Single-use transfer and filling solutions in barrier isolated filling lines

Ensure sterile, high-volume liquid transfer and final filling in pharmaceutical production with solutions designed to prevent microbial contamination and optimize process efficiency.

Facilitates Sterile Liquid and Component Transfers

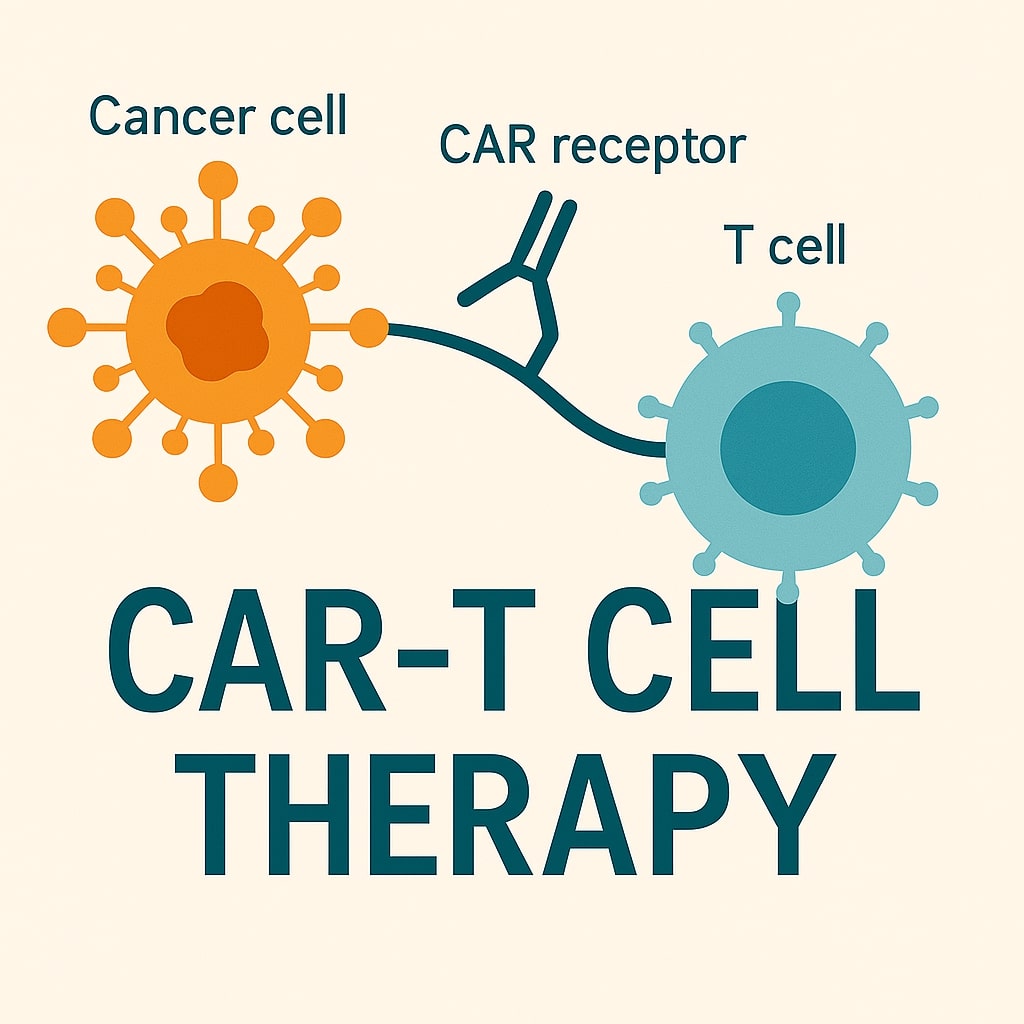

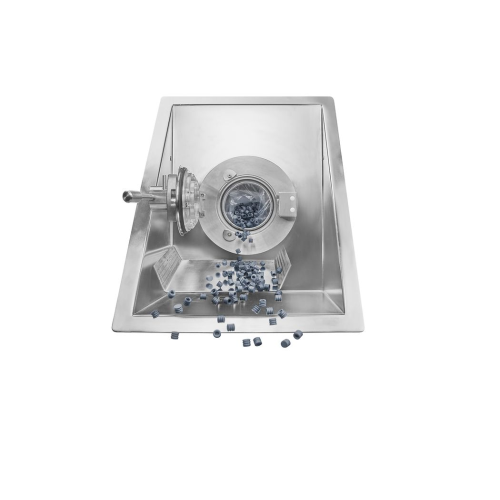

Biosafe® and SART System™ from Sartorius offer a cutting-edge solution for aseptic transfer processes in pharmaceutical and biotech production lines. These systems provide unique capabilities for securely facilitating sterile transfers of liquid formulations, components, and drug products through isolators, minimizing contamination risks. Ideal for applications like vaccine production and cell and gene therapies, they maintain high-integrity transfers essential for injectable biologics and mRNA lipid nanoparticles. The Biosafe® system’s magnetic connection ensures a seamless and contamination-free process, while the SART System™ minimizes footprint and optimizes ergonomic efficiency in transfer operations. Capable of modular configuration, these systems integrate seamlessly with existing operations, simplifying setup and reducing downtime. Featuring single-use options, they eliminate the need for cleaning and sterilization, conforming to GMP and FDA standards for regulatory compliance.

Benefits

- Enhances patient safety by minimizing microbial contamination risks.

- Streamlines operations with quick, contamination-free setup through single-use components.

- Integrates effortlessly into existing systems, optimizing space and ergonomics.

- Meets strict regulatory standards, ensuring GMP and FDA compliance.

- Reduces operational costs with simplified maintenance from single-use design.

- Applications

- Liquid formulations, Vaccines, Pharmaceutical tablets, Nutraceuticals, Monoclonal antibodies, Mrna production, Regenerative medicine, Bioconjugation, Biopharmaceuticals, Cell and gene therapy, Pharmaceutical powders

- End products

- Mrna lipid nanoparticles, Monoclonal antibody vials, Car-t cell therapies, Stem cell therapy solutions, Lyophilized injectable compounds, Injectable biologics, Covid-19 vaccines, Nutraceutical pills, Soft gel capsules, Ophthalmic solutions, Bispecific antibodies, Liquid oral syrups, Tablet blisters, Influenza vaccines

- Steps before

- Aseptic preparation, Component transfer, Sterilization, Assembly of sterile fluid path

- Steps after

- Sealing, Final inspection, Labeling, Packaging

- Input ingredients

- stoppers, plungers, aluminum seals, primary packaging components, sterile fluid

- Output ingredients

- filled syringes, filled vials, final drug product

- Market info

- Sartorius AG is renowned for manufacturing high-precision laboratory and bioprocess equipment. They specialize in filtration, fermentation, and cell cultivation systems, known for their innovation and reliability in the pharmaceutical and biotech industries.

- Automation

- Single-use technology

- Capacity

- Varies based on batch volume

- Filling method

- Single-use and ready to use transfer

- Filling volume

- Customizable to application

- Filling accuracy

- High assurance of supply

- Filtration system

- Sterile filter transfer set

- Material transfer efficiency

- Improved with Biosafe® bottle-shaped bags

- Port size

- Biosafe®110

- Design

- SART System™ for reduced footprint

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Aseptic transfer

- Secured by the Biosafe® RAFT system

- Final filling setup

- Simplified by Octoplus FF®

- Footprint

- Compact / Smaller footprint

- Bag shape

- Bottle-shaped

- Bag type

- Single-use / Ready to Use / Ready to Sterilize / Ready to Fill

- Bag size

- Customizable

- Discharge method

- Tubing transfer through a port

- Automation level

- Reduces human intervention

- Port Types

- Biosafe®110, SART System™

- Bag Options

- RTU, RTS, RTF

- Configuration

- Bottle-shaped bags, Flexsafe®2D bags

- Connector Types

- Gammasart ATD™ connector

- Systems and Components

- Octoplus FF® configurations

- Material Transfer Efficiency

- Bottle-shape 2G design