Gentle mixing solution for gelatin powder

The fragile nature of gelatin makes it a challenging material to blend homogeneously. Friction during mixing leads to heat increments that disintegrate the peptide bonds in gelatin. Localized hot spots cause the particles to stick together and form lumps, undermining the entire gelatin production process.

Mix gelatin without exposing it to heat

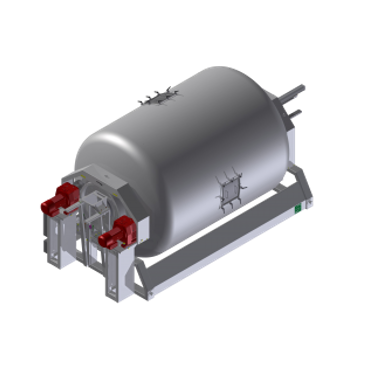

The Lindor gelatin mixer blends powders in a frictionless environment, preventing the buildup of temperatures. The fixed blades in the mixing drum gently guide the contents into a sliding motion driven by gravity. This approach avoids any physical contact with movable parts, such as paddles or ribbons, that exert heat stress on the particles.

The mixing technology blends gelatin powders without the risk of dissolving their chemical structures and prematurely activating gelatinization. The internal flow achieves a high grade of homogeneity, even at short mixing times of 3-5 minutes .

The unit is designed for quick and easy cleaning and is made of hygienic stainless steel. The gentle mixer range operates at low power, consuming fewer than 2kW per ton.

Benefits

- Full particle integrity without lump formation

- Frictionless motion eliminates hot spots

- Easy-to-clean

- Hygienic design without dead zones

- Batch sizes up to 25,000 liters