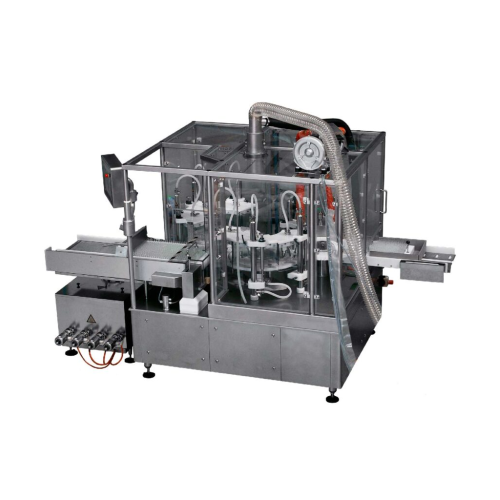

Automatic external washing system for ampoules and vials

Ensure optimal cleanliness of liquid medication containers with a continuous washing system that handles high throughput rates, adaptable for various container sizes and designed for enhanced energy efficiency in rinsing and drying processes.

Washes, Rinses, and Dries Containers

The Type 309 from BAUSCH Advanced Technology Group is a fully automatic, continuous washing machine designed specifically for the external cleaning of ampoules, vials, and bottles, catering to pharmaceutical and biopharmaceutical manufacturers. This machine stands out with its flexible and compact design, enabling customized cleaning cycles and quick size changeovers for containers up to 95 mm in diameter and 180 mm in height. The Type 309 operates with a continuous washing, rinsing, and drying process, ensuring high throughput with a maximum output of 21,000 containers per hour. Its specialized cleaning needles enhance energy efficiency, while sterile hot air blow drying parameters can be adjusted via an operator interface terminal for precise control. The integration of an optional Type 705 recycling station for reconditioning used cleaning agents highlights its cost-effectiveness and eco-friendliness. It also supports smooth integration into existing production lines, addressing the critical need for maintaining container sterility and quality in pharmaceutical manufacturing.

Benefits

- Enhances production efficiency by processing up to 21,000 containers per hour.

- Customizable cleaning cycles optimize resource usage and reduce waste.

- Minimizes downtime with quick size changeovers for varied container dimensions.

- Adjustable drying parameters ensure precise and adaptable cleaning outcomes.

- Optional recycling station reduces operational costs through cleaning agent recovery.

- Applications

- Biopharmaceuticals, Liquid formulations, Nutraceuticals, Pharmaceuticals

- End products

- Ampoules with liquid medications, Vaccine vials, Herbal extract vials, Vitamin supplement bottles

- Steps before

- Filling, Sealing

- Steps after

- Sterilization, Packing, Downstream processing

- Input ingredients

- ampoules, vials, bottles

- Output ingredients

- washed containers, rinsed containers, dried containers, containers in trays, containers to downstream processing

- Market info

- Bausch Group is known for its precision engineering and manufacturing of custom industrial equipment, specializing in engineered-to-order solutions for various industries, prioritizing quality, innovation, and client-specific needs.

- Automation

- Fully automatic

- Capacity

- 21, 000 containers/hr

- Container size

- Up to 95 mm in diameter and 180 mm in height

- Cleaning method

- External wash

- Drying method

- Sterile hot air blow drying

- Energy efficiency

- Improved with specialized cleaning needles

- Adjustability

- Adjustable drying parameters via operator interface

- Customizability

- Flexible and compact design for customized cleaning cycles

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick and easy

- Cleaning method

- External wash

- Energy efficiency

- Improved energy efficiency

- Maximum output

- 21, 000 containers/hr

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Yes

- Machine footprint

- Flexible and compact design

- Container size

- Up to 95 mm diameter, 180 mm height

- Discharge method

- Trays or downstream processing

- Cleaning needle design

- Specialized for energy efficiency

- Control panel type

- Operator interface terminal

- Compact design

- Flexible and compact design allows for customized cleaning cycles

- Size changeover

- Quick and easy size changeovers for different container sizes

- Cleaning cycle customization

- Customized cleaning cycles

- Cleaning needle design

- Specialized cleaning needles for ideal results

- Sterile hot air blow drying

- Parameters adjustable via the operator interface terminal

- Optional recycling station

- Type 705 for reconditioning of used cleaning agents