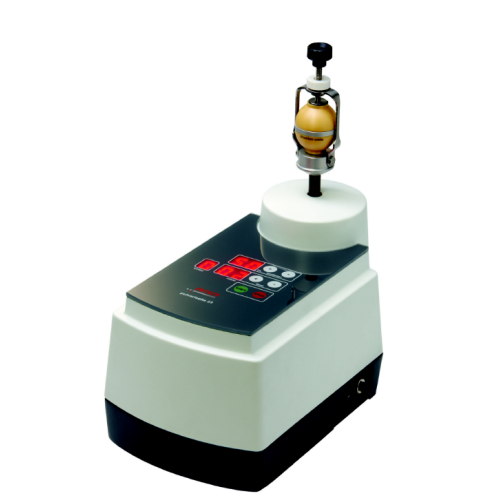

Mini-mill for fine comminution of small sample quantities

Achieve precise homogenization and fine comminution of small sample quantities, essential for laboratories needing efficient preparation for subsequent analytical procedures. Ideal for applications demanding meticulous control over particle size and sample integrity.

Grinds and Homogenizes Laboratory Samples

The Mini-Mill PULVERISETTE 23 from FRITSCH is a compact ball mill designed for precise sample grinding in laboratories across various industries. Utilizing impact and friction, it ensures effective comminution of small sample quantities from 0.1 ml to 5 ml. Ideal for biotechnology, pharmaceuticals, and material technology, it processes samples for applications ranging from cell lysis to particle size reduction. The mill features a unique spherical grinding bowl that enhances grinding performance while facilitating easy cleaning and maintenance. With its bench-top design, the unit seamlessly integrates into lab environments, offering manual operation and high-speed oscillations of 900 to 3,000 per minute. Customizable with different material options to prevent contamination, it supports rigorous sample preparation with minimal user intervention.

Benefits

- Enhances analytical accuracy by ensuring precise sample comminution.

- Saves lab space with its ultra-compact bench-top design.

- Minimizes sample contamination with material-specific grinding bowls.

- Simplifies cleaning procedures with easy-to-disassemble components.

- Facilitates diverse applications from biotechnology to environmental testing with versatile operation modes.

- Applications

- Chemicals, Ceramics, Biotechnology, Mineralogy, Metallurgy, Food industry, Material technology, Environmental research, Forensic analysis, Textiles, Pharmaceuticals

- End products

- Textile fiber analysis, Metal particle size reduction, Soil sample preparation, Mineral powders, Fungus cell disruption, Food ingredient testing, Azo dye detection in textiles, Yeast cells lysis, Ceramic powders, Deep frozen tissue homogenization, Drug particles preparation

- Steps before

- Sample Collection, Pre-crushing, Drying, Freezing

- Steps after

- Particle Analysis, Material Classification, Sample Analysis

- Input ingredients

- medium-hard samples, brittle samples, moist samples, fungus cells, yeast cells, deep frozen tissue, cells

- Output ingredients

- fine comminution, homogenized samples, nano-particles

- Market info

- Fritsch is renowned for manufacturing high-quality, engineered-to-order laboratory instruments for sample preparation and particle sizing in research and industrial laboratories, with a strong reputation for precision, innovation, and reliability.

- Sample capacity

- Up to 5 ml

- Oscillation frequency

- 900 - 3, 000 oscillations/min

- Amplitude

- 9 mm

- Grinding bowl volume

- 0.1 ml – 5 ml

- Oscillation frequency range

- 15 – 50 Hz

- Footprint

- 20 x 30 cm

- Weight

- 7 kg

- Grinding method

- Impact and friction

- Working mechanism

- Impact and friction

- Grinding bowl oscillations

- 900 - 3, 000 oscillations/min at 9 mm amplitude

- Oscillation frequency

- 15 – 50 Hz

- Automatic operation level

- Manual

- Cleaning method

- Simple and manual

- Batch size capacity

- 0.1 ml – 5 ml

- Abrasion resistance

- Spherical grinding bowls

- Biological compatibility

- PTFE grinding bowls

- Corrosive resistance (e.g. acids)

- Zirconium oxide grinding bowls and balls

- Cleanability

- Easy-to-clean glass keyboard

- Density/particle size

- Medium-hard to moist samples

- Sizes up to 5 ml

- Grinding Type

- Dry/Wet/Cryogenic

- Machine footprint

- 20 x 30 cm

- Machine weight

- 7 kg

- Grinding bowl shape

- Spherical

- Compact footprint

- 20 x 30 cm

- Weight

- 7 kg

- Control panel type

- Integrated, easy-to-clean glass keyboard

- Grinding bowl material

- PTFE / Zirconium Oxide

- Grinding bowl capacity

- 0.1 ml – 5 ml

- Oscillation frequency range

- 900 - 3, 000 oscillations/minute

- Grinding method

- Impact and friction

- Cooling option

- Pre-cool in liquid nitrogen

- Operation Type

- Wet, dry, cryogenic grinding

- Spherical Grinding Bowl

- Twist and turn assembly