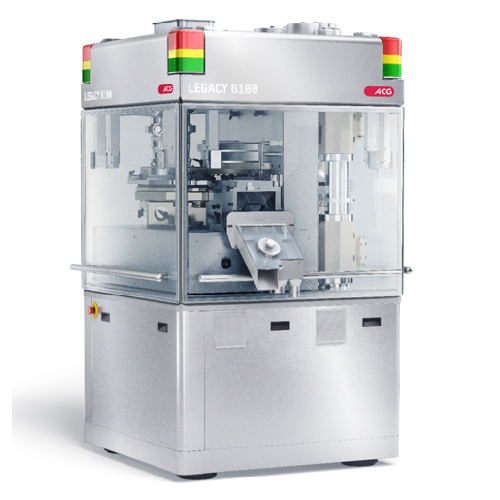

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tablet quality and reliable output, even with challenging formulations like abrasive or poor-flow powders.

Compresses Tablets with Precision and Speed

ACG’s LEGACY 6100 is a single-rotary tablet compression machine designed to meet the rigorous demands of pharmaceutical and nutraceutical production. It excels in compressing monolayer tablets and Multiple-Unit Particulate Systems (MUPS), reducing segregation and enhancing tablet uniformity. The machine accommodates abrasive, corrosive, and poor-flow ingredients, providing consistent tablet quality with minimal crushing. It features an interchangeable turret design enabling rapid changeovers, optimizing throughput up to 402,000 tablets per hour. The largest feeder coverage in its class facilitates precise dosing, while the advanced PARAMOUNT turret design boosts output by 27%. With a 290 mm compaction roller, the LEGACY 6100 ensures effective compression through extended dwell time. Fully automated, it integrates seamlessly into existing lines with precise sorting and sampling capabilities, ensuring tablets meet all specification criteria. Built with GMP compliance in mind, it supports efficient cleaning and maintenance routines.

Benefits

- Enhances production efficiency by increasing tablet output up to 27%.

- Ensures consistent tablet uniformity, reducing product variability and waste.

- Minimizes downtime with quick turret changeovers for diverse tablet shapes.

- Provides accurate dosing for reliable high-speed operations.

- Complies with GMP standards, ensuring quality and safety in production.

- Applications

- Monolayer tablets, Nutraceuticals, Granules, Mups, Pharmaceuticals

- End products

- Ibuprofen tablets, Calcium carbonate tablets, Vitamin d tablets, Protein powder tablets, Fish oil softgels, Probiotic capsules, Herbal supplement tablets, Multivitamin supplements, Cough suppressant tablets, Aspirin tablets

- Steps before

- Granulation, Blending, Mixing

- Steps after

- Coating, Blister packaging, Inspection, Cartoning

- Input ingredients

- pharmaceutical granules, nutraceutical granules, MUPS, powder, abrasive ingredients, corrosive ingredients, challenging formulations

- Output ingredients

- monolayer tablets, tablets of all shapes and sizes, uniform tablets, tablets with dependable dissolution profiles

- Market info

- ACG World is known for its expertise in manufacturing pharmaceutical and nutraceutical processing and packaging machinery, offering innovative equipment solutions and maintaining a strong reputation for quality and reliability in the global market.

- Punch type

- DB, BBB, BBS

- Punch stations

- 37, 45, 61, 67

- Output

- 222, 000 to 402, 000 tablets/hr

- Maximum tablet diameter

- 11 mm to 25 mm

- Feeder coverage

- Up to 9 feeders

- Compaction roller diameter

- 290 mm

- Increase in output

- Up to 27%

- Compression Operation Type

- Single Rotary

- Automation Level

- Fully Automated

- Changeover Efficiency

- Quick and Easy

- Sorting and Sampling Mechanism

- Precise Single Sorting

- Dosing Accuracy

- High-speed Production

- Tablet Uniformity

- Improved Tablet Uniformity

- Feeder Coverage Capacity

- Up to 9 Feeders

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Turret design

- Interchangeable

- Feeder coverage

- Up to 9 feeders

- Compaction rollers diameter

- 290 mm

- Control panel type

- Fully Automated

- Interchangeable turret design

- Quick, easy changeover

- Specialised kits for MUPS

- Abrasive/corrosive formulations

- Control panel type

- Fully automated

- Feeder coverage

- Up to 9 feeders