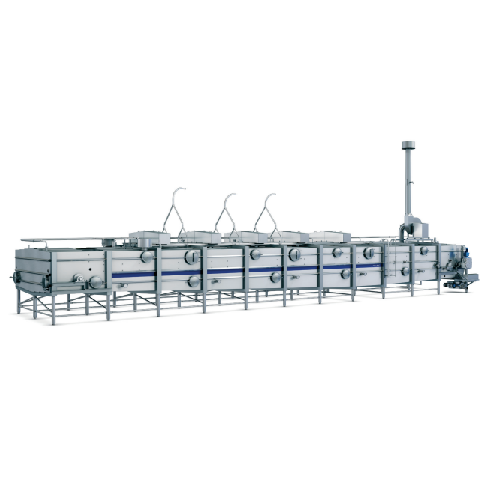

Salting mellowing conveyor for cheese curd

Achieve optimal salt distribution and retention in your cheese production with a solution designed to enhance flavor consistency, reduce waste, and streamline your salting and mellowing processes.

Uniformly Salts and Mellow Cheese Curds

The Tetra Pak® Salting Mellowing Conveyor 2 is engineered to enhance the cheese processing line by seamlessly integrating salting and mellowing processes. Designed by Tetra Pak, this machine effectively addresses the challenge of achieving optimal salt retention in cheese curds, ensuring consistent product quality across a broad range of cheese types, including mozzarella, cheddar, and gouda. The conveyor operates continuously, capable of handling capacities up to 16,300 kg/hr (36,000 lbs/hr), making it suitable for high-volume cheese manufacturers and dairy producers.

Utilizing application-specific agitators, the machine gently stirs the curd to ensure uniform salt distribution and effective whey drainage, extending absorption times and minimizing cheese fines. The pairing with the Tetra Pak® Salt-Dispenser 2 allows precise salt application through controlled airflow and specialized nozzles, reducing salt usage and enhancing retention.

Constructed from durable, corrosion-resistant materials, the conveyor is built to withstand the harsh environments created by salty cheese and whey, guaranteeing a long operational life. It supports CIP (Clean-In-Place) isolation, enabling shorter cleaning times without halting production, thereby maximizing uptime and efficiency. Customization options allow for varying belt widths, lengths, speeds, and salt application ratios tailored to specific production needs.

Benefits

- Ensures consistent cheese quality with precise and even salt distribution.

- Increases production efficiency with continuous processing and high capacity throughput.

- Enhances product consistency and reduces waste thanks to optimal salt retention and minimal cheese fines.

- Lowers maintenance time and costs through CIP isolation, enabling fast and efficient cleaning.

- Provides long-term reliability and durability in corrosive environments due to high-quality, corrosion-resistant materials.

- Applications

- Cheddar, Cheese, Cheese curd, Semi-hard cheese, Dry-salted cheeses, Milled cheese, Granular cheese, Dairy

- End products

- Feta, Mozzarella, Havarti, Colby, Ricotta salata, Gouda, Asiago, Parmesan, Pecorino, Paneer, Monterey jack

- Steps before

- Cheese curd preparation, Cheese curd milling, Salt dispensing

- Steps after

- Cheese processing, CIP cleaning, Packaging

- Input ingredients

- cheese curd, salt

- Output ingredients

- salted cheese, whey

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- Up to 16300 kg/hr (36000 lbs/hr)

- Salt Application Method

- Controlled airflow with nozzles

- Belt Configuration

- Variable widths, lengths, speeds

- CIP Isolation

- Yes

- Operational Environment Compatibility

- Corrosive (salty cheese and whey)

- Working mechanism

- Continuous

- Integrated steps

- Salting and mellowing

- Automation level

- PLC

- CIP/SIP

- CIP enabled

- Cleaning method

- CIP

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Adjustable setups for different cheese recipes

- Cheese type applicability

- All cheese types

- Belt width

- Variable

- Belt length

- Variable

- Machine footprint

- Compact/Variable

- Control panel type

- PLC-controlled

- Discharge method

- Variable based on application

- Feed method

- In-line feeding

- Agitator type

- Application specific

- Belt Widths

- Variable

- Belt Lengths

- Variable

- Belt Speeds

- Variable

- Salt Application Ratio

- Adjustable

- CIP Isolation Device

- Available