Serialization system for printing and verifying carton codes

Ensure accurate serialization with high-speed printing and verification on multiple carton sides, offering seamless integration into existing production lines while maintaining data integrity and compliance.

Serializes, Verifies, and Inspects Packaging

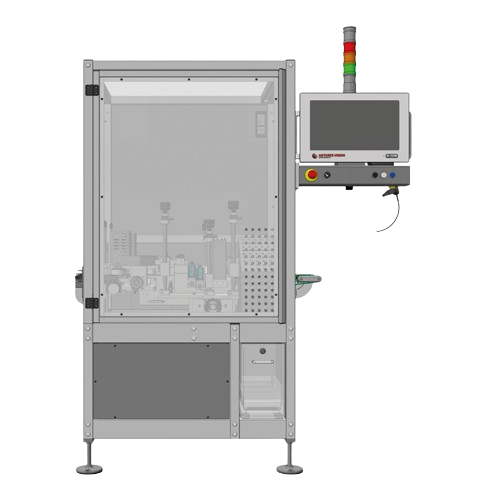

The Print & Check Advanced VM0200 from Antares Vision Group serves as a sophisticated, standalone unit designed for precise serialization, marking, and verification of carton packaging in the pharmaceutical and consumer goods industries. This system is capable of printing on up to three sides of a carton using both laser and Thermal Inkjet (TIJ) technologies, ensuring flexibility and quality with a resolution of up to 600 dpi. With a labeling option, the VM0200 also features a dedicated camera and software for label inspection, verifying position, integrity, and data accuracy. Operating at speeds of up to 400 pieces per minute, this machine seamlessly integrates into both in-line and off-line operations, making it ideal for high-volume environments. The VM0200 supports various carton sizes and is equipped with up to three cameras for comprehensive track & trace capabilities, ensuring compliance with serialization requirements. It’s particularly suited for packaging lines in pharmaceuticals, nutraceuticals, and cosmetics, handling products like pharmaceutical tablets, skincare cream jars, and cosmetic cartons.

Benefits

- Ensures high data integrity and compliance with serialization regulations, reducing the risk of counterfeit products.

- Enhances production efficiency with high-speed operation, capable of processing up to 400 items per minute.

- Offers flexible integration with both in-line and off-line packaging systems, adapting to various production needs.

- Minimizes errors through advanced label inspection and verification, ensuring correct labeling and packaging quality.

- Reduces downtime with a user-friendly interface that simplifies equipment settings and operations.

- Applications

- Nutraceuticals, Consumer goods, Cosmetics, Packaging industry, Pharmaceuticals

- End products

- Toothpaste tubes, Shampoo bottles, Pharmaceutical tablets, Tea boxes, Over-the-counter medicine boxes, Blister packs, Skincare cream jars, Cereal boxes, Vitamin bottles, Cosmetic cartons, Dietary supplements

- Steps before

- Carton Preparation, Label Design, Data Upload

- Steps after

- Packing, Quality Control, Shipping

- Input ingredients

- carton boxes, labels, ink cartridges

- Output ingredients

- printed carton boxes, verified labels, serialization data

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- up to 400 pcs/min

- Working Height

- 800-1000 mm

- Conveyor Length

- 1120 mm

- Standard Belt Pitch

- 150 mm

- Standard Carton Size (mm)

- A = 35-120, B = 15-140, C = 45-210

- Printable Sides

- 3

- Printing Heads

- Up to 4

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical

- Up to grade A

- Number of Cameras for Inspection

- Up to 3

- Printing sides

- Up to 3 sides

- Printing speed

- Up to 400 pcs/min

- Verification system

- Inline / Off-line

- Labeling and inspection

- Automated camera, software inspection

- HMI control

- Single HMI for all functions

- Serialization

- Automatic marking, recording, verification

- Working height

- 800-1000 mm

- Conveyor length

- 1120 mm

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 1120 mm conveyor length, 800-1000 mm working height

- Carton size

- A = 35-120 mm / B = 15-140 mm / C = 45-210 mm

- Standard belt pitch

- 150 mm

- Control panel type

- Single HMI

- Printing Options

- Laser printer and TIJ

- Labeling System

- Top labeling system with inspection camera

- Integration Possibilities

- Serialization data management and verification