High-speed blister packaging with integrated cartoner

Optimize your blister packaging process with a solution that seamlessly integrates high-speed cartoning, reducing downtime and maximizing efficiency for continuous operations.

Forms, Seals, and Cartons Blister Packs Efficiently

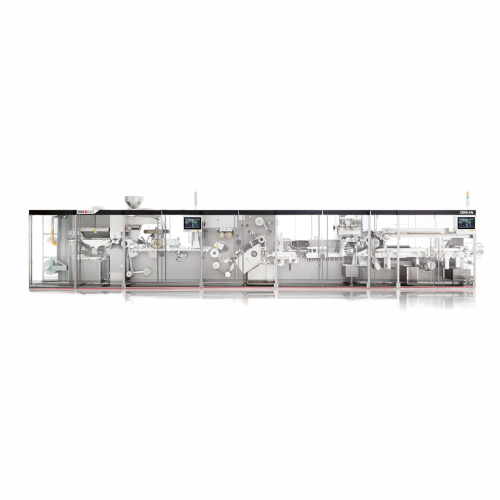

The C80HS from IMA Safe is a high-speed blister packaging and cartoning machine engineered for pharmaceutical and packaging companies aiming to streamline tablet, supplement, and vitamin production. This dual-lane system forms, seals, and cuts blister packs, then seamlessly integrates cartoning operations, achieving impressive throughput up to 750 blisters and 500 cartons per minute. Its modular design supports compatibility with various cartoners and downstream systems. Equipped with an automatic blister recovery magazine and innovative cutting unit, it ensures minimal waste and uninterrupted processing. The machine optimizes energy consumption and is constructed with materials suitable for recyclable and compostable packaging. Designed for compliance with pharmaceutical standards, the C80HS offers intuitive operation, rapid changeovers, and easy maintenance, making it a versatile choice for high-demand production environments.

Benefits

- Achieves high-speed production with up to 750 blisters and 500 cartons per minute.

- Minimizes waste with automatic blister recovery, ensuring seamless operations even with downstream interruptions.

- Flexible integration with multiple cartoners enhances production line adaptability.

- Energy-efficient operation aligns with sustainability goals, reducing overall consumption.

- Facilitates rapid product changeovers, optimizing production time and efficiency.

- Applications

- Vitamins, Supplements, Pharmaceutical tablets, Nutraceuticals, Pharmaceutical packaging

- End products

- Calcium supplement blister packs, Vitamin d tablets blister packs, Aspirin blister packs, Fish oil capsules blister packs, Multivitamin tablets blister packs

- Steps before

- Material preparation, Reel loading, Pre-heating

- Steps after

- Cartoning, Flowpacking, End-of-line packaging, Tracking and Serialization

- Input ingredients

- blister materials, forming materials, cartons

- Output ingredients

- blisters, cartoned products, packaged products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Blister dimensions

- Width

- Cartons dimensions

- Width

- Production output

- 750 blisters/min

- Cartons/minute

- Up to 500 cartons/min

- Integrated cartoner speed

- Up to 500 cartons/min

- Energy consumption

- Reduced to a minimum

- Automation

- Automatic blister recovery magazine

- Modularity

- Integration with different cartoners

- Rejection reduction

- Minimum thanks to blister recovery magazine

- Cutting unit

- Innovative with different shape rejection

- Blister transfer

- Positive and independent from blister shape

- Size changeover

- Quick and easy

- Automation level

- High – PLC/SCADA controlled

- Batch vs. continuous operation

- Continuous

- Blister recovery capability

- Automatic with ZERO rejection

- Modularity

- Integration with different cartoners

- Changeover time

- Quick and easy

- Energy efficiency

- Reduced energy consumption

- Process speed

- Up to 750 blisters/minute, 500 cartons/minute

- Energy consumption

- Reduced to a minimum

- Blister material

- Suitable for various shapes

- Carton material

- Supports different styles

- Blister machine type

- Double-lane

- Cartoner integration

- Compatible with different cartoners

- Accessibility

- Complete accessibility in connection area

- Reel holder position

- Ergonomic

- Blister recovery magazine

- Automatic

- Machine configurations

- C80HS-A96, C80HS-A86, C80HS-A76, C80HSA Stand Alone

- Integration possibilities

- Compatible with different cartoners

- Modularity

- Can integrate with downstream machines like cartoners, wallet packers, flowpackers

- Automatic blister recovery

- ZERO rejection into the cartoner

- Size changeover

- Quick and easy