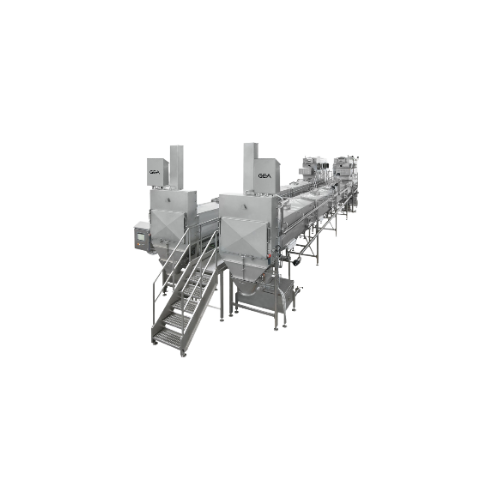

Continuous curd drainage and maturation systems for pasta filata cheese

Enhance your cheese production by optimizing curd drainage and maturation with advanced tunnel systems, reducing processing time and ensuring precise control over curd characteristics for consistent, high-quality pasta filata cheese.

Drains, Matures, and Transports Curd for Cheese Production

The GEA Continuous Curd Drainage and Maturation Tunnel Systems provide an efficient solution for pasta filata cheese production, including mozzarella and provolone. Featuring a rotating drainage drum and inclined maturation tunnels, the system optimizes curd drainage and maturation through precisely controlled auger speed and whey removal. Capacities range from 6,000 to 8,000 kg/h, catering to significant production demands. Built from AISI 304 stainless steel, it ensures hygiene and corrosion resistance, accommodating automatic cleaning-in-place (CIP) systems that reduce water usage and downtime. With PLC control for enhanced automation, it integrates easily into existing production lines, while double-walled jackets offer accurate temperature control during maturation. Customization options are available to fit specific plant layouts and utility requirements, ensuring optimal configuration for diverse cheese manufacturing operations.

Benefits

- Increases production efficiency with continuous, automated curd processing.

- Optimizes curd quality through precise control over maturation and drainage.

- Reduces operational costs with integrated cleaning-in-place and minimized manual intervention.

- Enhances safety with built-in mechanical barriers and safety switches.

- Adapts to plant specifications with customizable configurations for space and utility compatibility.

- Applications

- Pasta filata cheese, Dairy products

- End products

- Burrata, Mozzarella, Caciocavallo, Provolone, Stracciatella, Scamorza

- Steps before

- Curd formation, Curd transfer

- Steps after

- Stretching, Cheese shaping, Packaging

- Input ingredients

- curd, whey

- Output ingredients

- pasta filata cheese, customized curd sizes, drained whey

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 6, 000-8, 000 kg/h

- Material

- AISI 304 stainless steel

- Automation

- PLC-controlled

- Auger speed control

- Electronically-controlled with inverter and sensor

- Maturation time control

- Electronically-controlled

- Cycle heating

- Hot water heating with double-walled jackets

- Cooling system

- Piping system for product cooling

- Cleaning method

- Automatic cleaning-in-place

- Cutting method

- Guillotine cutting

- Transport method

- Rotary auger

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Automatic cleaning-in-place

- Cleaning method

- CIP

- Changeover time

- Minimal due to automation

- Cleanability

- Hygienic design for easy cleaning

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Discharge method

- Rotating drainage drum

- Inclined tunnel design

- Partial maturation with whey

- Guillotine cutting size

- Customizable

- Material

- AISI 304 stainless steel

- Cleaning-in-place system

- Automated

- Safety features

- Mechanical barriers, proximity switches, and safety switches

- Custom plant fitment

- Configurable to fit layout and footprint