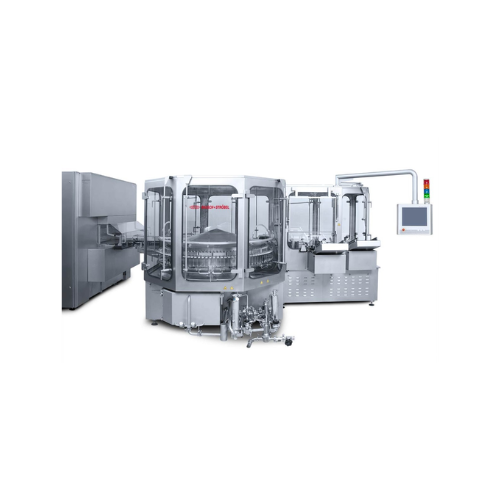

Compact cleaning system for glass and plastic containers

Ensure exceptionally thorough cleaning and gentle handling of diverse vial and bottle types with this high-speed system, optimizing your production line’s efficiency while preventing media cross-contamination.

Cleans and Transports Containers Continuously

The FAU Series from Bausch+Ströbel consists of high-speed container cleaning machines meticulously engineered for pharmaceutical and biotech productions. These machines excel at delivering intensive wet cleaning for glass vials, plastic ampoules, and medicine bottles, all in a continuous, gentle transport system. Each unit, including the FAU6000, FAU8000, and FAU12000, offers adaptable throughput, cleaning up to 36,000 containers per hour depending on the model. A distinguishing feature is its ECOwash technology, which ensures optimized cleaning with reduced water and air consumption by up to 40% and 20%, respectively. The system supports multiple cleaning media configurations without cross-contamination, enhancing flexibility across various applications from liquid pharmaceuticals to nutraceuticals. Integration into production lines is seamless, with options for ultrasonic pre-cleaning and automated monitoring systems. Designed for minimal setup time and ease of operation, the FAU Series aligns with GMP and FDA guidelines, supporting industry compliance while offering sound-insulated guarding and energy-efficient performance for sustainable operations. Customization, including additional cleaning media and specialized cleaning needles, ensures this series meets specific production needs.

Benefits

- Increases productivity with high-speed cleaning up to 36,000 containers per hour.

- Minimizes resource use, cutting water consumption by up to 40% and air consumption by up to 20%.

- Enhances process flexibility with customizable cleaning sequences and media configurations.

- Ensures compliance with GMP standards and FDA guidelines, supporting regulatory needs.

- Lowers operational noise and energy use through ECOwash technology, promoting sustainable practices.

- Applications

- Liquid formulations, Medical devices, Nutraceuticals, Biopharmaceuticals, Healthcare products, Pharmaceutical formulations

- End products

- Medicine bottles, Pharmaceutical plastic containers, Glass vials, Plastic vials, Nutraceutical bottle packaging, Medical device cleaning containers, Liquid medication bottles, Ampoules, Injectable glass containers, Biopharmaceutical ampoules

- Steps before

- Container sorting, Initial inspection

- Steps after

- Sterilization, Drying, Final inspection, Packing

- Input ingredients

- vials, bottles, ampoules, glass containers, plastic containers, non-stable containers

- Output ingredients

- clean vials, clean bottles, clean ampoules, clean glass containers, clean plastic containers, clean non-stable containers

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Machine Type

- Compact cleaning machine

- Output Capacity

- FAU6000

- Container Diameter Range

- 7.5 - 52 mm

- Container Height Range

- 35 - 140 mm

- Cleaning Schematic

- Freely selectable

- Pre-Cleaning Method

- Ultrasonic bath

- Container Transport

- Gentle, continuous motion

- Automation Level

- Easy and centralized operation

- Water Recycling Station

- Integrated, retractable

- Cleaning Media

- Configured to prevent mixing

- Sound Insulation

- Sound-insulated machine guard

- Water Heating

- Continuous flow water heater

- Filter Type

- Fine and HEPA filters

- Pressure Monitoring

- Differential pressure monitoring system

- CIP/SIP Version

- Available for fine and HEPA filters

- Heating Option

- Electric heater for ultrasonic bath

- ECOwash System Efficiency

- Reduction in water, residual moisture, air consumption, and noise

- GMP Compliance

- Meets applicable requirements

- FDA Guideline Compliance

- 21 CFR Part 11

- Cleaning method

- Ultrasonic bath / Wet cleaning

- Automation level

- Easy and centralized operation

- Changeover time

- Short set-up time

- CIP/SIP

- Manual / CIP version

- Container transport

- Gentle and continuous motion

- Energy efficiency

- High energy efficiency

- Batch vs. continuous operation

- Continuous flow

- Media usage ordering

- Freely selectable

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Vials, bottles, ampoules, non-stable containers

- Machine footprint

- Compact

- Control panel type

- Easy and centralized operation

- Container size

- Diameter

- Container transport

- Gentle and continuous motion

- System configuration

- Preconfigured for a 4th cleaning medium

- Sound-insulated machine guard

- Yes

- Water recycling station

- Integrated, retractable

- Extended infeed belt

- Mobile version

- ECOwash system

- Container-optimized cleaning needles

- Transition and linkage

- To machine downstream

- Sound-insulated machine guard

- Optional

- Water recycling station

- Integrated, retractable

- Cleaning media configuration

- Preconfigured for a 4th cleaning medium

- Container cleaning system

- Container-optimized cleaning needles

- Silicone treatment system

- Atomizer nozzles with "no container – no silicone" check

- Ultrasonic bath

- Individual transport for plastic containers

- Booster pumps

- Optional

- Compressor unit

- Oil-free air supply

- Service portal vision system

- Cleanroom compatible

- Software upgrades

- Available

- Extended infeed belt

- Mobile version