Automatic in-line serialization and tamper-evident sealing unit

Ensure seamless serialization and secure packaging with precision printing and tamper-evident sealing, safeguarding your pharmaceutical products against counterfeiting and compliance issues.

Prints, Verifies, Serializes, and Seals Pharmaceutical Cartons

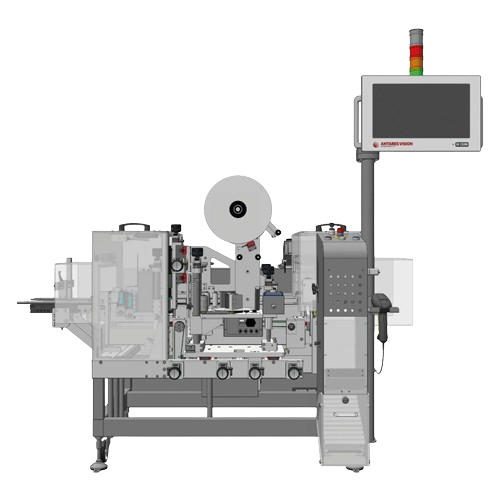

The Print & Check EVO-TE VM1900 from Antares Vision is a versatile standalone module designed for the pharmaceutical and life sciences sectors, focusing on serialization, verification, and tamper-evident sealing. This unit seamlessly integrates into both in-line and off-line operations, offering flexible application across diverse pharmaceutical packaging processes. With a line speed of up to 300 pcs/min, it efficiently handles blister packs, bottled supplements, and serialized vials while maintaining high-grade print quality and data accuracy.

The EVO-TE leverages Thermal Inkjet (TIJ) technology with up to four printing heads, ensuring precise marking monitored by integrated control cameras. Its dual-sided printing capability and tamper-evident application groups offer comprehensive product protection, while integrated track and trace systems ensure compliance with industry standards. Designed with an adjustable working height and extended conveyor length, it facilitates easy integration into existing production lines. The machine supports secure data management and offers a single Human Machine Interface (HMI) for streamlined operation, making it ideal for pharmaceutical manufacturers and packaging companies seeking to enhance product integrity and traceability.

Benefits

- Enhances product security with tamper-evident sealing.

- Ensures data integrity and traceability through advanced serialization.

- Increases operational efficiency with a high-speed capacity of up to 300 pcs/min.

- Streamlines integration with dual operational modes for in-line and off-line use.

- Simplifies system control and reduces error potential with a single HMI interface.

- Applications

- Biopharmaceuticals, Nutraceuticals, Pharmaceutical tablets, Pharmaceuticals

- End products

- Packaged prescription medicines, Serialized biopharmaceutical vials, Blister packs of tablets, Tamper-evident pharmaceutical cartons, Bottled dietary supplements

- Steps before

- Carton feeding, Input belt loading

- Steps after

- Tamper-evident sealing, Product rejection handling, Packing

- Input ingredients

- cartons, serialization data

- Output ingredients

- printed cartons, verified serialization data, rejected products

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line speed

- Up to 300 pcs/min

- Working height

- 800-1000 mm

- Conveyor length

- 1250 mm (+ 300 mm infeed conveyor)

- Printing heads

- Up to 4 (2 each printable side)

- Printing system

- TIJ 2.5 including print controller

- Ink cartridge

- Antares Vision Pharma Black (water based) or Industrial Black (solvent based)

- Max resolution

- 600 dpi

- Datamatrix print quality

- Grade B typical

- Up to grade A on selected backings acc. to ISO/IEC 15415-2

- Number of cameras for track,trace inspection

- Up to 2

- Standard carton size (A)

- 30–120 mm

- Standard carton size (B)

- 15–110 mm

- Standard carton size (C)

- 45–220 mm

- Working mechanism

- Standalone automatic unit

- Integrated steps

- Printing, Verification, Tamper-evident sealing

- Flow type

- In-line or off-line

- Line speed

- Up to 300 pcs/min

- Automation level

- Standalone automatic unit

- Conveyor system length

- 1250 mm (+ 300 mm infeed conveyor)

- Input method

- Input belt

- Carton size range

- A = 30-120 mm, B = 15-110 mm, C = 45-220 mm

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Not specified

- Standard carton size

- A = 30-120 mm / B = 15-110 mm / C = 45-220 mm

- Conveyor length

- 1250 mm (+300 mm infeed conveyor)

- Working height

- 800-1000 mm

- TIJ printing heads

- Up to 4

- Control panel type

- Single HMI

- Control panel type

- Single HMI

- Integration possibilities

- In-line or off-line