Lab powder dispenser for precision measurements

Effortlessly streamline your lab’s powder dispensing tasks with a versatile solution, designed to accurately measure and distribute precise quantities, reducing manual handling time and enhancing consistency in sample preparation.

Dispenses Precise Powder and Bead Volumes

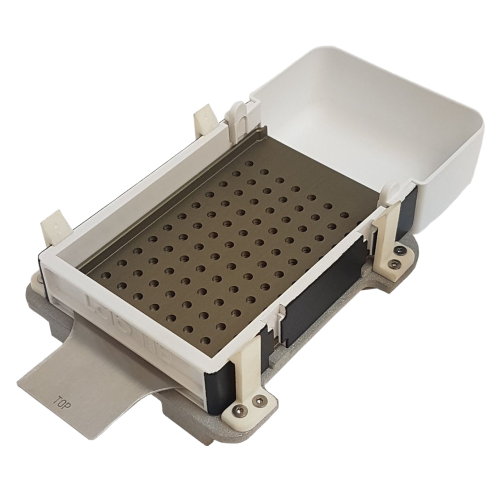

The LabTIE Powder Dispenser is a modular sample dispenser designed for versatility in laboratory and biotech applications. This semi-automated device significantly reduces manual workload by accurately dispensing powder and bead volumes ranging from 5 µL to 1000 µL. It employs interchangeable mesh plates for adaptive use with various industry-standard containers, including tubes, vials, and microtiter plates. Ideal for laboratory powders and fine chemicals, it serves sectors such as biotech, pharmaceuticals, and nutraceuticals, facilitating the production of clinical reagents, enzyme blends, and pharmaceutical formulations. Crafted from anodized aluminum with anti-static properties, it minimizes material interaction and is easy to clean. Custom parts are available to cater to specific requirements in powder types or non-standard containers, ensuring seamless integration into existing laboratory workflows.

Benefits

- Enhances productivity by minimizing hands-on time in powder dispensing tasks.

- Allows precise control of powder volumes, ensuring consistent sample preparation.

- Versatile design accommodates multiple container types, facilitating workflow flexibility.

- Easy-to-clean anodized aluminum construction reduces contamination risks.

- Customizable components adapt to unique laboratory needs, ensuring operational efficiency.

- Applications

- Laboratory powders, Biotech industry, Fine chemicals, Nutraceuticals, Enzymes, Laboratory beads, Laboratory reagents, Reagents, Pharmaceutical powders

- End products

- Microscopic spheres, Precision dosage powders, Nutritional supplements, Encapsulated drug powder, Enzyme blends, Chemical compounds, Laboratory assay kits, Clinical reagents, Powdered nutrients, Pharmaceutical formulations

- Steps before

- Grinding

- Steps after

- Packing

- Input ingredients

- powders, beads smaller than 0.3 mm

- Output ingredients

- dispensed powder, dispensed beads

- Market info

- Molgen is known for manufacturing customized engineered-to-order (ETO) equipment, specializing in tailored solutions for complex industrial needs. Their expertise lies in innovative engineering, delivering high-quality, precise, and reliable machinery that meets specific client requirements.

- Operation Mode

- Manual/Semi-automated

- Volume Range

- 5 µL – 1000 µL

- Container Compatibility

- Tubes, Vials, Microtiter and deep-well plates

- Custom Parts Availability

- On Request

- Mesh Plate Feature

- Anodized aluminium with anti-static properties

- Standard Grids

- 24-well, 48-well, 50-well, 96-well, 100-well, 384-well

- Working mechanism

- Manual sample dispenser with exchangeable mesh plates

- Integrated steps

- Pulled slider for dispensing

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal, involves exchanging mesh plates

- Cleaning method

- Easy to clean design

- Material compatibility

- Compatible with various powder types

- Customizability

- Custom parts for unique powder types/weights, grids

- Cleanability

- Easy to clean

- Anti-static properties

- Anodized aluminium mesh plate

- Compatibility with bead size

- Beads smaller than 0.3 mm

- Machine footprint

- Varied based on sample and container

- Discharge method

- Manual pulling of slider

- Mesh plate

- Anodized aluminium with anti-static properties

- Modular design

- Yes

- Mesh plate exchangeability

- Available

- Custom part availability

- On request

- Grid sizes

- 24 to 384

- Container compatibility

- Standard, custom on request