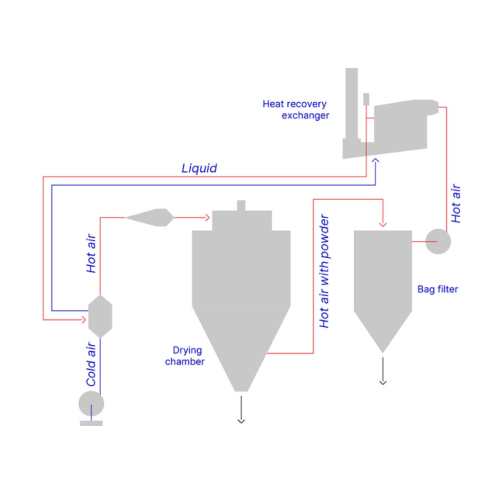

Heat recovery system for spray drying plants

Enhance your spray drying efficiency with a heat recovery system that captures and reuses waste heat, reducing energy consumption and cutting carbon emissions. Experience seamless integration and CIP compatibility to streamline operations and boost sustainability across your production line.

Captures and Reuses Waste Heat for Efficiency

The GEA Heat Recovery System is a pivotal solution for optimizing energy efficiency in spray drying operations within the food, beverage, pharmaceutical, and chemical sectors. This system captures waste heat from exhaust air via a water-based heat exchanger, significantly reducing reliance on fossil fuels by preheating inlet air. Supporting continuous and automated processes, it offers up to a 15% decrease in energy consumption and CO2 emissions. Designed for easy integration, this system incorporates CIP compatibility for fast, efficient cleaning, and requires minimal maintenance. Custom-configured to suit both new and existing spray drying plants, it is particularly effective in producing milk powder, pharmaceutical powders, and other spray-dried products. GEA provides comprehensive engineering support to ensure seamless installation and operation, while their AddCool high temperature heat pump technology can further enhance energy savings. With robust construction and advanced automation, the system also supports GEA OptiPartner for enhanced process control and optimization.

Benefits

- Lowers energy consumption and carbon footprint by up to 15%.

- Minimizes operational downtime with hands-free, CIP-compatible cleaning.

- Reduces fossil fuel use, enhancing environmental sustainability.

- Frees up operator time with automated process control.

- Supports diverse industry applications with customizable configurations.

- Applications

- Food, Chemicals, Gas and energy, Beverage, Dairy farming, Oil, Environment, Dairy, Pharmaceutical

- End products

- Dehydrated fruit juices, Detergent powders, Baby formula, Spray-dried coffee, Milk powder, Whey protein concentrate, Nutritional supplements, Biofuel components, Chemical catalysts, Pharmaceutical powders, Lactose

- Steps before

- Preheating, Air Heating, Spray Drying Preparation

- Steps after

- Cooling, Packing, Powder Handling

- Input ingredients

- fossil fuels, spray dryer air, exhaust air

- Output ingredients

- heated air, reduced CO2, waste heat energy

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Energy Reduction

- Up to 15%

- Temperature Increase at Intake

- 20 - 40°C

- Carbon Footprint Reduction

- Up to 15%

- CIP Compatibility

- Yes

- Maintenance Frequency

- Annual Inspection

- Automation Level

- Hands-free Operation

- Heating System

- Water-based Heat Exchanger

- Process Stability Improvement

- 80%

- Productivity Increase

- 7%

- Efficiency Gain on Energy Use

- 5-10%

- Working mechanism

- Water-based heat exchanger

- Integrated steps

- Preheats inlet air using exhaust waste heat

- CIP principles

- CIP compatible for fast, thorough cleaning

- Batch vs. continuous operation

- Continuous operation

- Energy efficiency

- Reduces energy by up to 15%

- Automation level

- Hands-free operation

- Down time reduction

- Automated CIP minimizes down time

- Fossil fuel reduction

- Up to 15% reduction in usage

- Carbon footprint reduction

- Reduces CO2 production by up to 15%

- Cleanability

- CIP compatible

- Fossil fuel replacement potential

- Potential to shut off fossil fuel-fired boilers with AddCool integration

- Heat exchanger configuration

- Custom-configured to plant

- Integration possibilities

- Compatible with existing spray drying systems

- Control system integration

- GEA OptiPartner platform

- CIP compatibility

- Yes, automated CIP

- Maintenance requirements

- Minimal, yearly inspection