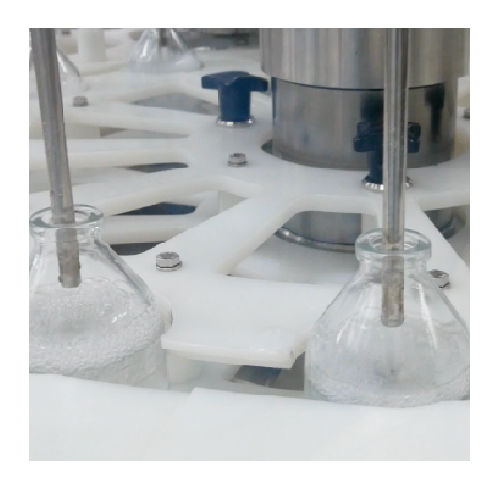

Rotary vial filling and stoppering system

For high-speed production of sterile injectable vials, this continuous motion rotary system ensures precise filling and stoppering, maintaining aseptic conditions and maximizing throughput efficiency.

Fills, Stopper, and Caps Liquid Vials

The RFS-100/200 HYGEIA from Siempharma is a cutting-edge rotary vial filling and stoppering machine designed to meet the stringent requirements of aseptic production environments. It excels in handling liquid formulations across pharmaceuticals, nutraceuticals, and cosmetics with precision and speed, accommodating up to 200 vials per minute. This continuous motion machine integrates seamlessly into existing lines, featuring a user-friendly touch screen HMI for rapid setup and operation, and it supports CFR21 part 11 / EU ANNEX 11 compliance for data integrity. The robust design includes AISI 304 stainless steel construction and clear segregation of vial transport from drive mechanisms to ensure hygiene and minimal wear. Options for on-board or separate alu-capping stations add flexibility, while an automatic rejection system removes faulty vials without disrupting workflow. Customizable to fit production needs, this machine aligns with GMP standards and offers efficient cleaning and low maintenance, making it a reliable asset in high-volume production settings.

Benefits

- Enhances production efficiency with continuous high-speed filling and stoppering operations.

- Minimizes maintenance needs with durable design and low-wear components.

- Ensures sterility and safety with robust compliance to GMP standards.

- Streamlines changeovers and cleaning with user-friendly design.

- Maintains product integrity with automatic rejection of compromised vials.

- Applications

- Liquid formulations, Nutraceuticals, Aseptic products, Cosmetics, Pharmaceuticals

- End products

- Moisturizing creams, Anti-aging serums, Essential oil vials, Oral liquid syrups, Vitamin supplements, Fish oil capsules, Herbal extract vials, Eye drops, Sterile injectable vials, Vaccine vials, Hormone vials

- Steps before

- Purification, Aseptic Preparation, Solution Mixing

- Steps after

- Capping, Aluminum Sealing, Sterilization, Quality Control, Packaging

- Input ingredients

- vials, rubber stoppers, alu-seals, liquid products, lyo products

- Output ingredients

- filled vials, stoppered vials, capped vials, faulty vials

- Market info

- Filling speed

- Up to 200 pieces per minute

- Filling volume

- Small to large volume vials (up to 500 ml)

- Automation

- User-friendly Touch Screen HMI

- Compliance

- CFR21 part 11 / EU ANNEX 11 ready

- Industry Standard

- INDUSTRY 4.0 compliant

- Maintenance

- Minimal maintenance required

- Material

- AISI 304 stainless steel panels

- Stoppering Method

- Full or partial rubber stoppering

- Capping type

- Pressure rubber stopper + alu-seals

- Changeover

- Easy change size parts

- Working Mechanism

- Continuous Motion

- Integrated Steps

- Filling, Stoppering, Capping

- Automation Level

- PLC Controlled

- Changeover Time

- Easy Change Size Parts

- CIP/SIP

- Manual

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Designed to Facilitate Cleaning

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Container type

- Vials / Bottles

- Container size

- Up to 500 ml

- Filling purpose

- Liquid / Lyo products

- GMP Compliance

- Yes

- CE marking

- Yes

- INDUSTRY 4.0 standard

- Yes

- CFR21 part 11 / EU ANNEX 11

- Ready

- Control panel type

- Touch Screen HMI

- Discharge method

- Outfeed conveyor belt

- Control panel type

- User-friendly Touch Screen HMI

- Integration possibilities

- Integration of alu-capping station on board (monobloc solution)