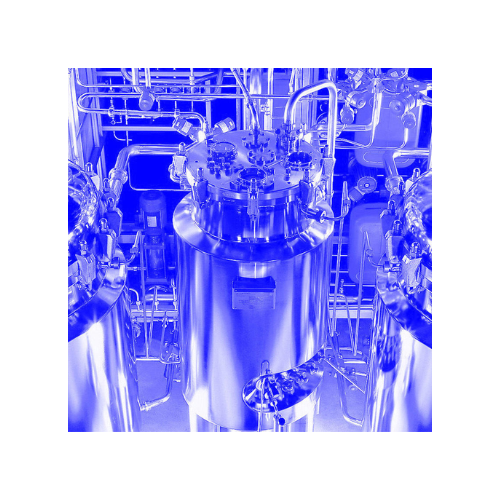

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing and sterile transfer, crucial for maintaining ideal conditions in biopharmaceutical production and enhancing product quality.

Prepares and Doses Media and Buffers

The Media / Buffer Prep system from Bioengineering is essential for biopharmaceutical and pharmaceutical production lines, optimizing the preparation and dosing of media and buffers. Featuring sterilizable stainless-steel vessels ranging from 30 to 20,000 liters, it ensures sterile, dust-free transfer and dissolution of powders using the Cup-Hermann system. This equipment is tailored for operations from manual to full automation, integrating seamlessly with upstream and downstream processes in labs, R&D facilities, and production plants. It supports applications including recombinant protein production, monoclonal antibodies, and vaccine formulations. The system is PLC-controlled, enabling precise level, weight, and pH control, and integrates with CIP systems for efficient cleaning. Built to meet GMP standards, it offers customizable configurations to match unique process requirements, promising reliability and high product quality.

Benefits

- Ensures high product quality by maintaining sterile, dust-free media and buffer preparation.

- Increases operational efficiency with customizable automation from manual to full integration.

- Reduces manual intervention, enhancing safety and consistency in buffer dosing.

- Simplifies cleaning and maintenance with integrated CIP capabilities.

- Supports diverse applications across biotech, pharmaceutical, and food industries.

- Applications

- Microbial fermentation media, Liquid formulations, Nutraceuticals, Pharmaceutical powder, Cell culture media, Biopharmaceuticals

- End products

- Probiotic cultures, Monoclonal antibodies, Injectable solutions, Vaccine formulations, Oral liquid solutions, Protein supplements, Effervescent tablets, Recombinant proteins

- Steps before

- Powder Dissolution, Infeed of Ultra-Pure Water, Media and Buffer Preparation

- Steps after

- Sterile Transfer, Feeding into Reactors, Downstream Processing

- Input ingredients

- ultra-pure water, powder, media, buffers

- Output ingredients

- culture medium, correction medium, fed-batch medium, buffer

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Vessel Capacity

- 30–20, 000 liters

- Container Capacity

- 10–50 liters

- Glass Bottle Capacity

- 0.5–10 liters

- Powder Feeding System

- Cup-Hermann powder transfer

- Infeed Method

- Drum-lift or vacuum-feed systems

- Dissolution Method

- Stirrers or circulation pumps

- Transfer System

- On/off pumps or pressure-operated metering systems

- Control System

- Level, weight, pH control

- Sterilization

- Full integration into CIP system

- Automation

- Manual operation or complete automation

- Filling Method

- Dust-free powder addition

- Storage Tank Integration

- Solutions fed into reactors or vessels

- Application

- Culture medium, correction medium, fed-batch medium, buffer

- Automation level

- Manual / Complete automation

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Dust-free handling

- Implemented / Not implemented

- Sterile transfer capabilities

- Yes / No

- Level control

- Yes / No

- Weight control

- Yes / No

- PH control

- Yes / No

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Vessel Capacity

- 30 to 20, 000 liters

- Autoclavable Container Capacity

- 10 to 50 liters

- Glass Bottle Capacity

- 0.5 to 10 liters

- Material

- Stainless Steel

- Feed Method

- Powder transfer system/Vacuum-feed system

- Discharge Method

- On/off pumps, pressure-operated metering systems

- Shape

- Tank

- Vessel Capacity

- 30 to 20, 000 liters

- Container Size

- 10 to 50 liters

- Container Type

- Glass bottles

- Control System Type

- BioSCADA software

- Integration into CIP System

- Full integration

- Operation Mode

- Manual / Automatic

- Pumps

- On/off or fully-automated metering systems

- Feeding Method

- Vacuum-feed systems

- Sterilization

- Available

- Dust-Free System Type

- Cup-Hermann powder transfer system

- Stirrer Configuration

- Thorough yet gentle dissolution