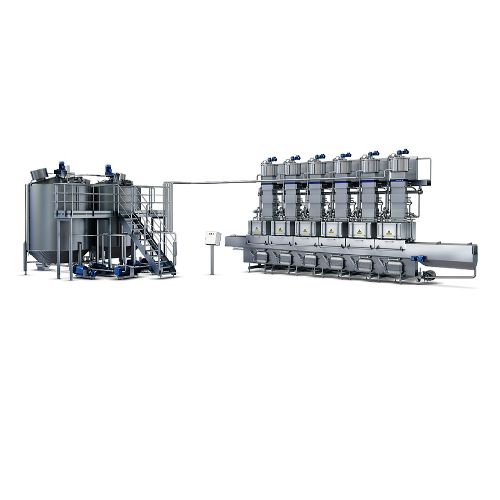

Continuous cheese and whey production system

Streamline your cheese production process with a system that handles whey drainage, pre-pressing, and mould filling efficiently, ensuring accurate cheese block formation and quality whey output, all while minimizing weight and moisture variations for consistently high-quality results.

Drains, Pre-presses, and Mould Fills Cheese Blocks

The Tetra Pak Casomatic system SC7 is a fully automatic solution engineered for seamless integration into dairy and cheese production lines. This system is optimized for the efficient processing of cheese varieties such as Gouda, Edam, and Maasdam, enhancing your operation’s capacity to produce consistent and high-quality cheese blocks or wheels. Among its many features, the SC7 utilizes a flexible whey drainage system, ensuring precise whey removal crucial for maintaining consistent moisture and weight across cheese batches.

With its continuous operation capabilities, the SC7 handles medium to high volumes, making it ideal for large-scale production facilities. Its automation is controlled by advanced software that monitors and adjusts processes in real-time, mitigating production disruptions. The system is constructed from high-grade stainless steel, ensuring durability and meeting stringent hygiene standards mandatory in food processing.

Incorporating a unique dimple jacket cooling feature, the SC7 limits acidification and moisture variability, improving cheese uniformity while its CIP system facilitates rapid, thorough cleaning to minimize downtime. Furthermore, Tetra Pak offers engineering support to modify specific components to fit your unique production requirements, making the SC7 a customizable and robust addition to any cheese manufacturing line.

Benefits

- Ensures consistent cheese quality by maintaining precise moisture and weight control.

- Enhances production efficiency with continuous, automated operation, reducing manual intervention.

- Minimizes cleaning time with CIP system, increasing production uptime.

- Reduces energy usage and acidification variability through optimized cooling technology.

- Customizable design adapts to specific production requirements, supporting diverse cheese types.

- Applications

- Edam, Maasdam, Cheese, Semi-hard cheese, Gouda, Whey, Granular cheese, Hard cheese, Dairy

- End products

- Emmental cheese, Semi-hard cheese slabs, Havarti cheese, Gruyère cheese, Edam rounds, Gouda cheese wheels, Parmesan wheels, Romano cheese, Granular cheese curd, Provolone logs, Whey protein concentrate, Maasdam blocks, Swiss cheese blocks, Ricotta cheese, Grana padano, Cheddar cheese blocks, Hard cheese slices

- Steps before

- Milk Reception, Curdling, Curd Cutting

- Steps after

- Cheese Pressing, Cheese Ripening, Packaging

- Input ingredients

- curd, whey

- Output ingredients

- cheese, whey

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- High capacity per column

- Automation

- Fully automatic

- Drainage system

- Flexible whey drainage system

- Cooling feature

- Dimple jacket cooling

- Whey circulation

- Continuous whey circulation system

- Moisture variation control

- Reduces variations in moisture content

- Weight accuracy

- Outstanding weight accuracy

- Block formation

- Accurate cheese block formation

- Environmental performance

- Improved environmental performance

- Cooling medium

- Curd/whey mixture cooling

- Process control

- Advanced control software

- Conveyor handling

- Gentle handling

- Working Mechanism

- Continuous inline process

- Integrated Steps

- Whey drainage, pre-pressing, cheese block formation, mould filling

- CIP/SIP

- Automatic CIP for hygiene

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- Fully automated with advanced control software

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Tank shape

- Conical

- Feed method

- Automatic continuous

- Discharge method

- Automatic mould filling

- Column count

- 6 columns

- Control panel type

- Advanced HMI with touch screen

- Integration possibilities

- Compatible with existing plant automation systems

- Modularity

- Expandable with additional columns

- Cooling system customization

- Option for dimple jacket cooling

- Drainage system configuration

- Customizable perforated sections