Concentrate heater for dairy spray dryers

Achieve precise temperature control in dairy powder production with a concentrate heater that gently preheats liquid milk feeds, enhancing final product consistency and quality while optimizing spray dryer performance.

Preheats Concentrated Milk for Uniform Spray Drying

The GEA SaniX Concentrate Heater is engineered to preheat concentrated milk feed with precision before it reaches the spray dryer, ensuring uniform temperature for optimal spray drying results. Integrated into the GEA dairy spray dryer systems as standard, this equipment plays a critical role in maintaining the integrity and functionality of dairy and nutritional powders. It employs hot water heating, offering a cost-efficient and gentler approach compared to traditional steam systems, effectively reducing energy use.

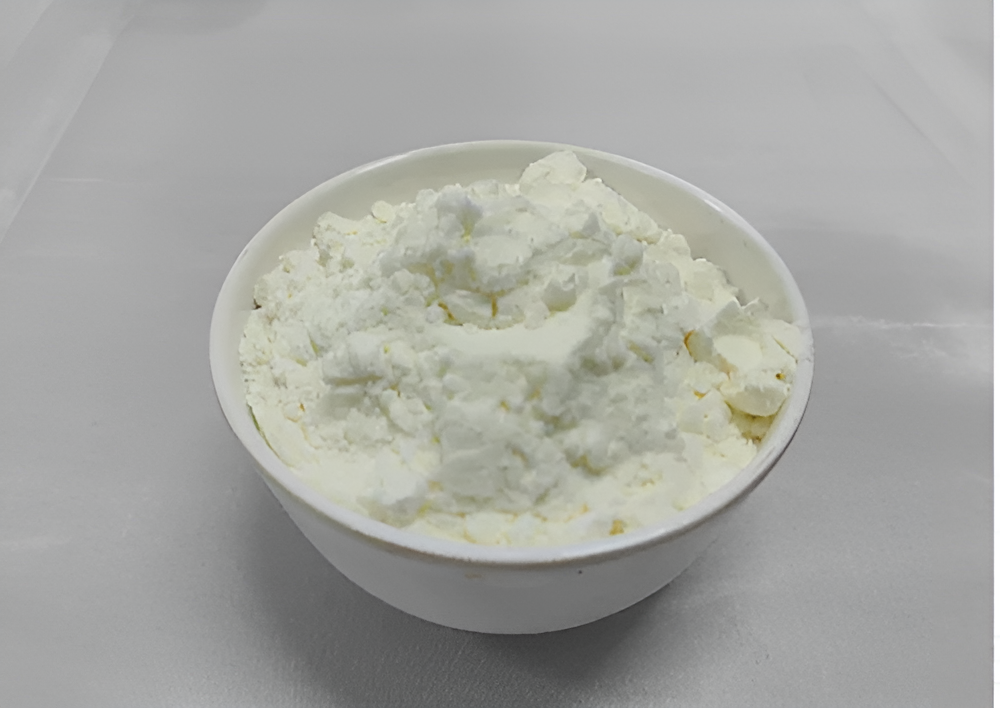

Suitable for the dairy and food industries, the SaniX Concentrate Heater is versatile, processing a range of end products such as whole milk powder and protein-fortified milk powder. Its spiral, dual-channel heat exchanger design ensures that the milk feed is evenly heated, safeguarding against protein denaturation and enhancing powder dispersibility.

This process is supported by a high heat transfer coefficient and turbulent flow, maintaining consistent temperature control. Fully compliant with EHEDG guidelines and available with USDA / 3A certification, the SaniX equipment is compatible with third-party systems and configurable to meet specific processing needs. Its design facilitates continuous operation and easy integration within existing production lines, supporting both efficiency and product quality.

Benefits

- Enhances product consistency by maintaining precise feed temperature, ensuring uniform powder quality.

- Lowers operational costs through efficient hot water heating, reducing energy consumption.

- Protects product integrity with gentle heating to prevent degradation of sensitive constituents.

- Compliant with EHEDG guidelines, offering reliable hygiene standards for food and dairy production.

- Seamlessly integrates with existing systems, supporting flexible and continuous operations.

- Applications

- Spray dried dairy products, Liquid milk, Whey powder, Food powders, Milk powders, Nutritional formulas, Dairy products, Dairy

- End products

- Skimmed milk powder, Protein-fortified milk powder, Coffee creamers, Whole milk powder, Infant formula, Instant milk drinks, Yogurt powder, Dairy-based nutritional supplements, Cheese powder, Whey protein powder

- Steps before

- Evaporation, Milk Concentration, Feed Preparation, Heat Treatment

- Steps after

- Spray Drying, Powder Handling, Packing

- Input ingredients

- concentrated milk feed, liquid milk, milk concentrate

- Output ingredients

- spray dried dairy powders, milk powder, final powder, reconstitutable powder

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Heater Type

- SaniX Concentrate Heater

- Heating Medium

- Hot Water

- Heat Exchange Coefficient

- Very High

- Temperature Control

- Optimized, Fine-tuned

- Temperature Uniformity

- Uniform Heating

- Spiral Design

- Yes

- Heating Channels

- Two Channels

- Automation

- PLC-controlled

- Working mechanism

- Heat exchange with hot water

- Integrated steps

- Preheating of milk concentrate

- Automation level

- PLC / SCADA

- CIP/SIP capability

- CIP 121°C / SIP 135°C

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Uses hot water to reduce costs

- Temperature control

- Precise, uniform heating

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- High

- Viscosity

- Variable

- Agglomeration Risk

- Moderate

- Foaming

- Low

- Compact footprint

- Yes

- Control panel type

- Touch screen

- Discharge method

- Uniform heating via heat exchanger