High pressure homogenizer for cell disruption and nanoemulsions

Achieve precise particle size reduction and enhanced bioavailability in your formulations with advanced high-pressure technology, ensuring consistent product quality and stability across pilot and production scales.

Processes and Encapsulates Liquids at High Pressure

The DeBEE 2000 from Pion is a high-pressure homogenizer designed for diverse applications within the pharmaceutical, biotech, chemical, food, and cannabis industries. It uniquely combines R&D versatility with pilot scale production capabilities, enabling effective processes such as cell disruption, particle size reduction, and nano-encapsulation. This system is ideal for creating protein therapeutics, liposomal encapsulated vitamins, and other intricate formulations, including cannabis-infused beverages. Capable of handling both liquids and slurries, the DeBEE 2000 ensures product consistency and quality with cGMP compliance and SCADA integration for real-time monitoring and control. It features a clean-in-place (CIP) system, simplifying maintenance while ensuring hygiene standards are maintained. With electronic signature compatibility and comprehensive data collection functionalities, this equipment supports stringent regulatory requirements. Pion provides customization options to meet specific production needs, backed by engineering support for seamless integration into your existing production line.

Benefits

- Enhances product stability and bioavailability through precise particle size reduction.

- Facilitates scalability from R&D to larger production without compromising quality.

- Integrates seamlessly into plant systems using SCADA, improving monitoring and control.

- Simplifies cleaning and reduces contamination risk with an efficient CIP system.

- Ensures regulatory compliance with electronic signatures and comprehensive data tracking.

- Applications

- Liposomes, Cannabis-infused beverages, Nutraceuticals, Injectable formulations, Biopharmaceuticals, Emulsions, Transdermal drug delivery, Dispersions, Oral formulations, Pharmaceuticals

- End products

- Cannabis-infused sparkling water, Oral liquid syrups, Skin creams, Liposomal encapsulated vitamins, Lipid-based drug carriers, Protein therapeutics, Vitamin encapsulated nanoemulsions, Injectable vaccinations, Transdermal nicotine patches

- Steps before

- Emulsification, Grinding, Mixing, Suspending

- Steps after

- Sterilization, Packing, Quality Control, Tablet Pressing

- Input ingredients

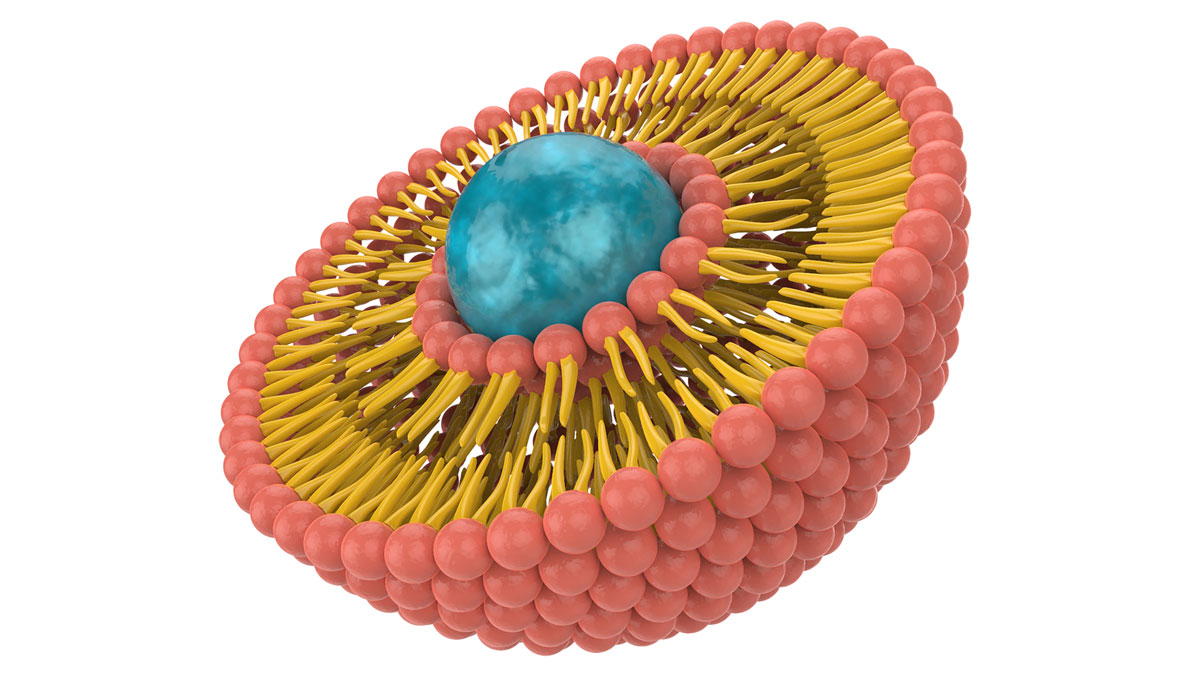

- microemulsions, nanoemulsions, cells, raw materials for dispersions, liposome ingredients

- Output ingredients

- uniform particle size, nano-encapsulated products, cell disrupted materials, stable emulsions, small and uniform liposomes, improved bioavailable formulations

- Market info

- Scalability

- Guaranteed

- Automation

- SCADA (Supervisory Control and Data Acquisition)

- Clean in Place (CIP)

- Yes

- Compliance

- cGMP, CE, CFR 21 Part 11

- Electronic signatures

- Yes

- User management

- Yes

- Audit trail

- Yes

- Data collection

- Yes

- High Pressure Homogenizer

- Yes

- Working mechanism

- High-pressure homogenization

- Integrated steps

- Process customization and scale-up

- CIP/SIP

- CIP available

- Batch vs. continuous operation

- Batch / Pilot scale production

- Automation level

- SCADA

- Energy efficiency

- Efficient high-pressure process

- Cell disruption

- Effective

- Machine footprint

- Pilot scale

- Control panel type

- Electronic / SCADA

- Discharge method

- High-pressure homogenization

- Control panel type

- SCADA

- Integration possibilities

- Plant integration ready

- Customization level

- Advanced process customization