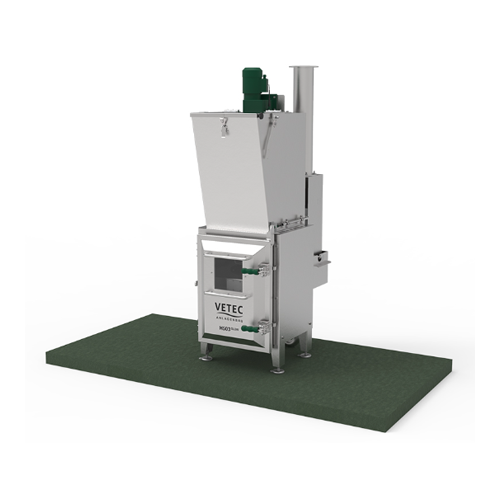

Closed glow smoke generator for hot smoking installations

Enhance your smoking process with efficient energy use and seamless integration—ideal for producing tender, flavor-infused foods with consistent smoke quality.

Generates Smoke and Conditions Climate for Food Processing

The H503 Glow from VETEC Anlagenbau is engineered to provide consistent and efficient smoke generation and climate conditioning for a variety of food processing applications. It employs a closed system using natural wood chips, ensuring uniform smoke distribution without external leakage, which enhances product quality and safety. Capable of processing up to 12 trolleys in hot smoking installations and up to 80 trolleys in climate maturing systems, it excels in producing end-products such as frankfurters, salami, and smoked salmon.

The equipment is set apart by its energy efficiency, achieving up to 30% energy savings with shorter heat-up and smoking cycles. Automation is enhanced through a user-friendly compact control unit, offering individual adaptation of smoke density and ensuring operational continuity with a front chip level display that reduces downtime. Safety is paramount, with integrated temperature monitoring and a water pressure control system that ensures a reproducible production process. The absence of water consumption in smoking mode further contributes to energy savings and environmental sustainability.

Available in robust material options, the H503 Glow is suitable for rigorous industrial environments, serving industries from meat and fish processing to dairy and pet food production. It supports batch and continuous operations, integrating seamlessly with existing production lines, and VETEC offers customization and engineering support to tailor the solution to specific processing needs.

Benefits

- Enhances operational efficiency with up to 30% energy savings.

- Minimizes downtime through a user-friendly control interface and real-time monitoring.

- Ensures consistent product quality with uniform smoke distribution and climate control.

- Supports environmental sustainability with zero water consumption during smoking.

- Provides reliable safety with integrated temperature and pressure controls.

- Applications

- Cooked sausage, Pet food, Cheese, Thawed products, Boiled sausage, Raw sausage, Cured meat products, Fish

- End products

- Dog kibble, Bologna, Gouda cheese, Frankfurters, Defrosted chicken breast, Prosciutto, Smoked salmon, Salami

- Steps before

- Thawing, Fermentation, Pasteurizing

- Steps after

- Cooling, Baking, Drying

- Input ingredients

- natural wood chips

- Output ingredients

- hot smoking installations, climate maturing systems, uniform smoke development, energy savings products, delicate casing products

- Market info

- Vetec is known for its expertise in manufacturing customized industrial valves and actuators, catering to diverse industries with a reputation for reliability, precision engineering, and innovative solutions tailored to specific customer requirements.

- Smoke generator capacity

- Up to 12 trolleys (smoking)

- Up to 80 trolleys (climate maturing)

- Smoking material

- Natural wood chips

- Energy savings

- Up to 30%

- Heat-up time

- Shorter due to higher smoke concentration

- Safety features

- Temperature monitoring with integrated extinguishing device and water pressure control

- Control unit

- User-friendly compact control unit

- Water consumption

- No water consumption in smoking mode

- Smoke moisture

- Moist smoke in closed system

- Front chip level display

- Prevents downtimes

- Working Mechanism

- Closed glow smoke generator

- Integrated Steps

- Temperature monitoring with extinguishing device

- Batch vs. Continuous Operation

- Batch operation

- Energy Efficiency

- Saves up to 30% energy

- Automation Level

- User-friendly compact control unit

- Chip Level Monitoring

- Front chip level display

- Smoke Development Control

- Uniform and constant smoke development

- Casing Delicateness

- Moist smoke in closed system

- Abrasion resistance

- Durable against abrasion due to robust construction

- Biological compatibility

- Safe for food contact surfaces

- Cleanability

- Easy to clean and maintain, suitable for food industry standards

- Corrosive resistance (e.g. acids)

- Resistant to smoke and moisture-related corrosion

- Smoke generator type

- Closed glow

- Smoking capacity

- Up to 12 trolleys

- Climate maturing systems capacity

- Up to 80 trolleys

- Feed method

- Natural wood chips

- Control panel type

- User-friendly compact control unit

- Smoke density adaptation

- Individual adaptation possible

- Front chip level display

- Prevents downtimes

- Integration possibilities

- Temperature monitoring with integrated extinguishing device

- Water usage

- No water consumption in smoking mode