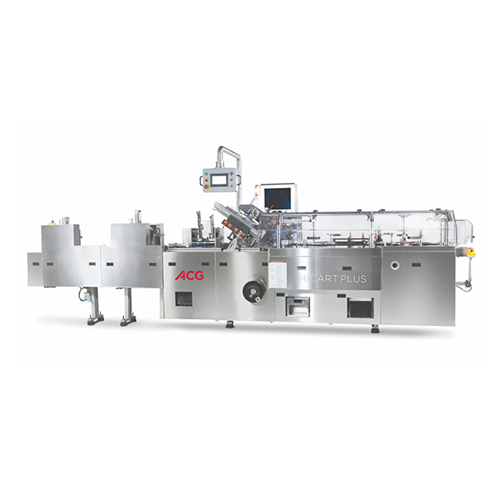

Continuous cartoning solution

Enhance your production line with efficient high-speed cartoning, designed to streamline packaging of various forms, from blister packs to bottles, while ensuring error-free operation with its ‘No product-No leaflet-No carton’ system.

Cartons and Packages Varied Rigid Products

The HICART PLUS from ACG is a continuous cartoning machine adept at integrating high-speed packaging solutions. It stands out for its ability to handle diverse rigid products like tablets, ampoules, vials, and more. This machine employs a multi-chain configuration, optimizing carton sizes for various applications. It boasts a processing throughput of up to 180 cartons per minute, seamlessly integrating with existing blister packaging, conveyor systems, and upstream machinery. The built-in ‘No product-No leaflet-No carton’ system ensures error-free output and minimal waste. Available material options cater to industry needs for corrosion resistance, and its energy-efficient design meets rigorous pharmaceutical and nutraceutical standards. Customization options, including extendable conveyors and carton closure types, provide tailored solutions for specific operations, while compliance with GMP standards ensures reliability and quality in production lines.

Benefits

- Increases packaging efficiency with continuous high-speed cartoning, minimizing process delays.

- Ensures product integrity and reduces waste with error-prevention systems.

- Adapts to various packaging sizes and configurations, offering flexibility for diverse production needs.

- Streamlines operational integration with upstream and downstream equipment for seamless workflow.

- Complies with pharmaceutical standards, ensuring high-quality, regulation-compliant packaging.

- Applications

- Sachets, Vials, Tubes, Blister packs, Ampoules, Soaps, Bottles, Pouches, Bags

- End products

- Toothpaste tubes, Sugar sachets, Sauce pouches, Snack bags, Antibacterial soaps, Cold and flu tablets, Vitamin ampoules, Shampoo bottles, Vaccine vials

- Steps before

- Blister Packaging Preparation, Leaflet and Booklet Preparation, Product Sorting

- Steps after

- Packing, Labeling, Sealing

- Input ingredients

- blister packs, ampoules, vials, bottles, tubes, pouches, bags, sachets, soaps

- Output ingredients

- cartons

- Market info

- ACG World is known for manufacturing capsules and capsule filling machines, providing integrated pharmaceutical solutions with a strong reputation for innovation, quality, and comprehensive service offerings in the pharmaceutical manufacturing industry.

- Maximum output

- 180 cartons/min

- Carton width (2-Chain)

- Min 20 mm, Max 75 mm

- Carton width (3-Chain)

- Min 20 mm, Max 75 mm

- Carton width (4-Chain)

- Min 20 mm, Max 75 mm

- Carton height

- Min 20 mm, Max 65 mm

- Carton length (2-Chain)

- Min 45 mm, Max 70 mm

- Carton length (3-Chain)

- Min 65 mm, Max 180 mm

- Carton length (4-Chain)

- Min 95 mm, Max 200 mm

- Carton type

- Reverse tuck-in, glued type, parallel tuck-in

- Automation

- Built-in ‘No product-No leaflet-No carton’ system

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Various

- Packaging type

- Blister packs, ampoules, vials, bottles, tubes, pouches, bags, sachets, soaps

- Machine footprint

- Compact

- Pitches and chain configurations

- Various

- Carton width

- 20 mm - 100 mm

- Carton height

- 20 mm - 65 mm

- Carton length

- 45 mm - 200 mm

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Compatible with blister packaging, upstream and downstream equipment

- Conveyor extension option

- Available