In-motion bottle filling system for pharmaceuticals

Boost your production efficiency with our high-speed bottle filling system that accurately counts and fills up to 200 bottles per minute, integrating seamless quality inspection and adaptable modular configurations to fit your needs. Ideal for optimizing solid dose packaging lines.

Counts and Fills Tablets and Capsules

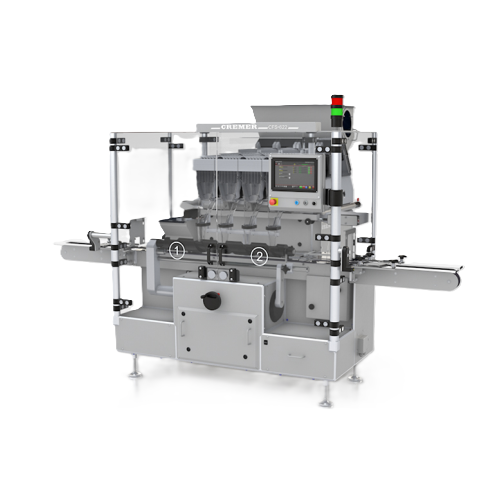

The CFS series from Cremer is a specialized counting and filling machine designed for pharmaceutical and nutraceutical applications. This compact machine stands out for its precise and scalable performance, accommodating up to four counting modules, thus optimizing space with a small footprint. It operates based on a six-channel tablet and capsule counting module, allowing filling rates of up to 200 bottles per minute without requiring format parts. The CFS series efficiently counts and fills a wide range of solid dosages, including tablets, capsules, gelcaps, and more, making it highly versatile for products like aspirin, vitamin D capsules, and omega-3 supplements. Integrating seamlessly into high-speed, automated lines, it offers GMP-compliant design featuring intuitive HMI controls, ensuring operational safety and ease of cleaning. For enhanced quality assurance, the BottleChrom inspection system with Single Tablet Reject function enables real-time detection and removal of defective products, preventing bottlenecks. Constructed from pharmaceutical-grade materials, it is engineered for durability and can be easily maintained with an optional cleaning trolley. Cremer offers customization options, allowing tailored solutions that meet specific production needs.

Benefits

- Enhances production efficiency with up to 200 bottles per minute throughput.

- Ensures product quality with real-time defect detection and removal.

- Simplifies integration into existing lines with a compact, flexible design.

- Reduces cleaning time with autoclave-friendly, pharmaceutical-grade components.

- Provides customizable configurations to meet specific production demands.

- Applications

- Vitamins, Supplements, Pharmaceutical tablets, Nutraceuticals, Gelcaps, Capsules

- End products

- Vegan omega-3 supplements, Calcium softgels, Vitamin d capsules, Coenzyme q10 gelcaps, Probiotic capsules, Fish oil gelcaps, Multivitamin tablets, B12 supplements, Aspirin tablets, Iron tablets

- Steps before

- Tablet pressing, Capsule production, Coating

- Steps after

- Packaging, Sterilization, Inspection, Quality control

- Input ingredients

- pills, tablets, hard capsules, softgel capsules, gelcaps

- Output ingredients

- filled bottles, packaged bottles

- Market info

- Cremer is known for designing and manufacturing precision counting machines, particularly in the pharmaceutical and food industries. Their expertise lies in innovative, accurate, and reliable counting solutions for tablets, capsules, and confectionery.

- Counting Accuracy

- 100%

- Max. Output

- 200 bottles/minute

- Bottle Height

- 35–200 mm*

- Bottle Diameter

- 20–125 mm

- Bottle Shape

- Round, oval, rectangular

- Solids Type

- Tablets, capsules, gelcaps

- Solids Length

- 3–30 mm

- Solids Diameter

- 3–20 mm

- Working mechanism

- Automatic counting and filling

- Integrated steps

- Counting, inspection, and filling

- Batch vs. continuous operation

- Batch

- Automation level

- PLC / HMI controlled

- Cleaning method

- Manual / Autoclave cleaning of parts

- CIP/SIP

- Not applicable, manual cleaning

- Changeover time

- Rapid, few change parts

- Energy efficiency

- N/A

- Footprint

- Compact

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Small

- Discharge Method

- Modular

- Control panel type

- Intuitive HMI control

- Integration possibilities

- Customizable for complete bottle filling and packaging lines

- Modular design

- Flexible placement of counting modules

- Optional features

- Cleaning trolley, Single Tablet Reject system

- Output scalability

- 1-4 counting modules configurability

- Custom applications

- Available for special product types