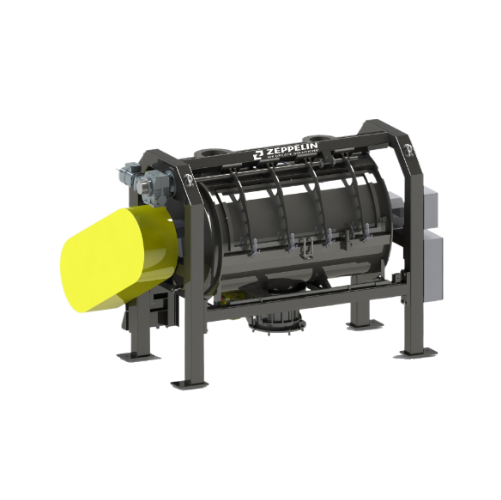

Horizontal homogenizing mixer for all-purpose applications

Achieve uniformity and consistency in your products with a versatile mixer designed for efficient homogenization—ideal for processes requiring gentle blending of diverse materials without compromising texture or integrity.

Homogenizes and Mixes Rubber, Plastics, and Paints

The HCH Horizontal Homogenizing Mixer from Zeppelin Systems is engineered to deliver uniform mixing and homogenization across a range of industries including rubber, tire, food, plastics, and chemical sectors. With its robust stainless steel construction, this mixer ensures reliable performance in processing solid, powder, and granular materials. The HCH mixer stands out due to its variable tool configuration, allowing it to adapt to diverse homogenization tasks while maintaining a high filling range. Designed for both batch and continuous operations, it seamlessly integrates into existing production lines. Although it lacks cooling capabilities on container surfaces, the mixer is optimized for gentle mixing processes, making it ideal for delicate materials such as latex paints and snack mixes. This equipment supports efficient processing and is available in corrosion-resistant materials, ensuring longevity in harsh operating environments. With its engineered-to-order design, customization options are available to meet specific processing requirements.

Benefits

- Achieves consistent homogenization, ensuring product quality across operations.

- Minimizes downtime with robust construction and reliable performance.

- Adapts to diverse processing needs with configurable tool setups.

- Supports flexible production methods, accommodating both batch and continuous operations.

- Ensures long-term durability with corrosion-resistant material options.

- Applications

- Food, Tires, Plastics, Dispersion paints, Rubber

- End products

- Tire treads, Latex paints, Snack mixes, Rubber sheets, Plastic pellets

- Steps before

- Mixing, Compounding

- Steps after

- Homogenization, Storage, Packaging, Quality Control

- Input ingredients

- materials for homogenization, stainless steel mixing container input

- Output ingredients

- homogenized mixture, gently homogenized materials

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Material

- Stainless steel

- Automation

- PLC-controlled

- Design

- Single-walled container

- Filling Range

- High

- Cooling Facility

- No cooling capability

- Tool Configuration

- Variable

- Homogenization

- Gentle

- Homogenization type

- Gentle

- Tool configuration variability

- Variable

- Filling range

- High

- Batch vs. continuous operation

- Batch

- Container cooling

- None

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Single-walled stainless steel

- Suitable materials

- All types

- Mixing container material

- Stainless steel

- Mixing container design

- Single-walled

- Tool configuration

- Variable

- Filling range

- High

- Mixing tool configuration

- Variable

- Mixing container type

- Stainless steel, single-walled

- Filling range

- High

- Cooling facility

- None on container surfaces

- Gentle homogenization

- Special tool design