Controller for pilot and production scale bioreactors

Optimize your bioprocess with a robust, configurable controller designed to seamlessly integrate with pilot and production bioreactors, ensuring precise control and measurement for your cultivation processes.

Controls and Integrates Bioprocesses for Pilot and Production

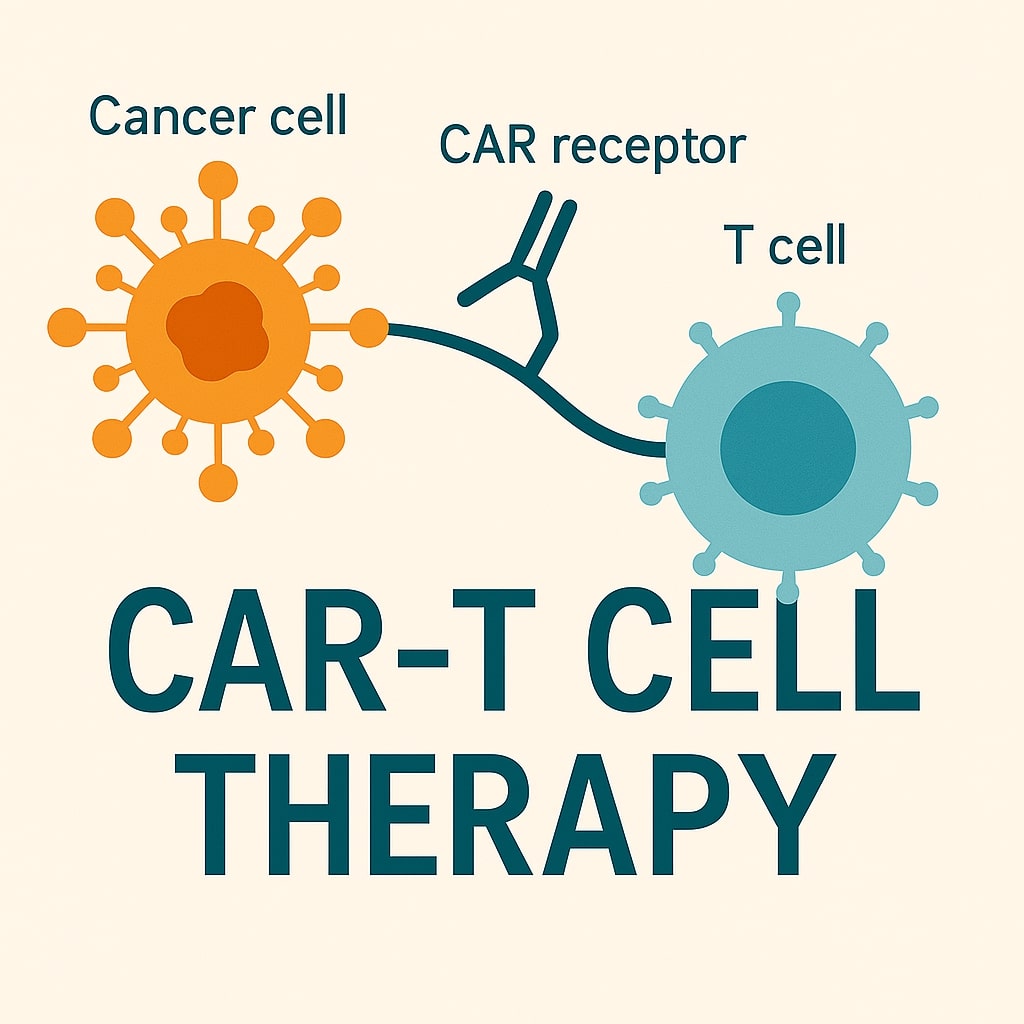

The Pro-Control from Getinge is an adaptable bioprocess controller designed for pilot and production scale bioreactors. Featuring compatibility with DeltaV™, Siemens, and Allen Bradley PLCs, it ensures seamless integration within any facility. Ideal for producing monoclonal antibodies, CAR-T cell therapies, and lab-grown meat, it offers flexible configuration options tailored to specific process requirements. Capable of supporting single-use or sterilizable-in-place systems, Pro-Control manages operations from batch to continuous cultivation efficiently. It boasts a comprehensive set of sensors and actuators, ensuring precise measurement and control, while adhering to cGMP standards. The controller’s design optimizes both single-use and stainless-steel bioreactor applications, facilitating energy-efficient operations and streamlined cleaning.

Benefits

- Enhances operational efficiency with seamless integration and automation.

- Complies with cGMP and 21 CFR part 11 for strict regulatory environments.

- Flexible configuration supports both single-use and sterilizable solutions, adapting to various production needs.

- Improves process accuracy with advanced sensor technology for critical parameter monitoring.

- Streamlines production changeovers, reducing downtime and enhancing productivity.

- Applications

- Media optimization, Microbial cultures, Nutraceuticals, Biopharmaceuticals, Cell and gene therapy, Cellular agriculture

- End products

- Car-t cell therapies, Probiotic cultures, Monoclonal antibodies, Lab-grown meat, Herbal supplements, Optimized cell culture media

- Steps before

- Media preparation, Cell inoculation, Sterilization of containers, Sensor calibration

- Steps after

- Sterilization in place, Batch harvesting, Downstream processing, Cleaning and disinfection

- Input ingredients

- single-use bioreactor ingredients, stainless steel bioreactor ingredients, gas, liquid, biomass, offgas measurements, pressure

- Output ingredients

- bioprocessed products, cell cultures, microbial cultures, optimized media, processed batches, fed-batch outputs, perfusion outputs, continuous cultivation products

- Market info

- Getinge is known for providing innovative healthcare and life sciences products, specializing in medical technology, infection control, surgical workflows, and critical care solutions. They maintain a strong reputation for quality and technological advancement in these sectors.

- PH Sensor

- Mettler Toledo INSUS pH sensor, Traditional Electrochemical

- DO sensor

- Mettler Toledo INSUS DO sensor, Traditional Polarographic

- Temperature Range

- 0-150 °C, accuracy 0.1°C

- Weight Measurement

- Reactor load cells and balances

- Additional I/O

- Up to 8 Analog in and 4 Analog out, Up to 8 Digital in and 8 Digital out

- Gas Control

- Up to 8 MFC's with solenoid valves or up to 8 rotameters with solenoid valves

- Liquid Control

- Up to 4 internal fixed speed pumps, Up to 2 external variable speed pumps

- Impeller Type

- Marine Impeller, Rushton, Marine, Hydrofoil

- Temperature Control

- Lauda Temperature Control Unit (TCU), Cooling and heating jacket via bioreactor wall

- Control Hardware and Software

- Siemens, Allen Bradley, iFix, DeltaV™

- Certifications

- CE certified, GAMP compliant, 21 CFR part 11 compatible

- Communication,SCADA

- Lucullus® PIMS, DeltaV™, iFix

- Getinge OPC server available

- Integration with factory systems

- DeltaV, Siemens PLC, Allen Bradley PLC, iFix

- Automation level

- Fully configurable, PLC / SCADA

- Compatibility

- Single-use and sterilizable-in-place applications

- Process type

- Batch, Fed-Batch, Perfusion, Continuous cultivation

- Flexibility

- Designed on wheels for SUPR, skid for stainless steel

- Control hardware and software platform

- Siemens, Allen Bradley, iFix, DeltaV

- CIP/SIP

- CIP 121°C / SIP 135°C

- 21 CFR part 11 compatible

- Yes

- Machine footprint

- Mobile on wheels or fixed on a skid

- Tank sizes

- 50 to 5, 000 L

- Discharge method

- N/A

- Control panel type

- Siemens or Allen Bradley

- Compact footprint

- Mobile design available

- Control panel type

- Integrated with DeltaV™, Siemens PLC, Allen Bradley PLC

- Integration possibilities

- iFix, DeltaV™, Siemens, Allen Bradley

- Design flexibility

- Wheeled design for SUPR, Skid design for stainless steel bioreactor