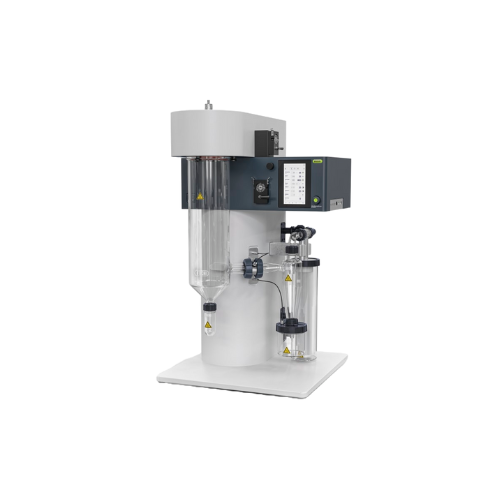

Laboratory spray dryer for organic solvent samples

Experience precise particle control and enhanced safety when converting liquid samples into fine powders, ensuring optimal product stability and uniformity for advanced formulations.

Enables Precision Spray Drying and Encapsulation

The Mini Spray Dryer S-300 from BUCHI Labortechnik is a laboratory-scale spray dryer designed for precision in particle formation and encapsulation processes. This equipment excels with its automation capabilities, allowing programmable sequence modes and remote operation for optimized workflows. The dryer effectively handles a range of applications, producing end-products such as solid dispersions and encapsulated nutrients. With a maximum throughput of 1 liter per hour for water and up to 250°C inlet temperature, it efficiently facilitates drying and atomization processes. Its energy efficiency is enhanced with an inert loop to safely process organic solvents. Constructed from high-grade materials with options for corrosive environments, it ensures robust operation and longevity. Compliance with laboratory safety standards and easy maintenance via a user-friendly interface underscores its suitability for pharmaceutical, chemical, and food industries.

Benefits

- Enhances precision in particle size control, improving formulation quality.

- Minimizes sample loss with coated cyclone, increasing yield efficiency.

- Supports flexible research setups with remote monitoring and control.

- Ensures safety and efficiency in handling organic solvents with integrated inert loop.

- Simplifies scale-up and formulation reproduction with programmable method management.

- Applications

- Vitamins, Proteins, Cosmetics, Functional foods, Catalysts, Chemicals, Fragrances, Cells, Batteries, Nano materials, Bacteria, Probiotic bacteria, Additives, Milk powder, Paints, Pharmaceuticals, Nutraceuticals, Coatings, Flavors, Juice concentrate

- End products

- Flavored drink mixes, Encapsulated baking flavors, Dairy-based vitamin supplements, Nanoparticles, High-protein meal replacements, Probiotic yogurt cultures, Solid dispersions, Probiotic dairy supplements, Anti-aging skincare serums, Vitamin-enriched functional drinks, Controlled-release drug formulations, Microencapsulated fragrance oils, Time-release energy supplements, Encapsulated fish oil, Pigment dispersions for automotive paint, Enhanced plant-based protein powders, Anti-corrosive coatings, Metal oxide catalysts, Long-lasting perfume oils, Inhalable dry powders, Taste-masked oral formulations, Lithium-ion battery cathode powders

- Steps before

- Solution preparation, Suspension preparation, Sample emulsification

- Steps after

- Powder collection, Product analysis, Packaging, Storage

- Input ingredients

- water, organic solvents, acids, alkalines, liquid solutions, suspensions

- Output ingredients

- dry powders, solid dispersions, inhalable drugs, taste-masking particles, controlled-release formulations, nanoparticles, nanostructured materials, fine and uniform particles

- Market info

- Buchi is renowned for its expertise in laboratory and industrial solutions, particularly in producing high-quality equipment for chemical analysis and lab processes, known for precision and reliability in the pharmaceutical, chemical, and food industries.

- Evaporation Capacity

- 1.0 L/h H2O, higher for organic solvents

- Final Particle Size

- 1 - 60 μm

- Yield

- up to 70%

- Automation Level

- Highest level of automation and flexibility

- Method Programming

- Available

- Remote Control Possibilities

- Available

- Maximum Inlet Temperature

- 220°C / 250°C

- Nozzle Type

- Two fluid, three fluid, ultrasonic

- Sample Composition

- Water, organic solvents, acids, alkalines

- Auto Mode

- Available

- Sample Throughput (H2O)

- 1 L/h

- Coated Cyclone

- Available for increased yields

- Outlet Temperature Monitoring

- Available

- Process Data Reporting

- PDF and .csv format

- Drying Gas

- Nitrogen/Different gases in SI Values

- Automation level

- Manual / Auto

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Density/particle size

- 1–60 μm

- Discharge method

- Connected to the Inert Loop S-395 for safe organic solvent handling

- Control panel type

- User interface with remote control options

- Automation level

- Manual / Auto Mode / Method Mode

- Integration possibilities

- Remote monitoring via mobile app

- User interface

- Method programming and sample queue setup

- Reporting options

- PDF report or .csv file generation