Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by ensuring precise mixing and homogenization, essential for achieving consistent quality in biopharmaceuticals and cosmetics.

Processes and Optimizes Liquid Formulations

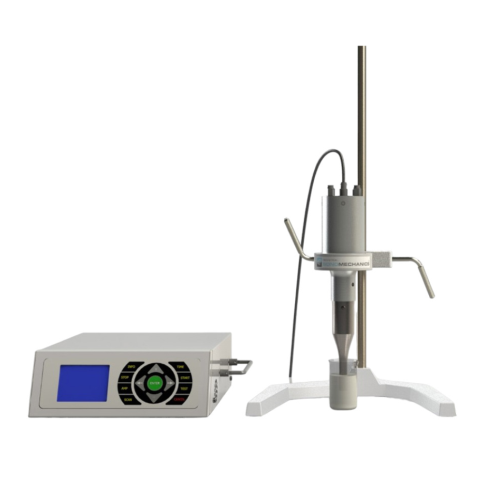

The LSP-600 ultrasonic liquid processor from Kinematica AG is designed for feasibility testing and procedure optimization in R&D and laboratory settings. This processor utilizes a robust 600 W ultrasonic generator paired with an air-cooled transducer, facilitating efficient mixing and homogenization. It’s particularly suited for applications in biopharmaceuticals, fine chemicals, nutraceuticals, cosmetics, and food industries, aiding in the formulation of vaccines, APIs, protein supplements, and more. Capable of handling up to 2 L of liquid, the LSP-600 is equipped with a full-wave Barbell Horn® and a medium-duty support stand for stable operation. Optional features like a flow-through reactor chamber and peristaltic pump enhance versatility. While not automated in standard form, it integrates smoothly into pilot and bench-top operations, offering precision and consistency. Constructed with durable materials, this equipment ensures reliable performance across various operational conditions, supporting stringent compliance and industry standards.

Benefits

- Enhances process efficiency with precise ultrasonic homogenization.

- Supports diverse applications, from pharmaceutical APIs to flavored syrups.

- Facilitates rapid feasibility testing and process optimization in lab settings.

- Offers versatile integration into pilot and continuous operations.

- Adaptable with various optional accessories for tailored applications.

- Applications

- Food, Liquid formulations, Fine chemicals, Pharmaceutical tablets, Nutraceuticals, Cosmetics, Biopharmaceuticals, Life science

- End products

- Flavored syrups, Vaccines, Effervescent tablets, Active pharmaceutical ingredients (apis), Moisturizers, Herbal extracts, Protein supplements, Nutritional drinks, Dna/rna extracts, Anti-aging creams

- Steps before

- Emulsification, Mixing, Pre-processing, Formulation preparation

- Steps after

- Procedure optimization, Sterilization, Filling, Packaging

- Input ingredients

- Output ingredients

- Market info

- Operation Time

- Up to 1 hour continuous

- Liquid Volume Capacity

- Up to 2 L

- Power Output

- 600 W

- Working mechanism

- Ultrasonic liquid processing

- Operation duration

- Up to 1 hour continuous

- Volume capacity

- Up to 2 L

- Heat management

- Air-cooled transducer

- Automation level

- Manual

- Batch vs. continuous operation

- Batch

- Sound management

- Noise reduction ear muffs

- Modular setup

- Optional accessories available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Tank size

- 2 L

- Operational duration

- Up to 1 hour

- Sonicator power

- 600 W

- Integration possibilities

- Flow-through reactor chamber

- Support stand type

- Medium-duty

- Cooling method

- Air-cooled transducer