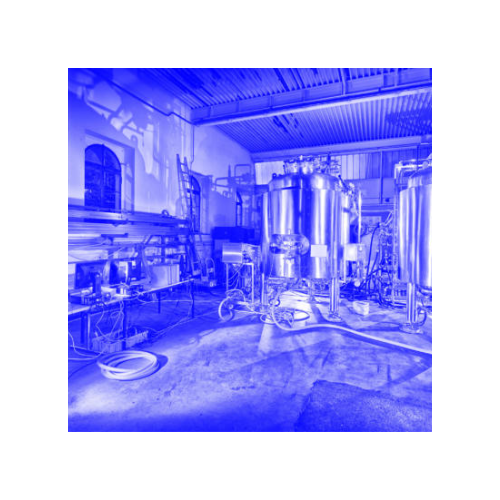

Formulation vessel for biopharmaceutical homogeneity

Achieve precise homogeneity in liquid formulations with vessels optimized for exact pH and temperature control, ensuring even distribution of active ingredients down to the final drop before transfer.

Mixes, Doses, and Homogenizes Liquid Formulations

Bioengineering’s stainless steel formulation vessels are designed for precision and reliability in biopharmaceutical production environments. These vessels ensure consistent mixing, dosing, and homogenizing of liquid formulations, crucial for the production of monoclonal antibodies, mRNA vaccines, and other high-value pharmaceuticals. Engineered for both manual and fully automated operations, they feature magnetic stirrers and optional vibromixers, which maintain homogeneity at various volume levels, even with complex suspensions. With capacities ranging from 50 to 2,500 liters, these vessels can handle a wide range of production scales. Each unit ensures meticulous control over temperature and pH, with integrated cooling and dosage systems to maintain product integrity from start to transfer. Standards-compliant and equipped with an isolated loop system for seamless integration into filling lines, the vessels offer comprehensive solutions for efficiency and adaptability in modern pharmaceutical processes. Designed for use in strict hygienic conditions, they meet cGMP and other global quality standards, ensuring compliance and reliability across applications.

Benefits

- Ensures precise formulation and consistency, vital for quality control in pharmaceutical production.

- Enhances operational efficiency with automated temperature and pH regulation.

- Facilitates seamless integration and transfer to filling systems, minimizing production delays.

- Meets stringent cGMP standards, ensuring compliance and reliability in regulated environments.

- Optimizes operation even at low fill levels, reducing material waste and maximizing yield.

- Applications

- Liquid formulations, Vaccines, Fine chemicals, Nutraceuticals, Biopharmaceuticals, Pharmaceutical products

- End products

- Vitamin d supplements, Liquid cough syrups, Monoclonal antibodies, Insulin formulations, Mrna vaccines, Biochemical reagents

- Steps before

- Purification, Mixing, Dosing, Temperature Adjustment

- Steps after

- Transfer to Filling Station, Packing, Sterilization, Quality Control

- Input ingredients

- active ingredient, stabilizers, buffers, additives, aluminum particles, liquids

- Output ingredients

- biopharmaceutical formulations, vaccines, pharmaceutical products

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Capacity

- 50–2, 500 liters

- Homogeneity

- Magnetic stirrers / Vibromixers

- Operation Capacity

- Low filling levels

- PH Level Control

- pH probe, controller and dosage systems

- Temperature Control

- Cooling systems

- Transfer Line

- Temperature-controlled

- Automation

- Manual / Fully automated

- Homogeneity control

- Magnetic and Vibromixer stirrers

- Automation level

- Manual / Fully automated

- PH level control

- pH probe, controller, and dosage systems

- Temperature control

- Cooling systems and temperature-controlled transfer lines

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP principles

- Tank shape and size

- 50–2, 500 liters

- Discharge method

- Controlled transfer to filling station

- Magnetic stirrers

- Standard

- Vibromixers

- Optional for suspensions

- Control panel type

- Manual / Fully Automated

- Mixing type

- Magnetic Stirrers / Vibromixers