Dip pan or overhead applicator roll

- Working mechanism

- Flaking via cooling drum

- Integrated steps

- Continuous solidification

- Batch vs. continuous operation

- Continuous

- Product removal

- Knife scraper

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Knife scraper

- Cooling method

- Internally cooled drum

- Drum material

- Stainless steel, chrome plated, Hastelloy or cast iron

- Drum Material

- Stainless Steel / Chrome Plated / Hastelloy / Cast Iron

- Scraper Material

- Steel / Plastics

- Scraper Pressure Adjustment

- Pneumatic Pressing System

- Drum Groove Design

- Dovetail-sectioned Grooves

- Cooling System

- Internally Cooled Drum

- Feeding System

- Dip Feed / Overhead Applicator Roll

- Control System

- Metris addIQ Control Systems