Serialization system for flat cartons

Ensure precise serialization of flat cartons with integrated printing and inspection. Ideal for verifying and recording essential data while efficiently rejecting faulty items, this system enhances accuracy and quality control in your packaging processes.

Serializes and Inspects Flat Cartons

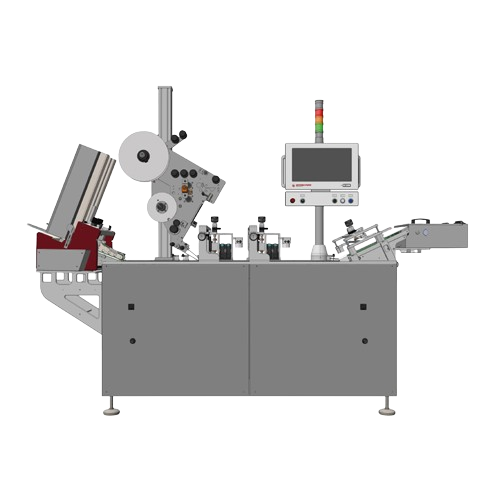

The Print & Check Flat Carton (VM3701) from Antares Vision Group is a semi-automatic, standalone serialization system designed for offline operations in packaging lines. It excels in marking, recording, and verifying serialization data, resolving the challenge of accurate tracking in pharmaceuticals, nutraceuticals, cosmetics, and food packaging. The VM3701 simplifies integration with its high-speed line, achieving up to 30 m/min, allowing customization based on carton size and offering multiple TIJ printing configurations. It incorporates an advanced camera system for inspection and a manual code reader for re-aggregation. Operable through an 18.5” touch screen, it supports operator interaction efficiently. While enhancing production efficiency, it also provides options for rejection systems, ensuring only fully compliant products move forward, ideal for pharmaceutical blister packs and ready-to-eat food packaging. The platform meets stringent industry standards, supporting customization such as varying conveyor lengths and carton collection units, and features robust construction for demanding environments.

Benefits

- Increases production efficiency by swiftly serializing and inspecting up to 30 meters of cartons per minute.

- Enhances product integrity with precise data verification and error rejection systems.

- Lowers operational costs through semi-automatic functionality and minimal manual intervention.

- Provides flexibility with customizable settings to accommodate various carton sizes and configurations.

- Ensures regulatory compliance across pharmaceutical and food industries with reliable serialization capabilities.

- Applications

- Beverage containers, Nutraceuticals, Cosmetics, Food packaging, Pharmaceuticals

- End products

- Cosmetic cream boxes, Beverage carton containers, Pharmaceutical blister packs, Nutraceutical supplement cartons, Ready-to-eat food packaging boxes

- Steps before

- Carton design, Carton production

- Steps after

- Packing, Distribution, Labeling, Sales

- Input ingredients

- flat cartons, empty boxes

- Output ingredients

- serialized cartons, printed and checked boxes, non-faulty cartons

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line speed

- Up to 30 m/min

- Conveyor length

- 3618 mm

- Working height

- 950 mm

- Product collection unit

- 1000 mm standard size

- Standard flat carton size

- A = 50–300 mm, B = 0.5–5 mm, C = 55–350 mm

- Printing technology

- TIJ 2.5

- Printing heads

- Up to 4

- Max resolution

- 600 dpi

- Datamatrix print quality

- Grade B typical

- Up to grade A

- N. of cameras for track,trace inspection

- Up to 2

- Serialization function

- Marking, recording, verification

- Feeding mechanism

- Collector to conveyor belt

- Error handling

- Faulty carton rejection system

- Automation level

- Semi-automatic

- Touch screen interface

- 18.5” touch screen

- Code reader

- Manual code reader for re-aggregation

- Adjustability

- Adjustable conveyor belt according to carton size

- Line speed

- Up to 30 m/min

- Conveyor belt material

- High grip rubber

- Abrasion resistance

- High grip rubber conveyor belt

- Cleanability

- Ergonomic design touch screen

- Density/particle size

- Supports flat carton sizes from 0.5-5 mm thickness

- Container type

- Flat carton

- Carton style

- Flat / Empty

- Container size

- A = 50-300 mm / C = 55-350 mm / B = 0.5-5 mm

- Printing method

- Thermal Inkjet (TIJ) 2.5

- Machine footprint

- Compact

- Conveyor length

- 3618 mm

- Product collection unit size

- 1000 mm standard

- Touch screen size

- 18.5 inches

- Working height

- 950 mm

- Standard flat carton size A

- 50-300 mm

- Standard flat carton size B

- 0.5-5 mm

- Standard flat carton size C

- 55-350 mm

- Control panel type

- 18.5” touch screen

- Conveyor belt adjustability

- Adjustable according to carton size

- Printing heads

- Up to 4 TIJ printing heads

- Rejection system

- Available on request

- Product collection unit size

- 1000 mm standard (other sizes available upon request)