Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter dryer that excels in efficient solid-liquid separation, ensuring precise control over filtration, washing, and drying tasks essential for high-stakes applications like active pharmaceutical ingredients and chemical intermediates.

Performs Filtration and Drying of Lab-Scale Batches

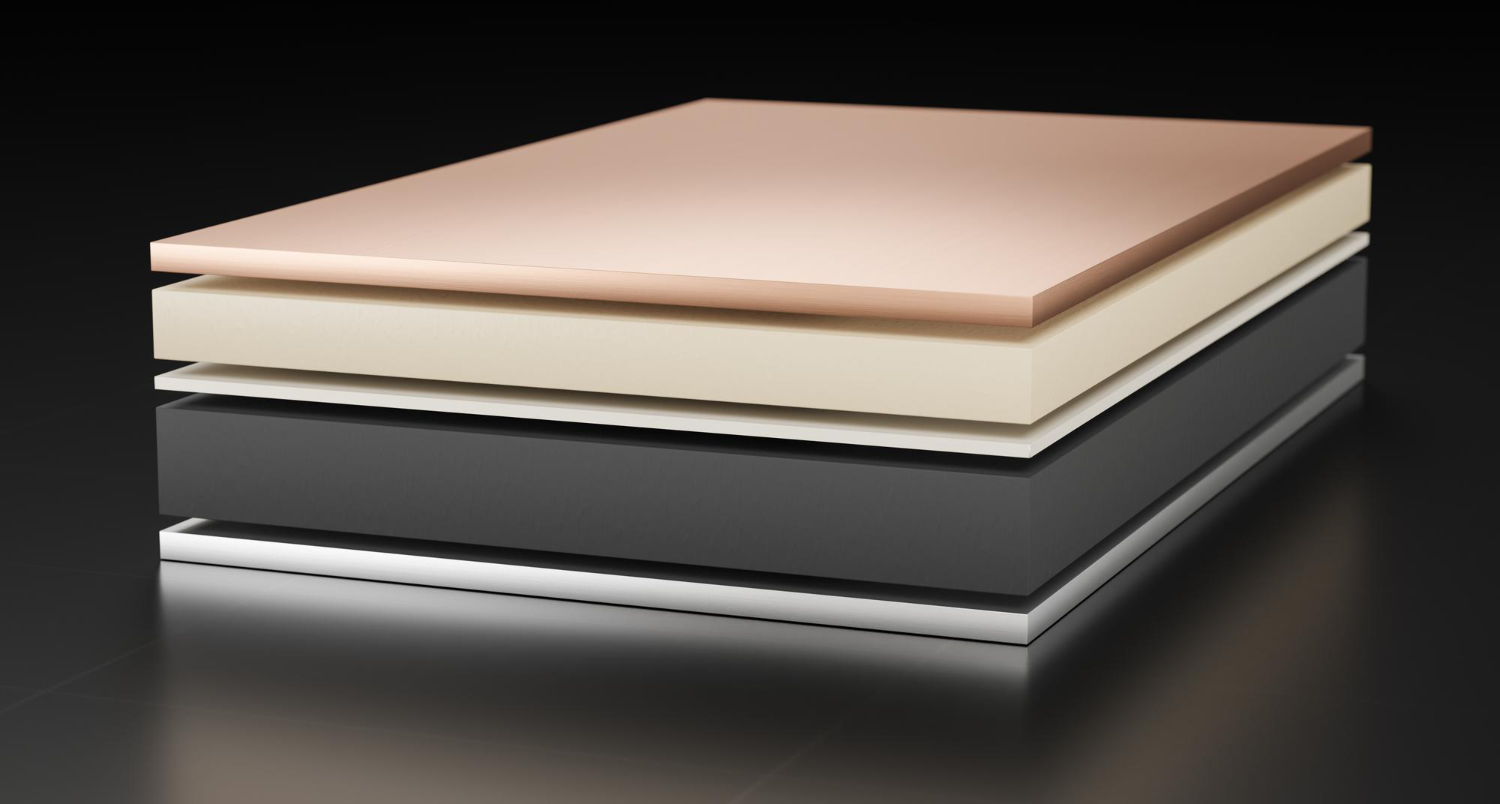

The GFD®Lab, brought to you by Powder Systems Limited (PSL), is a benchtop agitated nutsche filter dryer designed to revolutionize laboratory-scale solid-liquid separation and drying. It combines filtration, washing, re-slurry, vacuum drying, and discharge processes within a single compact unit, making it an essential tool for research institutes, laboratories, and educational institutions. Engineered for flexibility, the GFD®Lab accommodates interchangeable vessels of borosilicate glass, stainless steel, or Alloy-22, ensuring chemical compatibility across various applications such as pharmaceuticals, biotechnology, and chemical process development. The modular design allows easy upgrades to the GFD®Lab PLUS, featuring advanced automation with digital touchscreen controls and real-time data monitoring to enhance process optimization. With its unique filtration basket that facilitates maximal product recovery and adaptability for multi-product use, the GFD®Lab ensures consistent and reproducible results. It supports regulatory needs by meeting Good Laboratory Practices (GLP) and offers seamless integration for scale-up activities, making it ideal for producing antibiotic compounds, APIs, vitamins, and custom chemical compounds.

Benefits

- Enhances product yield with efficient filtration and drying in a single unit.

- Minimizes process variability with automated sequence design and real-time monitoring.

- Increases versatility with easy vessel interchangeability and multi-product capability.

- Supports regulatory compliance by aligning with Good Laboratory Practices (GLP).

- Facilitates safe handling of hazardous substances with optional containment solutions.

- Applications

- Research and development, Fine chemicals, Universities, Nutraceuticals, Pharmaceutical powder, Process engineering, Biopharmaceuticals, Laboratories, Pharmaceuticals

- End products

- Laboratory samples, Antibiotic compounds, Active pharmaceutical ingredients (apis), Chemical intermediates, Vitamin supplements, Clinical research samples, Custom chemical compounds, Graduate lab projects, Protein isolations

- Steps before

- Slurry Filtration, Product Washing, Re-slurry

- Steps after

- Vacuum Drying, Product Sampling, Product Discharge, Batch Reproducibility

- Input ingredients

- slurry, liquid-solids mixture, raw chemicals, materials for filtration, compound slurry

- Output ingredients

- filtered solids, dried product, product cake, collected solids

- Market info

- PSL (Powder Systems Limited) is known for designing and manufacturing advanced containment and process solutions for the pharmaceutical, biopharmaceutical, and chemical industries. They specialize in high-quality filtration, drying, and high containment systems.

- Vessel Material

- Glass / Stainless Steel / Alloy-22

- Heating Jacket

- Yes

- Filtration Area

- 0.002 m² (010 series) / 0.010 m² (050 series)

- Vessel Volume

- 0.3L (010 series) / 2.0L (050 series)

- Typical Product Cake Volume

- 0.03 – 0.10L (010 series) / 0.18 – 0.50L (050 series)

- Frame Dimensions

- 980 x 530 x 330 mm

- Automation

- Manual / Digital Display and Touchscreen (GFD®Lab PLUS)

- Agitator Raise,Lower

- Manual / Automated (GFD®Lab PLUS)

- Working mechanism

- Agitated Nutsche Filter Dryer

- Integrated steps

- Filtration, Drying, Washing, Re-slurry

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / Digital Display, Automation (GFD®Lab PLUS)

- Process control

- Built-in digital interface for process sequence design

- Changeover time

- Quick changeover with removable filter basket

- Corrosive resistance (e.g. acids)

- Alloy 22

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Glass vessel compatibility

- Borosilicate glass

- Stainless steel compatibility

- 316LSS

- Filter mesh material

- Polypropylene, PTFE, 316LSS, Alloy 22

- Heated jacket material

- Stainless steel

- Solid-liquid separation

- Yes

- Multi-product applications

- Supported

- Vessel Material

- Glass, 316LSS, Alloy 22

- Vessel Size

- 010 Series

- Filtration Area

- 010 Series

- Product Cake Volume

- 010 Series

- Frame Dimensions (H x W x D)

- 980 x 530 x 330 mm

- Heated Jacket

- Yes

- Filtration Basket

- Removable

- Control Panel Type

- Digital Display (GFD®Lab PLUS model)

- Control Panel Type

- Digital display with 42 colour HMI touchscreen

- Vessel Material Options

- Glass, 316L Stainless Steel, Alloy 22

- Vessel Size Options

- 010 Series, 050 Series

- Filtration Mesh Material

- Polypropylene, PTFE, 316LSS, Alloy 22

- Base Frame Compatibility

- Modular for vessel size interchange, compatible with all vessel materials

- Agitator Raise,Lower Automation

- Manual (GFD®Lab), Automated (GFD®Lab PLUS)