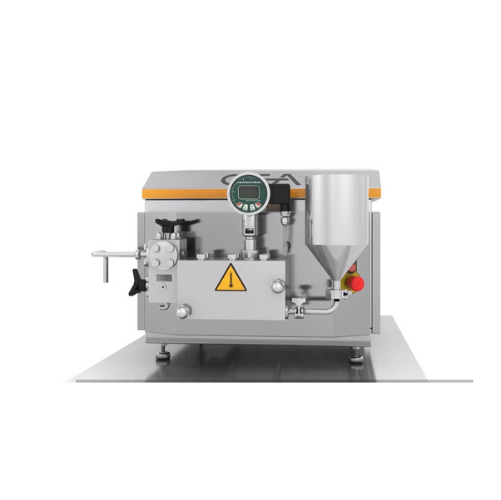

Laboratory homogenizer for small production processes

Optimize your production of nanoemulsions, vitamin suspensions, and more with a table-top homogenizer designed for scalability and efficient handling of sticky or viscous products, ensuring consistent results even in small-scale operations.

Achieves Uniform Particle Size in Lab-Scale Production

The GEA TriplexPanda Lab Homogenizer is a table-top unit designed for laboratory applications requiring precise homogenization, particularly in the development of nanodispersions and nanoemulsions. With its robust three-piston configuration, it supports continuous operation up to 600 bar, making it ideal for complex products such as sticky or viscous substances. This homogenizer facilitates new product development and small-scale production processes, efficiently handling up to 100 liters per hour.

The unit is distinguished by its plug-and-play design, ensuring ease of installation and integration into laboratory settings. Its clean block construction promotes stability and maintenance of uniform flow, essential for reproducible test results in industries like pharmaceuticals, food, and cosmetics. With two models available, offering pressures of up to 400 bar and 600 bar, the TriplexPanda supports scalability from lab testing to larger production setups.

GEA’s engineering support allows for customization to meet specific process requirements, while its energy-efficient operation and potential material options for chemical compatibility further enhance its suitability across a range of demanding applications.

Benefits

- Enhances product quality with consistent particle size reductions in nanoemulsions.

- Supports diverse material handling, including sticky and viscous products, ensuring versatility.

- Increases production efficiency with continuous operation at high pressures.

- Facilitates rapid small-scale production deployment with plug-and-play ease.

- Reduces energy costs through optimized high-pressure homogenization processes.

- Applications

- Food, Beverages, Chemicals, Nanodispersions, Alternative proteins, Nanoemulsions, Cosmetics, Dairy, Pharmaceuticals

- End products

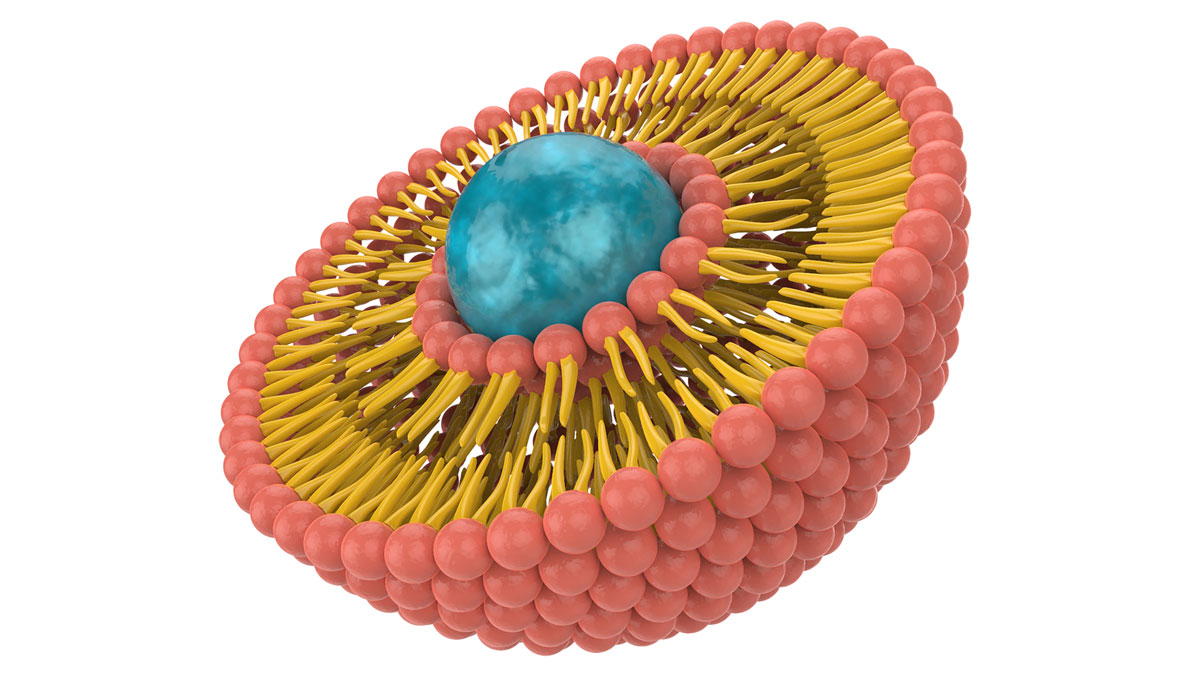

- Fruit juice concentrates, Salad dressings, Vitamin nanoemulsions, Lactose-free milk, Liposomes, Plant-based protein shakes, Anti-aging creams, Specialty polymers, Drug suspensions

- Steps before

- Emulsification, Nanodispersions, Nanoparticles

- Steps after

- Packing, Continuous operation enhancement, Product development analysis

- Input ingredients

- Output ingredients

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Maximum Pressure

- 400 bar

- Maximum Pressure

- 600 bar

- Maximum Flow Rate

- 100 l/h

- Maximum Flow Rate

- 60 l/h

- Scalability

- Guaranteed

- Pumping Flow Stability

- High

- Continuous Operation

- Up to 600 bar

- Scalability

- Guaranteed

- Pumping flow stability

- Stable

- Operation pressure

- Up to 600 bar

- Continuous operation

- Yes

- Automation level

- Plug-in, play

- Product compatibility

- Suitable for sticky and viscous products

- Cleaning method

- Clean block design

- Flow rate

- Up to 100 l/h

- Batch vs. continuous operation

- Batch/Small production

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Suitable for difficult, sticky, and viscous products

- Homogenization effect

- Enhanced performance for laboratory tests and small production processes

- Machine footprint

- Table-top

- Design

- Clean block

- Compact footprint

- Yes

- Control panel type

- Plug-in, Play

- Discharge method

- Pumping flow

- Scalability

- Guaranteed

- Flow stability

- Stable pumping flow

- Design type

- Clean block design

- Operation pressure

- Up to 600 bar

- Operation continuity

- Continuous operation

- Model options

- Various with full list of options