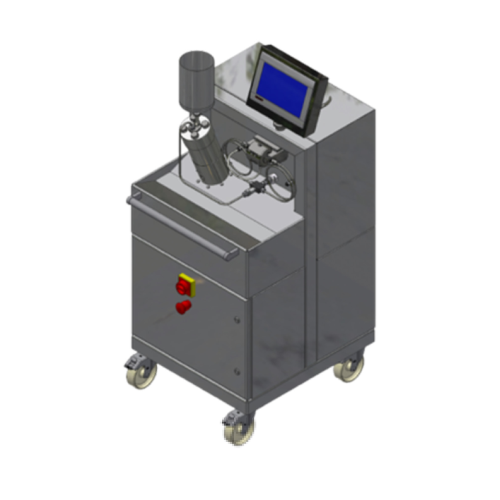

High pressure homogenizer for lab applications

Achieve precise control over droplet size and consistency in high-viscosity formulations while maintaining a clean and sterile environment, ideal for enhancing product quality in lab settings.

Homogenizes and Emulsifies Viscous Liquids

The ATOMIX® High Pressure Homogenizer Series from Kinematica AG is specifically engineered for high-performance processing in the pharmaceutical, nutraceutical, and cosmetic industries. It utilizes an optimized double piston pump with an electromechanical drive, ensuring silent, low-vibration operation and energy efficiency. The counter-jet type working chamber integrates radial diffusers to minimize cavitation, enhancing product quality and reducing equipment wear.

This homogenizer excels in producing stable emulsions for products such as omega-3 beverages, liposomal vitamin C, and hyaluronic acid creams. It achieves a maximum throughput of 1.2 L/min and operates at pressures up to 2500 bar, making it suitable for high-pressure lab applications and the production of highly viscous materials.

The design supports Clean-In-Place (CIP) and Sterilize-In-Place (SIP) operations, crucial for maintaining hygiene standards in pharmaceutical environments. With a 6 kW motor, the ATOMIX® reduces energy consumption by up to 30% for high-viscosity processes due to its efficient motor design, eliminating the need for additional cooling systems. This adaptability ensures seamless integration into your existing production line, supporting advanced research and development goals.

Benefits

- Enables precise mixing with minimal pressure loss, enhancing product consistency.

- Slashes energy usage by 30%, boosting operational cost efficiency.

- Supports CIP/SIP for contamination-free production cycles.

- Achieves narrow droplet size distribution, crucial for superior product quality.

- Operates silently, reducing noise pollution in lab environments.

- Applications

- Highly viscous materials, Nutraceuticals, Cosmetics, Pharmaceuticals

- End products

- Concentrated fruit purees, Protein carrier emulsions, Plant-based nutraceuticals, Eye creams, Topical ointments, Cannabis-infused oils, Omega-3 fortified beverages, Retinol creams, Liposomal vitamin c supplements, Anti-aging skin serums, Hyaluronic acid creams, Injectable vaccines

- Steps before

- Emulsification, Mixing, Pre-homogenization

- Steps after

- Sterilization, Filling, Packing, Quality Control

- Input ingredients

- highly viscous materials, nutraceutical ingredients, cosmetic ingredients, pharmaceutical ingredients

- Output ingredients

- small droplets, narrow droplet size distribution, improved product quality

- Market info

- Max throughput

- 1.2 L/min

- Max working pressure

- Max. 2500 bar

- Motor power

- 6 kW

- Cleaning method

- CIP / SIP

- Droplet size distribution

- Small droplets, narrow distribution

- Energy reduction

- 30% reduced energy at high viscosities

- Design type

- Counter-jet interaction chamber with radial diffuser

- Pump type

- 1-piston, electric

- Noise Level

- Quiet (due to electromechanical operation)

- Pulsation

- Pulsation-free conveyance

- Working Mechanism

- Double piston pump, electromechanical

- Integrated Steps

- Pulsation-free conveyance

- Cleaning Method

- CIP / SIP

- Batch vs. Continuous Operation

- Batch

- Automation Level

- Automated with silent electric pump

- Energy Efficiency

- 30% reduced energy at high viscosities

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Ideal for highly viscous material

- CIP/SIP Capability

- Yes

- Cavitation Control

- Special design for limited cavitation

- Pulsation-free Operation

- Phase-shift for pulsation-free conveyance

- Pressure Loss

- Minimal due to optimized design

- Droplet Size Control

- Small droplets and narrow droplet size distribution

- Phase-shift Operation

- Provides pulsation-free conveyance

- Machine footprint

- Compact design

- Control panel type

- Touchscreen

- Discharge method

- Pulsation-free conveyance

- Customization for Pharma applications

- CIP / SIP

- Machine noise level

- Low

- Working chamber design

- Counter-jet with radial diffuser