Autoclavable glass fermentor for biotech research

Optimize your fermentation processes with a versatile benchtop solution, designed to facilitate both batch and continuous operations—perfect for cultivating proteins, monoclonal antibodies, and more, while offering precise control and easy integration into your R&D workflows.

Cultivates and Ferments Cells and Microorganisms

BRS Biotech offers Autoclavable Glass Fermentors & Bioreactors, engineered to meet the precise demands of laboratory-scale fermentation and cultivation. These units are designed for biotech, pharmaceutical, and food industries, facilitating the cultivation and fermentation of microorganisms and cells crucial in biopharmaceuticals, fine chemicals, and nutraceuticals production. With volumes ranging from 1 to 10 liters, they support batch and continuous operations, allowing flexibility in research applications such as monoclonal antibodies or plant-based vaccines.

The fermentor is table-mounted for convenience and maintenance simplicity, featuring detached power source and control tools for easy customization and servicing. Key controls include temperature, pH, and dissolved oxygen, with advanced options for monitoring cell suspension concentrations and exhaust analysis. Made from durable 316L steel and borosilicate glass, these systems ensure chemical resistance and durability. They are compliant with industry standards and integrate smoothly into existing lab setups, providing a reliable solution for optimizing fermentation processes and novel product development.

Benefits

- Enhances research productivity with flexible batch and continuous operations.

- Streamlines process optimization through modular measurement and control systems.

- Minimizes contamination risk with autoclaving capability for sterilization.

- Supports diverse applications from insulin production to microalgae cultivation.

- Provides durability and resistance to corrosion with 316L steel and borosilicate glass construction.

- Applications

- Proteins, Fine chemicals, Nutraceuticals, Monoclonal antibodies, Microalgae cultivation, Biopharmaceuticals, Fermentation processes, Plant and animal cell cultivation

- End products

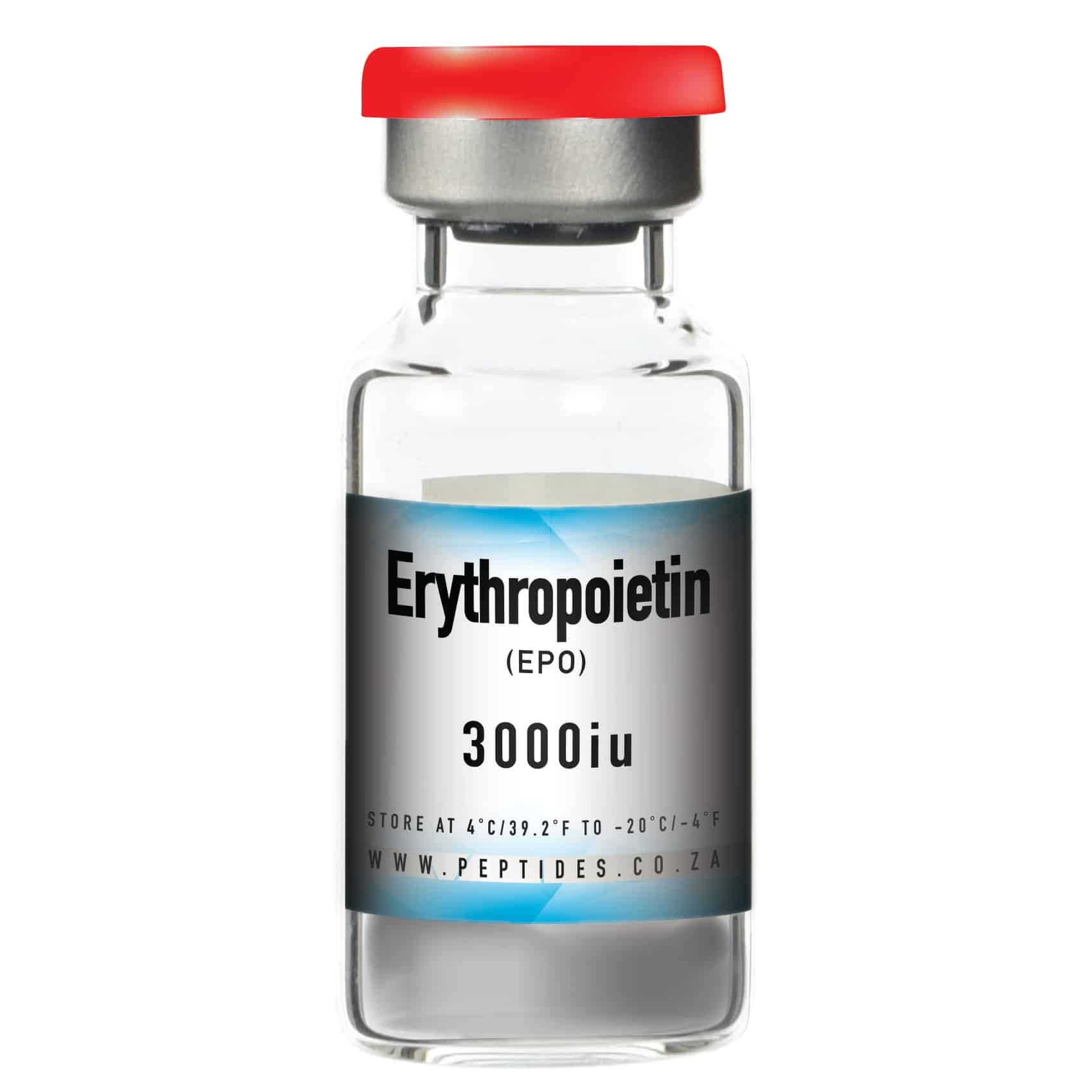

- Amino acids, Chlorella powder, Citric acid, Erythropoietin, Plant-based vaccines, Insulin, Spirulina tablets, Ethanol, Cultured meat, Omega-3 supplements, Vitamin b12 supplements, Green fluorescent protein, Trastuzumab, Probiotics

- Steps before

- Media preparation, Sterilization of equipment, Inoculum preparation

- Steps after

- Harvesting biomass, Downstream processing, Product purification

- Input ingredients

- bacteria, fungi, yeasts, plant cells, animal cells, microalgae, macroalgae

- Output ingredients

- proteins, monoclonal antibodies (mAb), cell suspension

- Market info

- Volume

- 1–10 L

- Material

- 316L steel + borosilicate glass

- Sterilization

- Autoclavable

- Agitation

- Direct top drive or bottom magnetic clutch

- Measurement and control

- Temperature, agitation speed, pH, DO, medium flow, antifoam/level, air flow (manual), pressure (manual)

- Advanced features

- Multi-channel feed system, second pump, vessel weighting system, pressure, optical density, cell suspension concentration monitoring, methanol, ethanol, redox sensors

- Configuration

- Batch and continuous cultivation

- Batch vs. continuous operation

- Batch / Continuous

- Automation level

- Manual / PLC / Customized modules

- Cleaning method

- Autoclavable

- CIP/SIP

- Autoclavable

- Supported Cultivations

- Bacteria, Fungi, Yeasts, Plant and Animal cells

- Material

- 316L steel + borosilicate glass

- Volume Capacity

- 1 – 10 L

- Footprint

- Table-mounted

- Discharge method

- Accessible connections for water and air

- Agitation type

- Direct top drive or bottom magnetic clutch

- Volume range

- 1–10 L

- Material

- 316L steel + borosilicate glass

- Agitation type

- Direct top drive or bottom magnetic clutch

- Sterilization method

- Autoclavable

- Customization availability

- Custom setup via questionnaire

- Construction type

- Table-mounted