Automatic carton labeling system

Streamline your packaging line with a high-speed labeling system designed to ensure precise serialization and efficient tracking of cartons, enhancing accuracy and compliance in production processes.

Labels and Serializes Cartons at High Speed

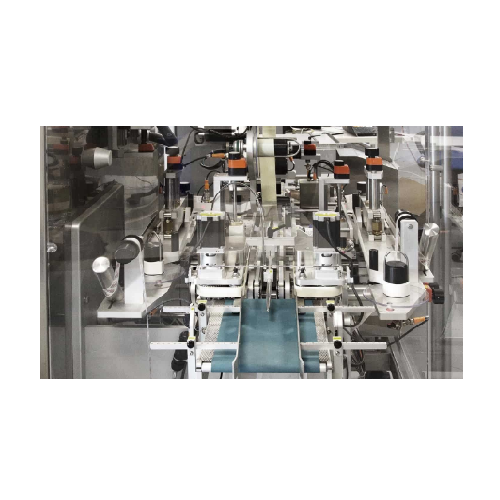

The LM-80V FX Series from Siempharma is a high-speed labeling solution designed to enhance your packaging operations in pharmaceutical, nutraceutical, and cosmetic industries. This machine stands out with its ability to accurately label and serialize carton packages, including medicine blister packs and vitamin carton packaging. Integrating seamlessly into existing production lines, it supports easy installation for track-and-trace capabilities with inkjet, laser printers, and cameras.

The system uses an aluminum chassis with stainless steel panels, offering robust construction and compliance with Industry 4.0 standards. Designed for efficiency, the servo-driven mechanism ensures smooth transportation of cartons without mechanical stress, facilitating uninterrupted labeling processes. With user-friendly touch-screen controls, the LM-80V FX Series simplifies size changeovers and operations, minimizing downtime.

Compliant with CFR21 Part 11 and EU Annex 11, this machine meets stringent serialization requirements, ensuring that all cartons are correctly tracked and documented. Additionally, the option for tamper-evident seal application extends its functionality, making it versatile across multiple applications. Maintenance is streamlined with its cantilever design and open framework, allowing quick access for inspection and service tasks.

Benefits

- Enhances production efficiency with high-speed, non-stop labeling.

- Reduces labor costs through easy, tool-free size changeovers and operations.

- Meets regulatory requirements with GMP-compliant design and serialization capabilities.

- Minimizes downtime with user-friendly touch-screen controls for quick configuration.

- Ensures product safety and integrity with optional tamper-evident seal application.

- Applications

- Nutraceuticals, Cartons, Cosmetics, Pharmaceuticals

- End products

- Herbal supplement bottles, Medicine blister packs, Vitamin carton packaging, Face cream boxes

- Steps before

- Carton filling, Carton sealing

- Steps after

- Package inspection, Carton rejection, Final packing, Distribution

- Input ingredients

- cartons, labels, ink, adhesive

- Output ingredients

- labeled cartons, self-adhesive vignette, tamper evident seals

- Market info

- Machine chassis material

- Aluminum with stainless steel panels

- Safety feature

- Safety guards with interlock switches

- Accessibility

- Cantilever design for easy access

- Carton transportation system

- Tooth belt positive transportation

- Speed

- High-speed, servo driven system

- Automation

- User-friendly size changeover, no tools required

- Track,Trace readiness

- T, T compatible printer and camera

- User interface

- Touch Screen HMI

- Standards compliance

- INDUSTRY 4.0, GMPs, CE rules

- Labeling system

- Electronic adjustment, end-of-label roll check

- Label adhesion

- Polymer roller label adapter

- Coding options

- RFID technology, data matrix, QR code, bar code

- Carton rejection system

- Bin with air blower and sensor for fill level detection

- Labeler adjustment

- 2 guides, vertical and horizontal adjustment

- Printing technology

- Thermal transfer, thermal ink jet, laser

- Tamper evident seals (optional)

- Two heads for seals application

- Automation level

- PLC controlled

- Track-and-trace readiness

- Prearranged for T, T

- Changeover flexibility

- User-friendly, tool-free

- Labeler adjustment

- Electronic and manual, tool-free

- Handling system

- High-speed, servo-driven

- Integration capability

- Inkjet/laser printers and cameras

- System architecture

- Cantilever, open frame

- Safety features

- Safety interlock switches

- Compliance standards

- Industry 4.0, GMPs, CE

- Cleanability

- High due to stainless steel panels

- Corrosive resistance

- Stainless steel

- GMP Compliance

- Yes

- CE marking

- Yes

- EU ANNEX 11

- Ready

- INDUSTRY 4.0 standard

- Compliant

- CFR21 part 11

- Ready

- Machine chassis material

- Aluminum with stainless steel panels

- Safety guard material

- Transparent plastic with safety interlock switches

- Design

- Cantilever design for easy access

- Framework type

- Open frame for easy access and cleaning

- Labeling position adjustment

- Electronic with vertical and horizontal adjustments

- Transportation system

- Tooth belt positive carton transportation

- Adjustable labeler

- 2 guides for labeler adjustment

- Bin for rejected cartons

- Key lock with sensor for maximum fill level detection

- Control panel type

- Touch Screen HMI

- Integration capabilities

- Track-and-tracking units, inkjet, or laser printers and cameras

- Labeling head configuration

- Top labeling head with electronic adjustment

- Installation options

- Two heads for tamper evident seals application

- Label adjustment system

- Vertical and horizontal adjustment via hand wheels

- Data coding options

- RFID, data matrix, QR code, bar code (print, check kit)