R&d and process development freeze dryer

Speed up your biologic development with precise lyophilization control, ensuring rapid cycle optimization and scale-up for high-value biopharmaceuticals and diagnostics.

Optimizes Freeze-Drying for Biologics

The Hull LyoStar 4.0 R&D Freeze Dryer from SP Industries is designed to accelerate your biopharmaceutical process development. It excels in the precise control of freeze-drying cycles, enhancing the stability and integrity of sensitive biologic materials. Utilizing advanced Process Analytical Technology (PAT) tools, it offers unparalleled uniformity in shelf temperature mapping and rapid shelf freezing, making it ideal for applications such as developing monoclonal antibodies and mRNA vaccines. This pilot-scale lyophilizer supports seamless scale-up from development to production, while its eco-friendly refrigerant systems reduce the carbon footprint. The LyoStar 4.0 is 21 CFR Part 11 compatible, ensuring compliance with stringent regulatory standards, and integrates smoothly into cleanroom environments with available CIP systems for efficient maintenance. It can be customized with accessories like ControLyo® nucleation technology to meet specific operational needs, delivering consistent results in high-quality biologic freeze-drying.

Benefits

- Speeds up time-to-market by reducing cycle development time with advanced process control.

- Conserves valuable biological materials with precise temperature control and optimized drying cycles.

- Ensures compliance with 21 CFR Part 11 standards for reliable data integrity and regulatory readiness.

- Integrates seamlessly into various production environments, maintaining product quality and safety.

- Minimizes environmental impact through energy-efficient operation and eco-friendly refrigerants.

- Applications

- Organic solvent products, Vials, Biopharmaceuticals, Serum bottles, Diagnostic kits

- End products

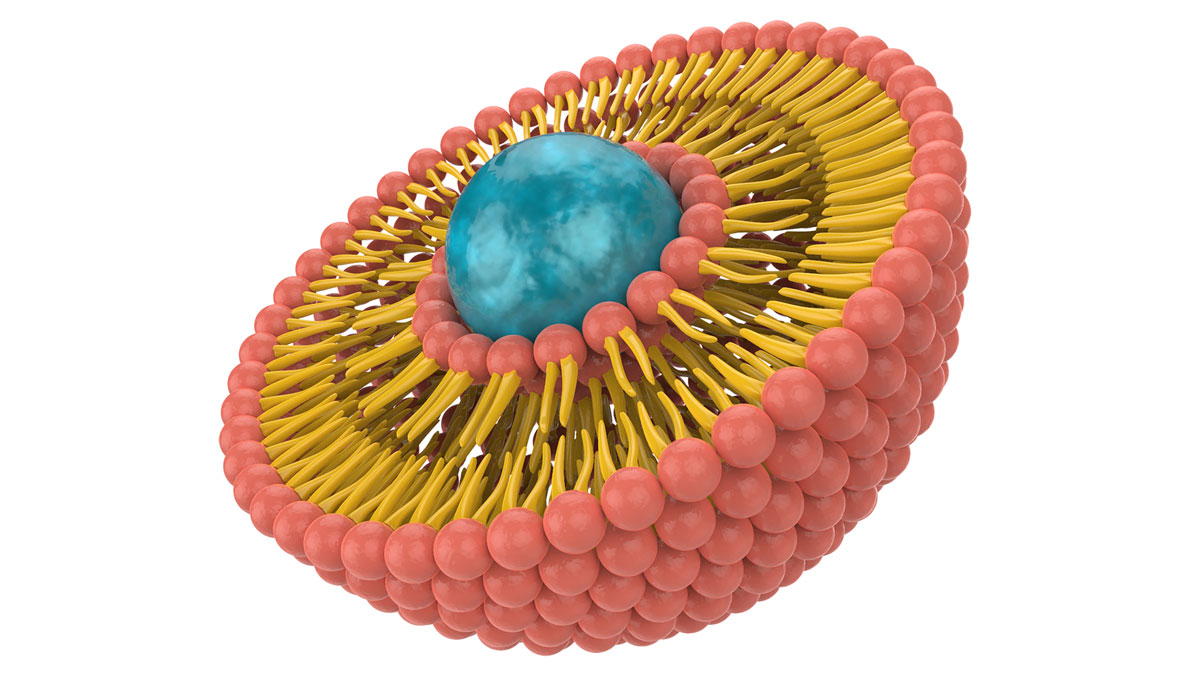

- Protein-based therapeutics, Injectable biomolecules, Monoclonal antibodies, Covid-19 diagnostic kits, Liposomal formulations, Enzyme formulations, Mrna vaccines, Liquid biopsy test kits, Bacteriophages, Peptide therapeutics

- Steps before

- Formulation, Mixing, Sample Preparation

- Steps after

- Stability Testing, Quality Control, Packaging

- Input ingredients

- biologic materials, organic solvents, water, diagnostic samples, formulation samples, serum, 96-well plates, bottles, vials

- Output ingredients

- lyophilized products, freeze-dried samples, stabilized formulations, cake with controlled resistance

- Market info

- Shelf temperature mapping

- Superior

- Shelf freezing rate

- Rapid

- Process control

- Precise

- Refrigerant gas

- Eco-friendlier

- Cycle development time

- Decreased

- API conservation

- Conserves valuable API

- Process Analytical Technology (PAT) tools

- Included

- Freezing point control

- Pinpoint

- Product temperature measurement

- Real-time

- Cycle development speed

- Rapid

- Process control precision

- High reliability

- Batch Operation

- Yes

- Shelf freezing rate

- Rapid

- Environmental impact

- Eco-friendly refrigerant

- Scale-up capability

- Pilot-scale to full production

- Process Analytical Technology (PAT) tools

- Included

- Density/particle size

- 0.5–2.5 g/cm³

- 21 CFR Part 11

- Compatible

- Compact footprint

- Designed for pilot-scale

- Compact structure

- Shelf temperature mapping

- Superior uniformity

- Shelf freezing

- Rapid shelf freezing capability

- Control panel type

- Integrated with advanced PAT tools

- Discharge method

- Contains extraction and leveling accessories

- Eco-friendliness

- Reduced carbon footprint with eco-friendlier refrigerant gas

- Cleanroom compatibility

- Optional integration into cleanroom or isolator environments

- Control panel type

- Optional 21 CFR Part 11 compatible software