Flexible transport robot for packaging lines

Enhance your packaging efficiency with a transport robot engineered to seamlessly integrate complex processes, ensuring flexibility and high-speed operation across diverse product formats.

Streamlines Packaging, Transport, and Grouping Processes

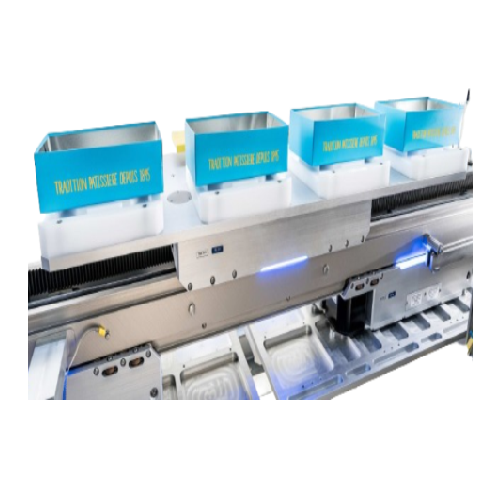

The Transmodul Transport Robot from Schubert is a state-of-the-art solution designed for seamless packaging automation in diverse industries such as food, pharmaceuticals, and cosmetics. This versatile transport robot excels in streamlining numerous packaging processes, from grouping to cartoning and labeling, within a highly efficient and modular system. Its unique capability to independently navigate various stations ensures seamless integration and flexibility in production lines, accommodating rapid product changes and high-speed operations.

Notably, the Transmodul reduces production downtime with its robust system components and inherent redundancy, allowing continued operation even if one module fails. The robot’s modularity enables quick adaptation to new formats, including 3D-printed parts, optimizing packaging for a broad range of solid and liquid products, such as madeleines, skincare bottles, and plasma preparations.

Energy efficiency is a key feature, achieved through inductive power supply with energy recuperation from braking. The durable construction and sophisticated signal management ensure high reliability, while gentle handling protects product integrity throughout transport. Schubert supports customization with engineering assistance, ensuring the system meets specific production requirements effectively.

Benefits

- Enhances production flexibility with quick format changes and modular tools.

- Increases line efficiency by maintaining operations even if a module fails.

- Optimizes space with a compact layout and high-density power distribution.

- Reduces energy costs via inductive power supply and energy recuperation.

- Protects product quality during transport with gentle handling and precise robotic tools.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Bakery products, Dairy, Pharmaceuticals

- End products

- Biscuits, Small cakes, Remoulades, Barbecue sauces, Skincare products, Health and wellness bottles, Madeleines, Human plasma preparations, Body care products, Mozart balls, Wafer rolls

- Steps before

- Product grouping, Component assembly

- Steps after

- Cartoning, Palletizing, Product labeling, Closure, Filling

- Input ingredients

- packaged products, erected cartons, filled packages, product components, folding cartons, mixed formats, special tin formats, human plasma preparations

- Output ingredients

- ready-for-sale products, grouped product components, secondary packaging, bottles, jars, folding cartons, trays, packaged products in different formats and container sizes

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Automation

- Cross-process, seamless, and flexible

- Efficiency

- High machine availability and line efficiency

- Cycle time

- Adaptable to almost any cycle time

- Power supply

- Inductive with buffer storage

- Energy efficiency

- High power density

- Recuperation of braking energy

- Load capacity

- High load capacity

- Modularity

- High level of modularity

- Redundancy

- System-inherent redundancy for machine availability

- Format change capability

- Quick adaptation to new formats

- Tools

- Individually designed robotic tools

- Footprint

- Compact layout

- Compatibility

- Suitable for a wide range of products and sectors

- Automation level

- Fully automatic

- Changeover time

- Quick changeover

- Energy efficiency

- High energy efficiency with recuperation

- CIP/SIP

- Not applicable

- Cleaning method

- Not specified

- Flexibility

- Highly flexible with modular tools

- Process integration

- Seamless and interface-free

- Load capacity

- High load capacity

- Cycle time adaptation

- Flexible cycle time adaptation

- Redundancy

- System-inherent redundancy

- Failure backup

- Continuous operation with reduced output

- 3D printing compatibility

- Yes, via Schubert PARTBOX

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Space-saving layout

- Modularity

- Easily replaceable modules

- Format parts adaptability

- 3D-printed format parts

- Control panel type

- HMI/Touchscreen

- Integration possibilities

- Seamlessly integrates with existing packaging lines

- Modular tools

- 3D-printed format parts

- Exchangeable base plate

- Double

- Adaptability to formats

- Quick format changes