Continuous dosing and blending for pharmaceutical powders

Optimize your pharmaceutical production with precise dosing and consistent blending of powders, ensuring higher blend uniformity and efficient integration into continuous processes.

Performs Precision Dosing and Blending of Powders

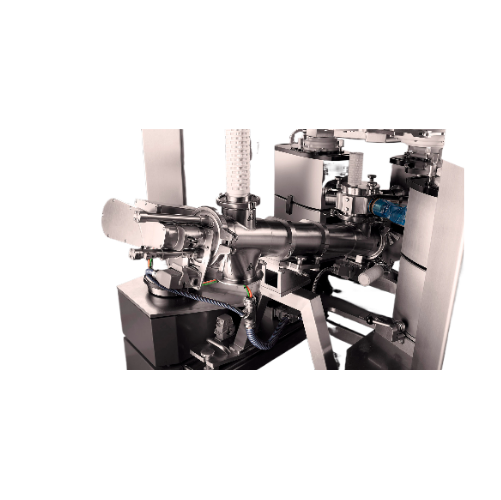

The ConsiGma® Dosing and Blending (DB) Modules from GEA are designed to streamline pharmaceutical production with precise, continuous dosing and blending of powders. Leveraging advanced integration capabilities, these modules seamlessly incorporate into existing continuous manufacturing lines, featuring either ribbon or linear blenders for scalable throughput from 1 to 400 kg/h. Ideal for applications ranging from low-dose aspirin to high-potency medications, the modules support both R&D and full-scale production. Managed by Conductor 4.0 software, they provide comprehensive process control, material tracking, and OOS monitoring, enhancing operational efficiency. Compatible with both continuous and mini-batch processes, they offer flexible material options and adhere to GMP standards, ensuring high-quality output with every batch.

Benefits

- Enhances blend uniformity, ensuring consistent product quality across batches.

- Offers flexible throughput capacities from low to high API content, adapting to various production needs.

- Minimizes process disruption by integrating seamlessly into existing lines, adhering to SUPAC guidelines.

- Improves material yield through precise dosing and blending, optimizing resource use.

- Provides real-time in-process control and monitoring, reducing quality control efforts.

- Applications

- Pharmaceutical tablets, Nutraceuticals, Generic pharmaceuticals, Cmo operations, Ethical pharmaceuticals

- End products

- Vitamin d supplements, Low-dose aspirin tablets, High-potency prescription drugs, Generic ibuprofen capsules, Contract-manufactured vitamins

- Steps before

- Purification, Drying, Pre-blending, Grinding

- Steps after

- Tablet Pressing, Coating, Packing

- Input ingredients

- external phase additions, lubricant, pre-blend, flowable powder materials, NCE (New Chemical Entities), orphan drugs, low-dose APIs

- Output ingredients

- blended powder, homogeneous blend, high material yield

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Throughput Capacity

- 1 to 400 kg/h

- Dosing Capability

- Standalone continuous dosing

- Blending Capability

- Standalone continuous blending

- Software Control

- Conductor 4.0

- Feeder Configuration

- 2 to 4 loss-in-weight feeders

- Blender Type

- Linear or ribbon blender

- Integration Capability

- With any continuous up- or downstream process

- In-process Control

- Blend uniformity with Lighthouse Probe®

- OOS Tracking

- Integrated tracking

- Process Control

- Seamless control and full reporting

- Blending Options

- Continuous flow or mini-batch

- Tablet Press Interface

- Customer selected (GEA or other)

- Working mechanism

- Continuous dosing and blending

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC-controlled

- CIP/SIP

- CIP available

- Cleaning method

- CIP

- Energy efficiency

- High material yield, low energy consumption

- Changeover time

- Minimal impact

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Blend type

- Ribbon or linear blender

- Throughput capacity

- 1 to 400 kg/h

- Configuration

- Standalone or integrated

- Integration possibilities

- Handshaking with up- or downstream equipment

- Feeder Choice

- GEA or qualified third-party supplier

- Blender type

- Linear or ribbon blender

- Blending capability

- Continuous flow or mini-batch blending

- Tablet press compatibility

- GEA or other – control interface to be clarified