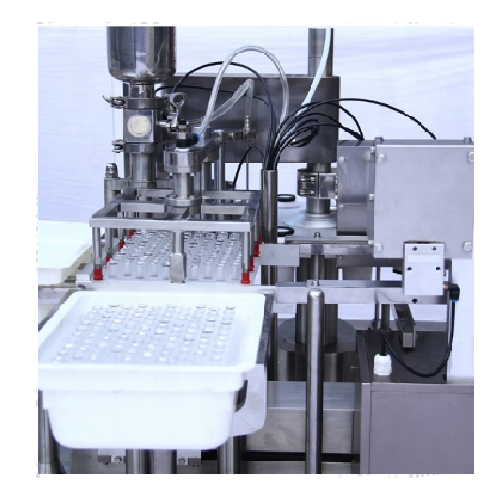

Automatic syringe de-nester for pharmaceutical production

Streamline your syringe production line with high-speed de-nesting, ensuring gentle handling and precise integration into subsequent processes like inspection, plungering, and labeling.

De-nests and Transfers Syringes in Production Lines

The AD-200 APES from Siempharma is an advanced syringe handling solution designed for automated de-nesting and the precise downstream transfer of syringes in pharmaceutical, nutraceutical, and cosmetic production lines. This equipment ensures smooth integration with optical inspection units, plungering, and labeling machines, facilitated by its brushless motor and robotic systems that provide gentle syringe handling.

The system is capable of managing processes, including de-nesting, feeding, sorting, and transferring, contributing to a seamless production flow for pre-filled, vaccine, insulin, hyaluronic acid, vitamin, and dermatological treatment syringes. The AD-200 APES operates continuously at high speeds, optimizing production efficiency.

It features a full AISI 304 stainless-steel structure and is compliant with GMP standards, CE regulations, and Industry 4.0 requirements. Equipped with a user-friendly Touch Screen HMI, it allows quick learning and fast configuration, supporting a wide range of customization options. Moreover, the machine’s design ensures ease of cleaning and maintenance, making it an ideal choice for high-quality production environments.

Benefits

- Minimizes syringe handling damage with precise robotic transfer systems.

- Enhances production efficiency by integrating seamlessly with existing inspection and labeling processes.

- Reduces operational costs through high-speed continuous operation.

- Ensures compliance with industry standards, supporting GMP regulations and Industry 4.0 integration.

- Simplifies maintenance with easily accessible design and intuitive interface.

- Applications

- Nutraceuticals, Cosmetics, Pharmaceuticals

- End products

- Insulin syringes, Hyaluronic acid syringes, Vaccine syringes, Vitamin syringes, Pre-filled syringes, Dermatological treatment syringes

- Steps before

- Syringe Nesting, Pre-printed Data Decoding

- Steps after

- Optical Inspection, Plungering, Labelling

- Input ingredients

- syringes in nests, syringes in tubs, syringes in rondo trays

- Output ingredients

- de-nested syringes, syringes ready for downstream processing, syringes for optical inspection, syringes for plungering, syringes for labelling

- Market info

- Automation

- Automatic

- Main Drive

- ESV (electronic speed variation)

- Motor Type

- Brushless motors

- Operation Interface

- Touch Screen HMI

- Nest Removal System

- Automated

- Syringe Handling

- Gentle handling

- Tub Infeed Buffers

- FIFO policy

- Syringe Transfer Robot System

- Precise and gentle transfer

- Automation level

- Fully Automated

- Changeover time

- Quick and simple

- Cleaning method

- Designed for easy cleaning

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- 0

- Energy efficiency

- 0

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Nest/Tub, Rondo tray

- Machine structure material

- AISI 304 stainless-steel

- Safety guards

- Aluminum frame and Lexan doors

- Control panel type

- Touch Screen HMI

- Changeover simplicity

- Quick and simple

- Accessibility

- Full accessibility for easy management, inspection, and maintenance

- Visibility

- Complete visibility of the working process

- Control panel type

- Touch Screen HMI

- Integration possibilities

- In-line connections with conveyors

- Drive system customization

- Electronic Speed Variation (ESV)

- Industry 4.0 readiness

- Yes

- Safety features

- Safety guards with interlock switches

- Compliance

- CFR21 part 11 / EU ANNEX 11

- Material

- AISI 304 stainless-steel