Drying systems for bioethanol production

Optimize your bioethanol production with advanced evaporation and drying equipment, ensuring efficient conversion of feedstocks into high-value end products like bioethanol, high-protein feeds, and bio-based chemicals.

Processes Bioethanol and High-Protein Feed Products

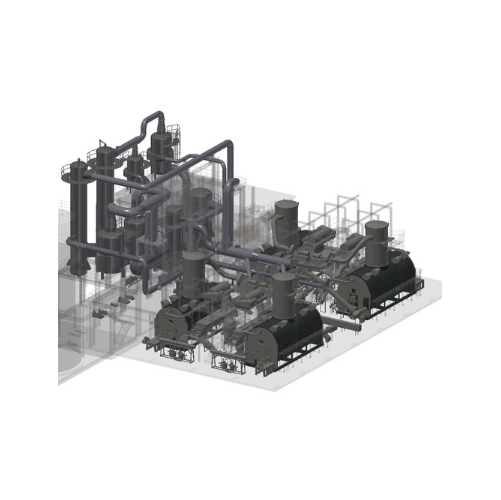

The Bioethanol Production and Processing Systems from VetterTec GmbH are engineered to support first and second-generation ethanol plants. These systems integrate stillage evaporators, high-protein animal feed dryers, and sophisticated mixing systems to optimize biofuel and protein production. Employing a closed air system to minimize emissions, they ensure energy efficiency with advanced evaporators and dryers selecting from VetterTec’s extensive range of technologies. Applications span bioethanol, DDGS, yeast extract, and plant-based protein concentrates, with a capacity for large-scale, continuous processing. Built for automation, these systems align with operations in agrifood, starch, grain, and chemical industries, and offer easy integration with your existing production line. Available in materials designed for corrosion resistance, they meet industry standards and allow for tailored configurations to suit production needs.

Benefits

- Maximizes conversion efficiency, enhancing yield for ethanol and high-protein feeds.

- Reduces operational costs through energy recovery and minimized emissions.

- Integrates seamlessly into existing systems, enhancing overall process efficiency.

- Supports continuous operation, reducing the need for manual intervention.

- Offers flexibility with customizable configurations to meet specific production requirements.

- Applications

- Protein production, Animal feed, Starch products, Ethanol, Nutraceuticals, Chemical products, Food ingredients, Biofuel

- End products

- Bioethanol, Gluten powder, Plant-based protein concentrates, Yeast extract, Ethanol fuel, Bio-based chemicals, High-protein animal feeds, Ddgs (dried distillers grains with solubles), Corn syrup

- Steps before

- Corn Wet Milling, Stillage Evaporation, Mechanical Dewatering

- Steps after

- High Protein Feed Drying, Feed Pelletizing, Yeast Spray Drying, Gluten Drying, Pneumatic Conveying, Intermediate Storage

- Input ingredients

- stillage, gluten, yeast, grain

- Output ingredients

- bioethanol, high protein animal feed, DDGS, feed pellets, yeast spray dried product, gluten dried product

- Market info

- VetterTec is known for engineering and manufacturing industrial drying and dewatering solutions, particularly for the food, brewery, chemical, and environmental industries, leveraging extensive experience in delivering efficient and reliable tailored systems.

- Stillage evaporator capacity

- Varies by plant

- High protein feed (DDGS) dryers

- Variable output capacity

- Yeast spray drying capacity

- Depends on application

- Gluten drying efficiency

- High efficiency

- Pneumatic conveying system speed

- Adjustable

- Stillage evaporator energy recovery

- Integrated

- Emission control system

- Closed air system

- Syrup utilization

- Highest in class

- Automation

- Advanced process control

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- HMI / Touchscreen