Spray drying solution for uniform powder production

Achieve seamless transformation of liquid feeds into uniform, free-flowing powders while maintaining product integrity, thanks to advanced atomization and precise drying control.

Produces Uniform, Free-Flowing Fine Powders

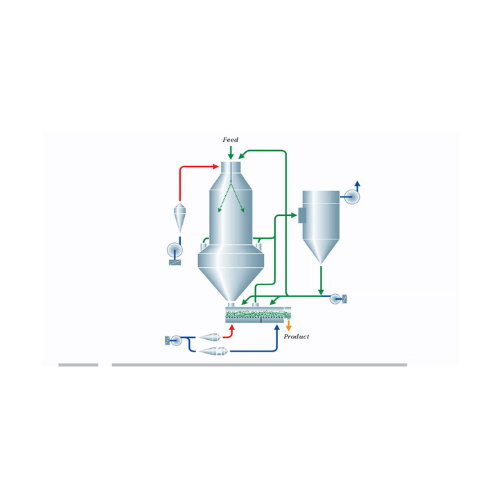

The NOZZLE TOWER Spray Dryer from GEA is engineered to produce uniform, free-flowing powders by leveraging precise nozzle atomization within its advanced drying chamber design. This equipment is particularly suitable for diverse industries such as food, chemical, dairy, and pharmaceuticals, tackling the production of whey powder, instant coffee, and various pharmaceutical excipients. Utilizing a controlled airflow and nozzle arrangement, it facilitates gentle drying and extended particle residence time for optimal moisture removal and particle uniformity.

Capable of handling continuous, high-speed operations, the NOZZLE TOWER integrates seamlessly into production lines thanks to its automated processing and advanced control systems. This dryer not only reduces energy consumption through effective air disperser design but also offers customization with counter-current versions for heavy feed stocks. Its robust construction is available in materials compatible with your specific chemical processing needs, ensuring durability and corrosion resistance.

With the inclusion of SANICIP® Bag Filters, the system ensures efficient separation and potential re-use of fine particles, enhancing both yield and product consistency. It adheres to industry standards, including GMP compliance for pharmaceutical applications, and offers CIP systems for efficient, contamination-free cleaning. This supports minimal downtime and maintenance, maximizing operational efficiency and throughput.

Benefits

- Enhances product consistency with uniform particle size and free-flowing powders.

- Optimizes energy use through efficient air disperser and nozzle configuration.

- Complies with GMP and FDA requirements, ensuring quality for pharmaceutical production.

- Minimizes operational costs with automated, high-speed continuous processes.

- Offers flexible integration with customizable setups for different production needs.

- Applications

- Food, Chemicals, Ingredients, Nutraceuticals, Beverage, Processed foods, Powdered foods, Coating materials, Industrial chemicals, Dairy, Pharmaceuticals

- End products

- Detergent powders, Vitamins, Spray-dried flavors, Protein concentrates, Industrial enzymes, Infant formula, Fruit juice powders, Dense milk powder, Whey powder, Ceramic powders, Powdered drink mixes, Coating pigments, Bioactive peptides, Instant coffee, Pharmaceutical excipients

- Steps before

- Emulsification, Initial Drying, Atomization Preparation

- Steps after

- Cooling, Agglomeration, Packing, Bagging-off

- Input ingredients

- liquid feedstock, heavy feed stocks, heat-sensitive materials

- Output ingredients

- uniform powder, free-flowing powders, individual round particles, soluble particles, agglomerated powders, coarse agglomerated powder, dustless powder

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Powder production capability

- Uniform fine particles

- Nozzle type

- Fountain nozzles

- Drying process

- Controlled low velocity airstream

- Air disperser design

- Designed for low velocity airstream downwards

- Residence time

- Long residence time in drying chamber

- Particle processing

- Gentle drying of particles

- Air exhaust method

- Bustle with enlarged conical section

- Post-drying treatment

- Pneumatic cooling and conveying system

- Pre-cooling

- Cooling air introduced into lower chamber cone

- Working mechanism

- Nozzle spray drying

- Drying process

- Controlled low velocity airstream

- Drying method

- Atomization by nozzles

- Air disperser design

- Ensures gentle drying

- Powder production

- Free-flowing, round particles

- Drying chamber exhaust

- Bustle system

- Agglomeration option

- Recycling via nozzles

- Counter-current version

- Available for heavy feed stocks

- Particle Separation

- SANICIP® Bag Filter

- Cooling integration

- Pneumatic cooling system

- Residence time

- Long residence time in chamber

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Low

- Machine footprint

- Depends on specific design and setup

- Cone shape

- Enlarged conical section for drying chamber

- Discharge method

- Pneumatic cooling and conveying system

- Nozzle type

- Fountain nozzles for heavy feed stocks

- Control panel type

- PLC-controlled

- Discharge method

- Bagging-off / pneumatic cooling and conveying