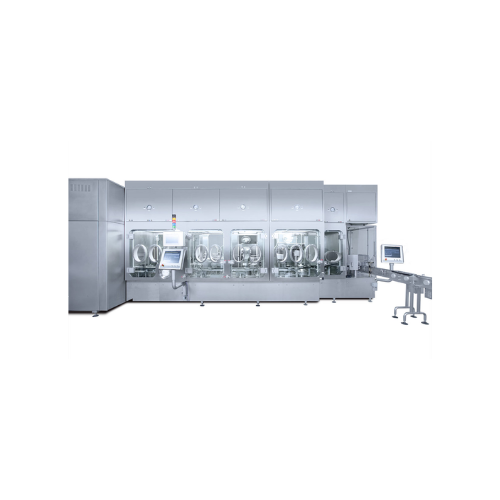

Filling and closing solution for vials and stable bottles

Optimize vial and bottle processing with a seamless solution designed for filling and closing, ensuring precise dosing and gentle transport, even at high speeds with continuous operation.

Fills and Closes Vials with Precision

The FVF series from Bausch+Ströbel offers compact and efficient solutions for vial filling and closing, ideal for pharmaceutical, biotech, and chemical industries. Designed with a walking beam system, it gently conveys stable containers through a multi-stage process that includes filling, dosing, and closing operations. Supporting both liquid and powder formulations, the series provides precise dosing with options like ECOfill and ADVANCEDfill, ensuring minimal product loss. With throughput capabilities of up to 24,000 items per hour and variable container sizes, the FVF series integrates seamlessly into high-speed, automated production lines. The machines are PLC-controlled, featuring remote monitoring and optional RABS or cleanroom isolators. Constructed to comply with GMP standards, they offer quick changeovers and are CIP/SIP compatible for efficient cleaning, catering to diverse production demands while maintaining product integrity and safety.

Benefits

- Enhances production efficiency with high-speed output of up to 24,000 vials per hour.

- Minimizes product loss through ultra-close dosing tolerances, ensuring optimal batch utilization.

- Integrates seamlessly into existing lines with flexible configurations for both liquid and powder products.

- Ensures compliance with GMP standards, supporting pharmaceutical-grade production requirements.

- Reduces manual intervention, enhancing operational safety and reliability.

- Applications

- Liquid formulations, Fine chemicals, Nutraceuticals, Pharmaceutical powder, Biopharmaceuticals, Pharmaceuticals

- End products

- Monoclonal antibody vials, Insulin vials, Protein shake containers, Oncology drug vials, Vitamin d supplements, Omega-3 oil capsules, Cough syrup bottles, Antibiotic powder bottles, Peptide vials, Vaccine vials

- Steps before

- Sterilization, Container Preparation

- Steps after

- Sealing, Inspection, Packing

- Input ingredients

- vials, stable bottles, glass containers, plastic containers, metal containers, liquid products, powder products

- Output ingredients

- filled vials, filled bottles, closed containers

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- Up to 24, 000 items/h

- Container Diameter

- 14.25 - 86 mm

- Container Height

- 30 - 180 mm

- Dosing Type

- Liquid and Powder

- Automation

- PLC-controlled

- Transport Method

- Walking Beam System

- SIP/CIP Compatibility

- SIP/CIP-compatible dosing components

- IPC

- 100% IPC at full output

- Closure Types

- Up to two different types of closure

- ECOfill System

- Ultra-close dosing tolerances

- ADVANCEDfill System

- Freely positionable needle holder

- Barrier Systems

- RABS and cleanroom isolator

- Working Mechanism

- Walking beam system, intermittent motion

- Gentle Container Transport

- Yes

- Automation Level

- PLC

- Batch vs. Continuous Operation

- Batch

- Changeover Time

- Short set-up time

- CIP/SIP

- SIP/CIP-compatible dosing components

- In-Process Control (IPC)

- 100% IPC at full output

- Zero-loss Start-up

- ECOfill system

- Energy Efficiency

- Resource-friendly technology

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Glass / Plastic / Metal

- Container diameter

- 14.25 - 90 mm

- Container height

- 30 - 180 mm

- Closure type

- Up to two different types

- Product type

- Liquid / Powder

- Dosing system

- Peristaltic pumps / Time-pressure / Powder dosing

- Processing range

- 6, 000 - 24, 000 items/h

- ISO Certification

- ISO 9001 / ISO 15378

- Machine footprint

- Compact

- Control panel type

- Easy and centralized operation

- Discharge method

- Walking beam system

- Container type

- Glass, Plastic, Metal

- Container diameter

- 14.25 - 86 mm

- Container height

- 30 - 180 mm

- Barrier systems

- RABS and cleanroom isolator

- Dosing systems

- Peristaltic pumps, time-pressure dosing system, powder dosing systems

- SIP/CIP compatibility

- SIP/CIP-compatible dosing components

- Service portal vision system

- Cleanroom compatible

- Softward upgrades

- Available

- Transport positions

- Variable number