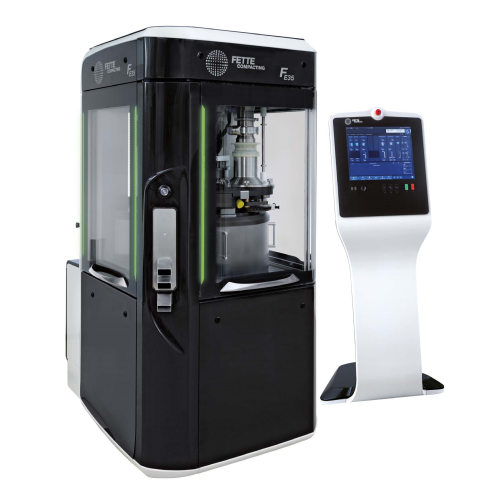

High-capacity tablet press for pharmaceutical production

Achieve precise compression and consistent tablet density with a compact design, maximizing production efficiency even in high-speed operations.

Compresses and Fills Tablets Efficiently

The FE Series from Fette Compacting offers a range of high-speed tablet presses ideal for pharmaceutical, nutritional supplement, and food industry manufacturers. Engineered with the unique TRI.EASY design, these machines facilitate seamless operation, refitting, and servicing, enhancing overall production efficiency. Equipped with the Fill-O-Matic system, the tablet presses ensure accurate powder filling and dosing, reducing product loss through a precision-controlled, three-chamber filling system. Designed for continuous automatic operation, the FE Series meets diverse application needs including aspirin, vitamin supplements, and effervescent tablets, with outputs reaching up to 1.65 million tablets per hour in the FE75 model. The machines are constructed with high-quality stainless steel components for easy cleaning and hygiene compliance. Configurable with SmartInterface for advanced automation integration and available containment options, the FE Series supports pharmaceutical GMP compliance and rapid changeovers to maintain high production uptime.

Benefits

- Increases production efficiency with high-speed output and minimized changeover times.

- Ensures consistent tablet quality and density using precise dosing and filling technology.

- Simplifies operation and maintenance with user-friendly TRI.EASY design.

- Promotes hygiene and compliance with easy-to-clean stainless steel construction.

- Facilitates quick integration into existing production lines with automation and SmartInterface compatibility.

- Applications

- Food industry, Nutritional supplements, Pharmaceutical tablets

- End products

- Herbal nutrition tablets, Multivitamin gummies, Vitamin d supplements, Effervescent tablets, Fish oil capsules, Protein tablets, Zinc lozenges, Magnesium supplements, Aspirin tablets, Caffeine tablets

- Steps before

- Mixing, Granulation, Blending, Weighing

- Steps after

- Coating, Quality Control, Packing, Labeling

- Input ingredients

- powder, pharmaceutical materials, nutritional supplements, food industry materials

- Output ingredients

- tablets, pharmaceutical tablets, nutritional supplement tablets

- Market info

- Fette Compacting is renowned for its advanced tablet press technology, offering high-performance machines and process equipment for the pharmaceutical and nutraceutical industries, emphasizing innovation, quality, and efficiency in tablet production.

- Tablet output

- 367, 200 tablets per hour

- Tablet output

- 626, 400 tablets per hour

- Tablet output

- 1, 656, 000 tablets per hour

- Tablet size

- up to 25 mm

- Stations

- 51 max

- Stations

- 87 max

- Stations

- 115 max

- Dimensions (FE35)

- Height

- Width

- 1, 042 mm

- Depth

- 1, 336 mm

- Weight (FE35)

- approx. 3, 000 kg

- Dimensions (FE55)

- Height

- Width

- 1, 626 mm

- Depth

- 1, 306 mm

- Weight (FE55)

- approx. 4, 000 kg

- Dimensions (FE75)

- Height

- Width

- 1, 778 mm

- Depth

- 1, 463 mm

- Weight (FE75)

- approx. 5, 300 kg

- Automation

- Compatible with SmartInterface

- Design

- TRI.EASY Design

- Filling system

- Fill-O-Matic

- Construction Material

- High-quality stainless steel

- Automation level

- PLC

- Batch vs. continuous operation

- Batch

- Changeover time

- Short

- CIP/SIP

- Easy cleaning

- Cleaning method

- Manual

- Efficiency enhancement

- Efficiencyplus

- Stainless Steel

- Contact parts made of stainless steel

- Cleanability

- High, due to stainless steel surfaces

- Compact footprint

- Yes, high production potential and compact design

- Machine height

- FE35

- FE55

- 2, 048 mm

- FE75

- 2, 046 mm

- Machine width

- FE35

- FE55

- 1, 626 mm

- FE75

- 1, 778 mm

- Machine depth

- FE35

- FE55

- 1, 306 mm

- FE75

- 1, 463 mm

- Machine weight

- FE35

- FE55

- approx. 4, 000 kg

- FE75

- approx. 5, 300 kg

- Tablet size

- 25 mm max

- Control panel type

- HMI (Human Machine Interface)

- Machine integration

- Compatible with SmartInterface

- Design Concept

- TRI.EASY Design

- Fill System

- Fill-O-Matic

- Containment Option

- Available