Compact fermentor for research and scale-up studies

Optimize your bioprocess development with a desktop fermentor that offers precise temperature control, versatile stirring capabilities, and comprehensive data logging, ideal for scaling up experimental findings in small-scale and pilot production environments.

Cultivates and Optimizes Microbial and Cell Cultures

The Desk Top Fermentor from Marubishi Bioengineering offers a versatile solution for biotech and pharmaceutical applications, accommodating various cell types from microbes to mammalian cells. Its unique hollowed bottom end plate facilitates accurate temperature control through mild heating and rapid cooling, ensuring optimal fermentation conditions. With interchangeable vessel sizes up to 10 liters, it provides full-scale fermentation capabilities in a compact form. Tailored for precision, it includes top or bottom entry driving systems and multiple stirring impellers to cater to different culture processes, such as aerobic and anaerobic fermentations. Ideal for producing biologics, vaccines, and enzyme supplements, this fermentor features a user-friendly interface, integration with bioprocess controllers, and options for data logging via USB. The equipment is energy-efficient, utilizing mass flow controllers for aeration and precise agitation systems. Available in materials that resist corrosion, it is suitable for harsh processing environments. The fermentor conforms to industry standards for quality and safety, offering seamless integration into existing production lines and easing operational challenges through its modular design and easy maintenance. Customizable features include pressure handling up to 0.2MPa(G) and optional automation enhancements, ensuring optimal performance across diverse fermentation applications.

Benefits

- Ensures efficient fermentation with precise temperature and aeration control, improving culture yield and quality.

- Minimizes space requirements while maintaining full-scale fermentor functions, ideal for labs with limited space.

- Offers flexibility in culture conditions, supporting both aerobic and anaerobic processes for diverse bioproduction needs.

- Reduces setup and operational time through user-friendly interfaces and automated data logging, increasing productivity.

- Enhances process reliability with modular design and compatibility with industry-standard bioprocess controllers.

- Applications

- Microbial cultures, Algae cultures, Fine chemicals, Cell cultures, Nutraceuticals, Biopharmaceuticals, Enzymes, Pharmaceuticals

- End products

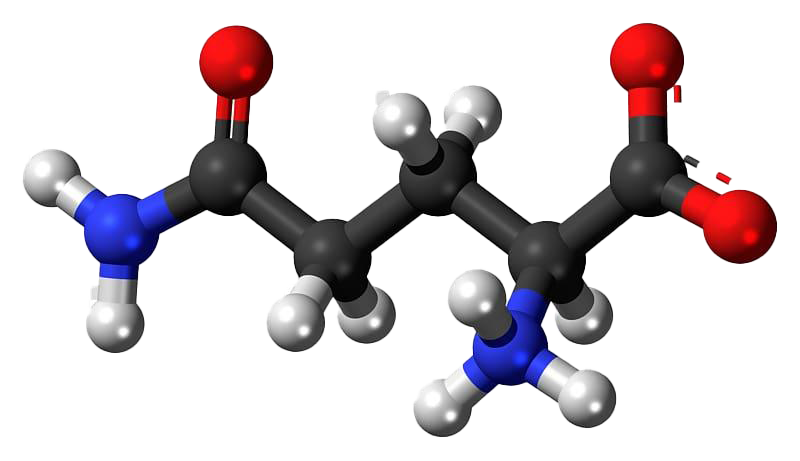

- Biologics, Amino acids, Ethanol, Vaccines, Probiotic cultures, Insulin, Monoclonal antibodies, Bioplastics, Biopesticides, Yeast extracts, Enzyme supplements, Spirulina powders, Chlorella supplements, Recombinant proteins

- Steps before

- Sterilization, Preparation of culture media, Inoculation

- Steps after

- Downstream processing, Purification, Data analysis

- Input ingredients

- aerobic microbes, anaerobes, ultra thermophilic bacteria, micro algae, mammalian suspension cells, phototropic bacteria, cyanobacteria, blue algae, Euglena, Chlorella vulgaris, Botryococcus, Aurantiochytrium, Koji, rice mold, soy beans

- Output ingredients

- cultured cells, fermented products, biomass, gas outputs (O2, CO2)

- Market info

- Marubishi Bioengineering is known for its expertise in manufacturing high-quality bioreactors and fermentation systems for the biotechnology and pharmaceutical industries, reputed for their precision-engineering and customization to meet specific client requirements.

- Vessel Capacity

- 0.5 to 10 liters

- Temperature Control

- Mild heating and rapid cooling

- Driving System

- Top or bottom entry

- Stirring Impeller Type

- Various types available

- Process Compatibility

- Aerobic and anaerobic

- Channel Measurement

- Up to 12 channels (Bioneer-Neo series)

- Touch Panel Size

- 7-inch (Bioneer-Neo), 5.7-inch (Bioneer)

- Automation

- Manual and auto modes available

- Pressure Range

- Up to 0.2 MPa(G), over if requested

- Light Source Options

- White LED, CCFL, fluorescent

- ORP Measurement

- Included in Bioneer-Neo

- Data Saving

- USB port for CSV format

- Device Width

- 188mm (Bioneer-Neo)

- Intermittent Agitation

- For solid state culture fermentor

- Humidity Control

- Spray sterile water in solid state fermentor

- Fermentor type

- Desktop / Compact

- Temperature control

- Mild heating / Rapid cooling

- Driving system

- Top or Bottom entry

- Stirring impeller type

- Various types available

- Aeration type

- Aerobic / Anaerobic

- Oxygen transfer rate

- High efficiency

- Culture process compatibility

- Aerobic microbes / Anaerobes / Algae / Mammalian cells

- Biological compatibility

- Compatible with various cells such as anaerobes, ultra thermophilic bacteria, microalgae, mammalian suspension cells

- Cleanability

- Autoclavable vessels up to 10 liters

- Corrosive resistance (e.g. acids)

- Suitable for diverse and potentially corrosive bioprocess liquids

- Machine Footprint

- Compact

- Vessel Size

- 0.5 to 10 liters

- Entry System

- Top or Bottom Entry

- Impeller Type

- Various for different culture processes

- Heating/Cooling

- Hollowed Bottom End Plate for Mild Heating/Rapid Cooling

- Control Panel Type

- 7-inch or 5.7-inch Color Graphic Touch Panel

- Control panel type

- 7-inch wide color graphic touch panel

- Control panel type

- 5.7 inch color touch panel

- Entry driving system

- Top or bottom entry

- Stirring impeller types

- Various types available

- Vessel volume

- 0.5 to 10 liters

- Feeding control mode

- Various modes available

- Measurement channels

- Max. 8 or 12 channels

- Integration possibilities

- USB port/RS232c serial port for PC connection

- Culture process

- Aerobic, anaerobes, ultra thermophilic bacteria, etc.